Composite backboard of photovoltaic module

A photovoltaic module and backplane technology, applied in photovoltaic power generation, film/sheet adhesives, electrical components, etc., can solve the negative impact of photovoltaic cell conversion efficiency, poor water vapor permeability, flexibility, and deformation resistance Problems such as poor performance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

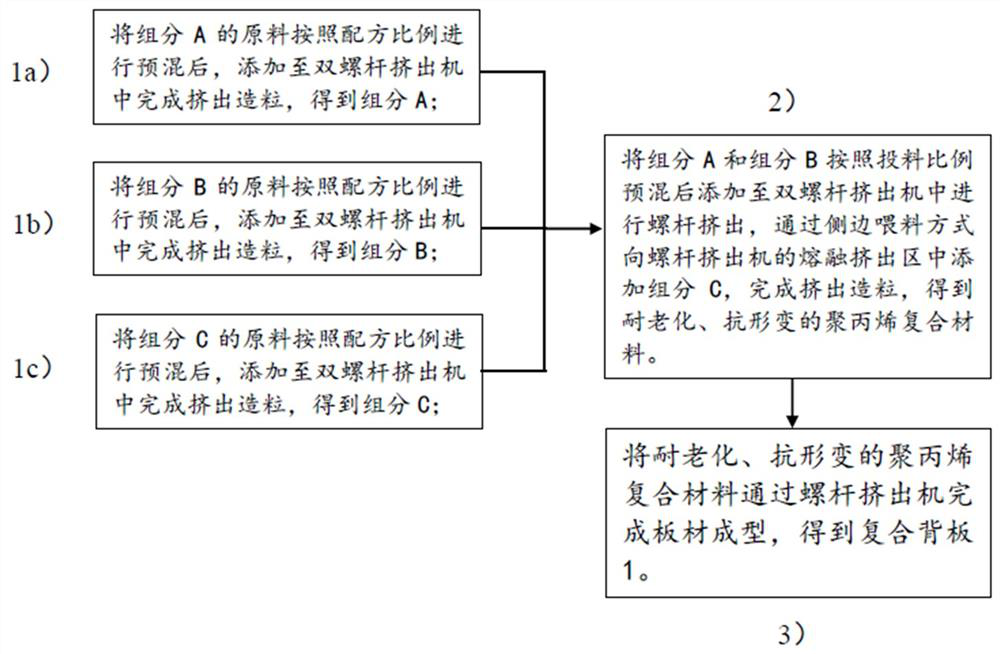

Method used

Image

Examples

Embodiment 1

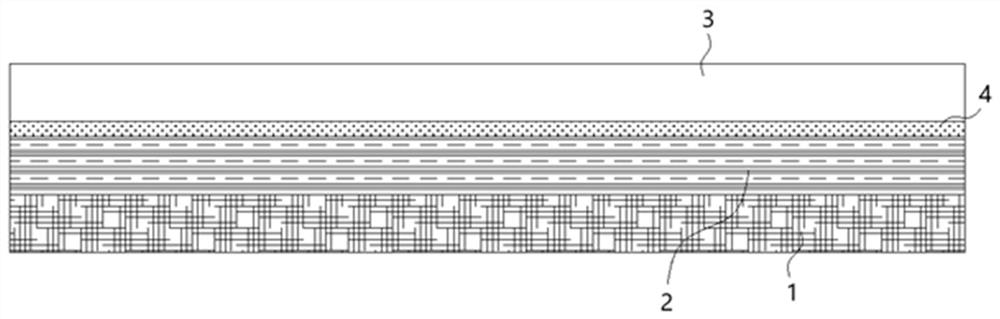

[0030] Example 1: see figure 1A composite backplane 1 of a photovoltaic module is shown, the photovoltaic module backplane 1 is in direct contact with the battery string layer 2, and is packaged as a whole with the front glass layer 3, the front EVA layer 4, and the battery string layer 2 through a lamination process, The temperature of the lamination process is 220°C, and the lamination time is 4-8 minutes. At this time, the composite backplane 1 is cross-linked and solidified; preferably, in this embodiment, the thickness of the composite backplane 1 is 1-6mm, more It is preferably 2-4mm; the battery string layer adopts crystalline silicon battery slices.

[0031] Among them, in this embodiment, the composite backsheet 1 adopts a single-layer structure, and the raw materials of the single-layer structure include the following raw materials in weight percentage:

[0032] 65% of component A: including polypropylene resin (purchased from Fushun Petrochemical, type EPS30R, melt...

Embodiment 2

[0044] Embodiment 2: The rest of the technical solutions of this embodiment are the same as those of Embodiment 1, the difference is that, in this embodiment, the composite backboard includes raw materials in the following weight percentages:

[0045] 55% of component A: 35% of component B: 10% of component C.

Embodiment 3

[0046] Embodiment 3: The remaining technical solutions of this embodiment are the same as those of Embodiment 1, the difference is that, in this embodiment, the composite backboard includes raw materials in the following weight percentages:

[0047] 60% of component A: 30% of component B: 10% of component C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com