Preparation method of tin dioxide-based gas sensor and carbon monoxide gas sensor system

A gas sensor, tin dioxide technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as poor resistance to ethanol interference, and achieve the effects of high working temperature, improved response speed, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

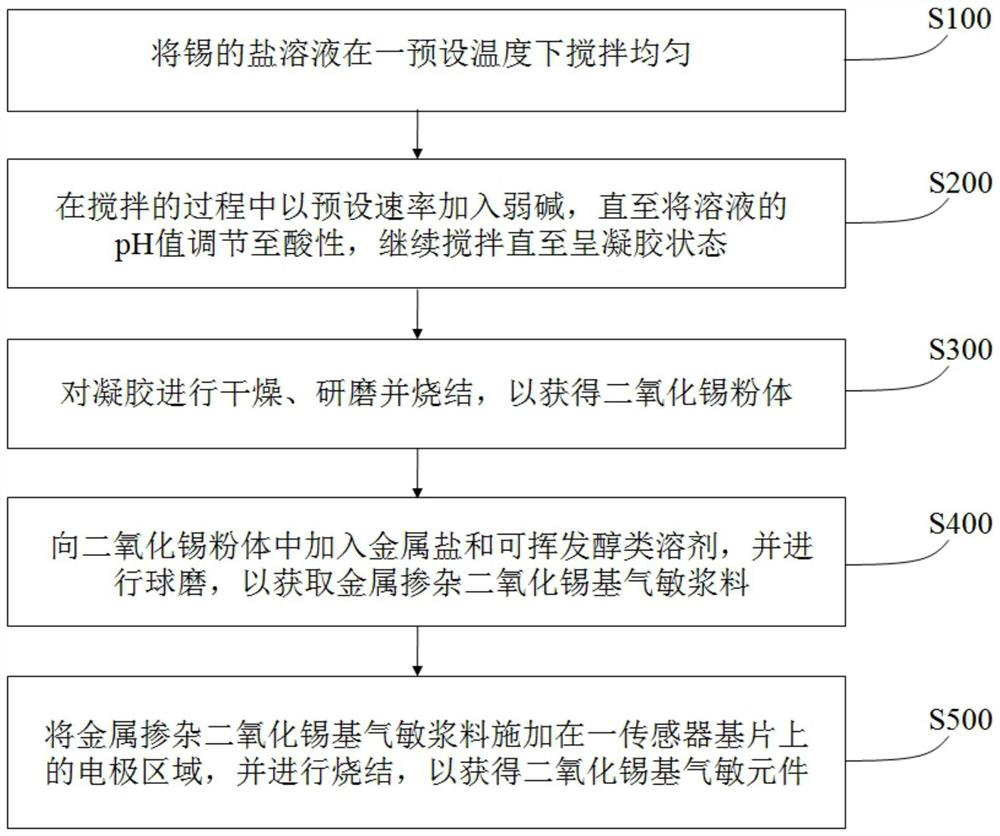

[0033] figure 1 A schematic flowchart showing a method for preparing a tin dioxide-based gas sensor according to an embodiment of the present invention. Such as figure 1 Shown, this preparation method comprises the steps:

[0034] S100, stirring the tin salt solution evenly at a preset temperature;

[0035] S200, adding a weak base at a preset rate during the stirring process until the pH value of the solution is adjusted to 3-4, and continuing to stir until it is in a gel state;

[0036] S300, drying, grinding and sintering the gel to obtain tin dioxide powder;

[0037] S400, adding a metal salt and a volatile alcohol solvent to the tin dioxide powder, and performing ball milling to obtain a metal-doped tin dioxide-based gas-sensitive slurry;

[0038] S500. Apply metal-doped tin dioxide-based gas-sensing paste to an electrode region on a sensor substrate, and sinter to obtain a tin-dioxide-based gas-sensing element.

[0039] In step S100, the tin salt solution may be, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com