Capacitive biometric feature recognition sensor

A biometric identification and sensor technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of low resolution of fingerprint identification, inability to accurately identify fingerprints, and poor user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

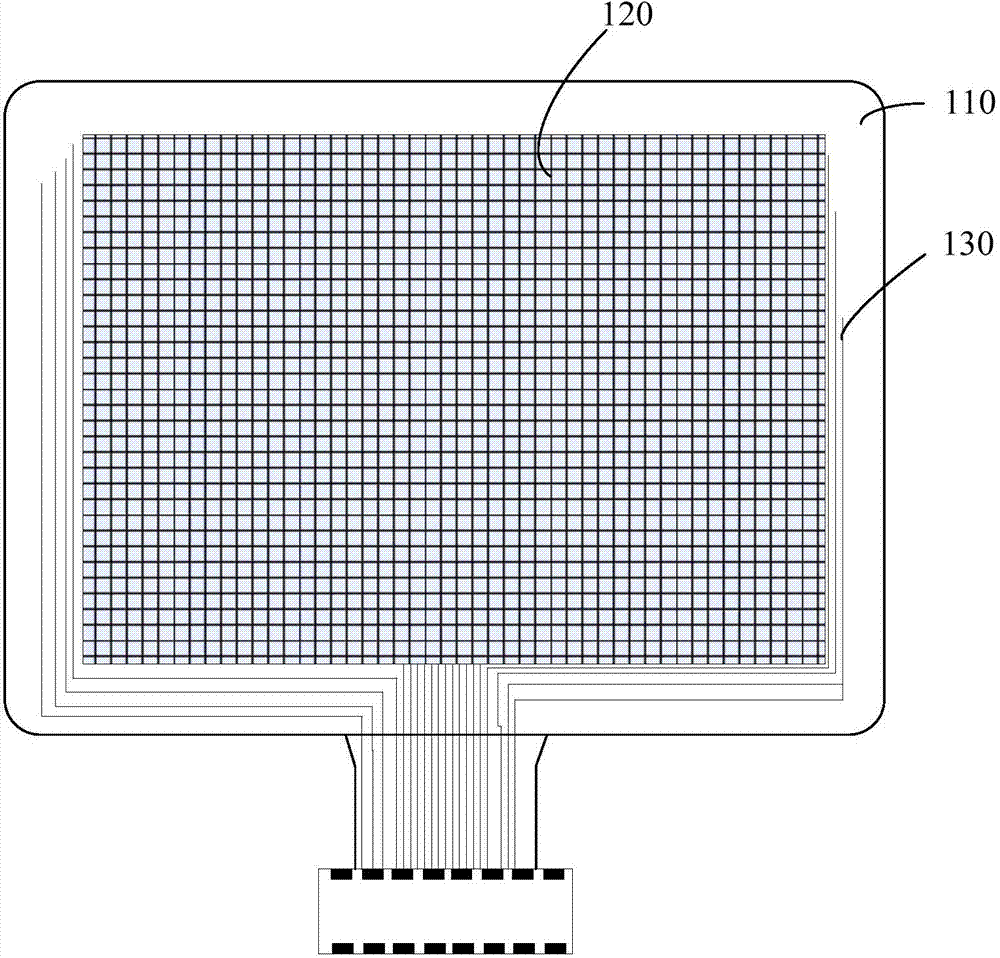

[0041] Please refer to figure 1 The capacitive biometric recognition sensor includes a base substrate 110, a conductive circuit 120 formed on the base substrate 110, and an electrode lead 130 connected to the conductive circuit 120.

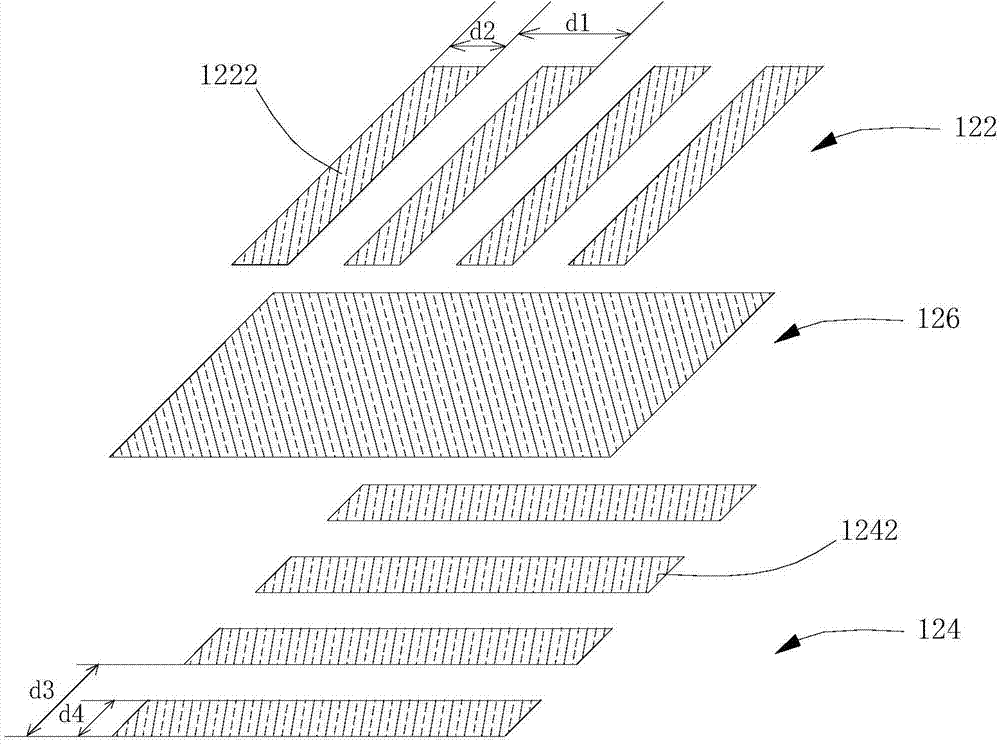

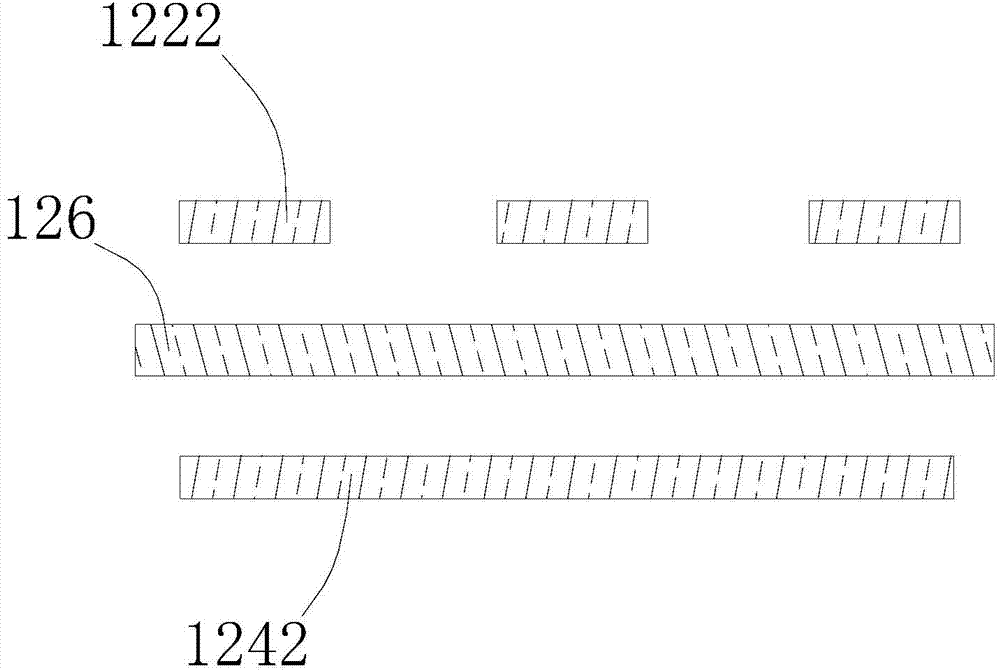

[0042] Please refer to figure 2 with image 3 The conductive circuit 120 includes an insulating layer 126 with a first conductive layer 122 and a second conductive layer 124 in between. In the present invention, the first conductive layer 122 is used as a sensing electrode, and the second conductive layer 124 is used as a driving electrode. However, it should be pointed out that the first conductive layer 122 and the second conductive layer 124 are not distinguished by themselves, and are specifically used as the kind of electrode. , Depends on the external chip.

[0043] The first conductive layer 122 includes a plurality of first electrode lines 1222 insulated and distributed from each other. The second conductive layer 124 includes a plurality of...

Embodiment 2

[0064] Please refer to Picture 11 , The capacitive biometric recognition sensor includes a plurality of first electrode wires 210 for forming a first conductive layer, a first insulating substrate 220, an insulating layer 230, and a plurality of second electrode wires 240 for forming a second conductive layer And a second insulating substrate 250. The first electrode wire 210 is disposed on the first insulating substrate 220, the second electrode wire 240 is disposed on the second insulating substrate 250, and the insulating layer 230 separates the first electrode wire 210 from the second electrode wire 240. The material of the first insulating substrate 220 and the second insulating substrate 250 can be the same or different, and can be selected from PET (Polyethylene terephthalate), PMMA (Polymethyl Methacrylate, polymethyl methacrylate). Ester), PC (Polycarbonate, polycarbonate), COC (Cyclo Olefin Copolymers), COP (Cyclo Olefin Polymers, cyclic olefin copolymer) and other o...

Embodiment 3

[0066] Please refer to Picture 12 As an improvement of the second embodiment, in order to improve the adhesion performance between the first electrode line 210 and the first insulating substrate 220, and to improve the adhesion performance between the second electrode line 240 and the second insulating substrate 250, the first A first matching layer 260 is additionally provided between the electrode wires 210 and the first insulating substrate 220, and a second matching layer 270 is additionally provided between the second electrode wires 240 and the second insulating substrate 250. The material of the first electrode line 210 and the second electrode line 240 can be metal or a mixture of metal and organic resin with continuous electrical conductivity. The material of the first matching layer 260 and the second matching layer 270 can be ITO (oxidized Indium tin), the thickness is 10nm ~ 2μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com