Preparation method and substrate of transparent single crystal Aln, ultraviolet light-emitting device

A technology for light-emitting devices and single crystals, which is used in semiconductor devices, semiconductor/solid-state device manufacturing, and electrical components. The effect of avoiding oxidation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

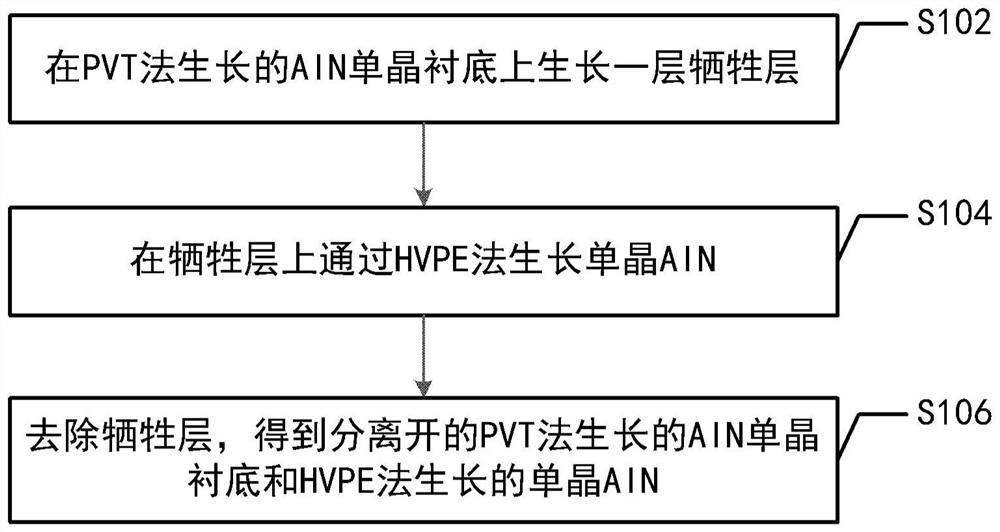

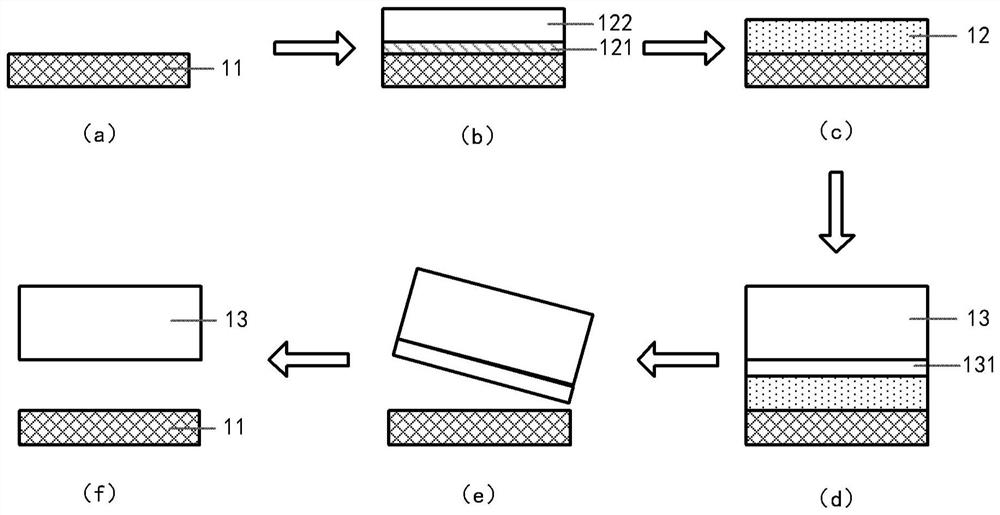

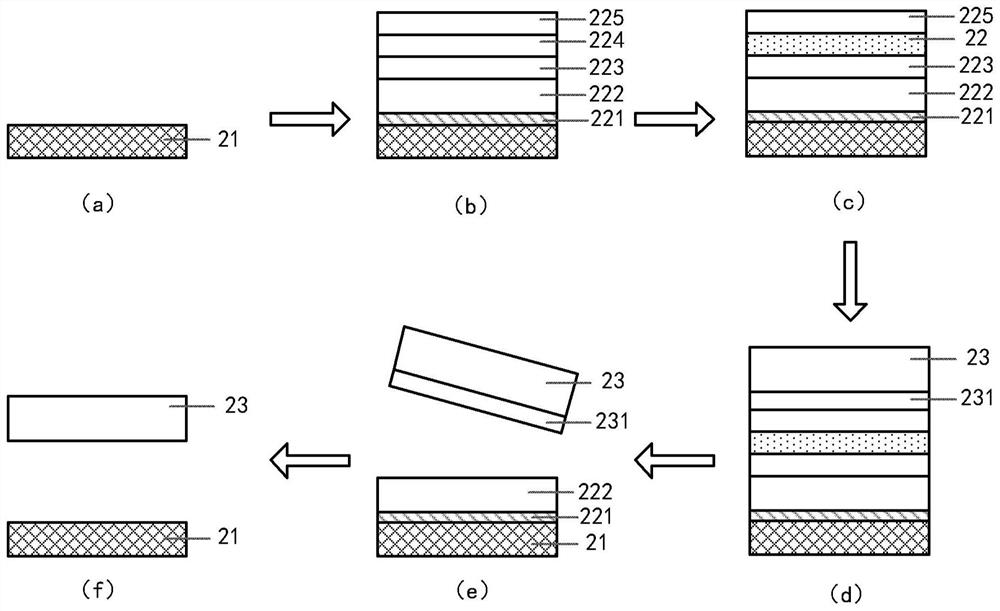

[0047] The disclosure provides a method for preparing transparent single crystal AlN, a substrate, and an ultraviolet light-emitting device. A sacrificial layer is grown on the AlN single crystal substrate grown by the PVT method, and then a single crystal is grown on the sacrificial layer by the HVPE method. AlN, and remove the sacrificial layer to obtain separated AlN single crystal substrate grown by PVT method and single crystal AlN grown by HVPE method, no need for chemical mechanical polishing, only need to simply remove the thinner sacrificial layer, fast and effective, At the same time, the oxidation problem caused by CMP is avoided, and the AlN single crystal substrate grown by the PVT method is preserved, and can be returned to the furnace to continue making seed crystals for epitaxy to realize recycling; the oxygen and carbon of the obtained single crystal AlN grown by the HVPE method The content of impurities is very low, and it is transparent single crystal AlN, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com