How to make vane pump vane

A manufacturing method and technology of vane pumps, which are applied in the field of vane pump vane production, and can solve problems such as insufficient smoothness of finished vane products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

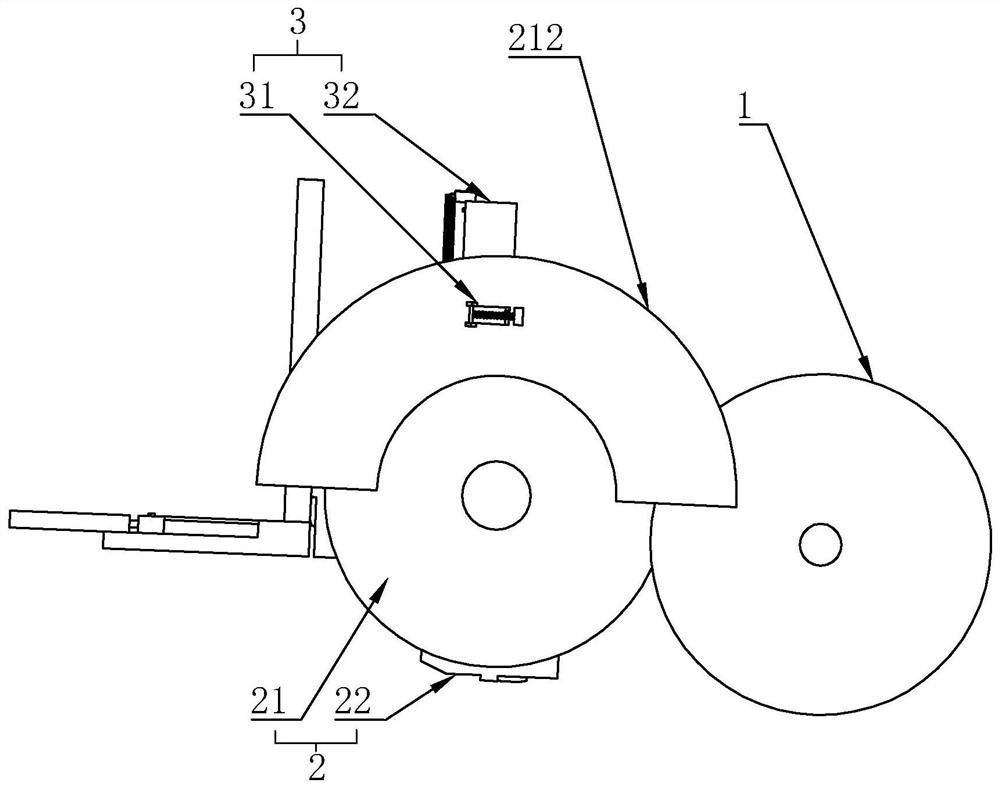

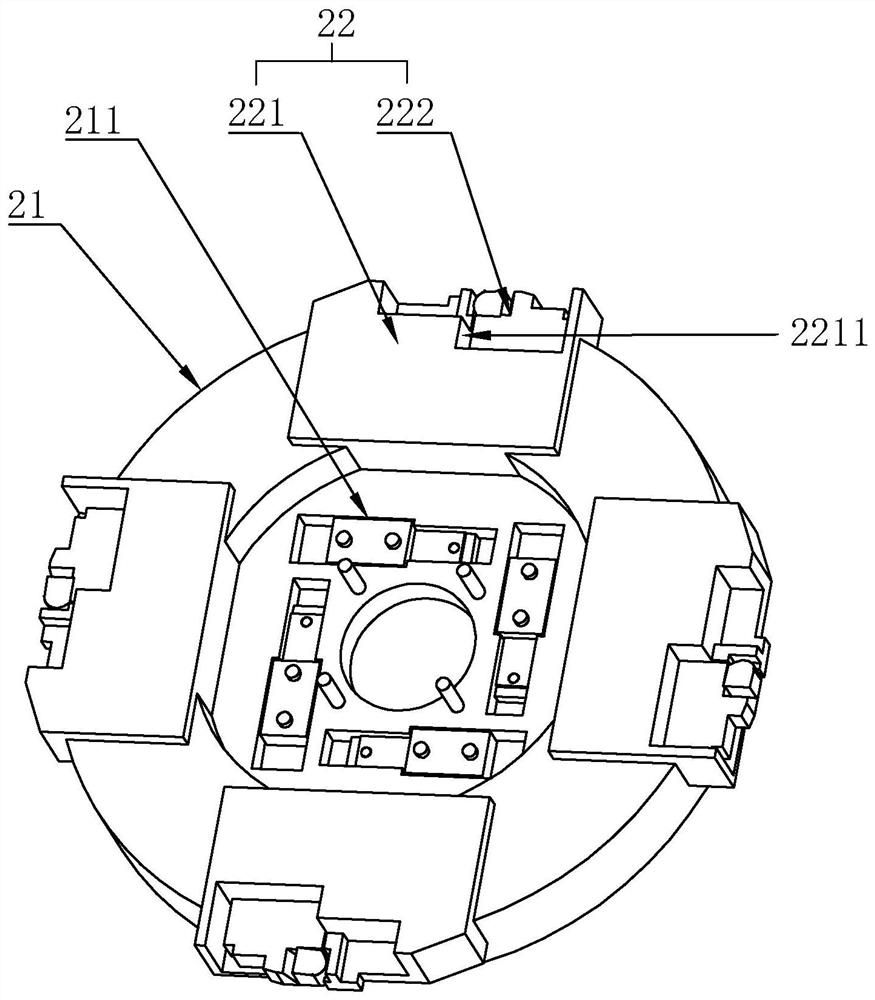

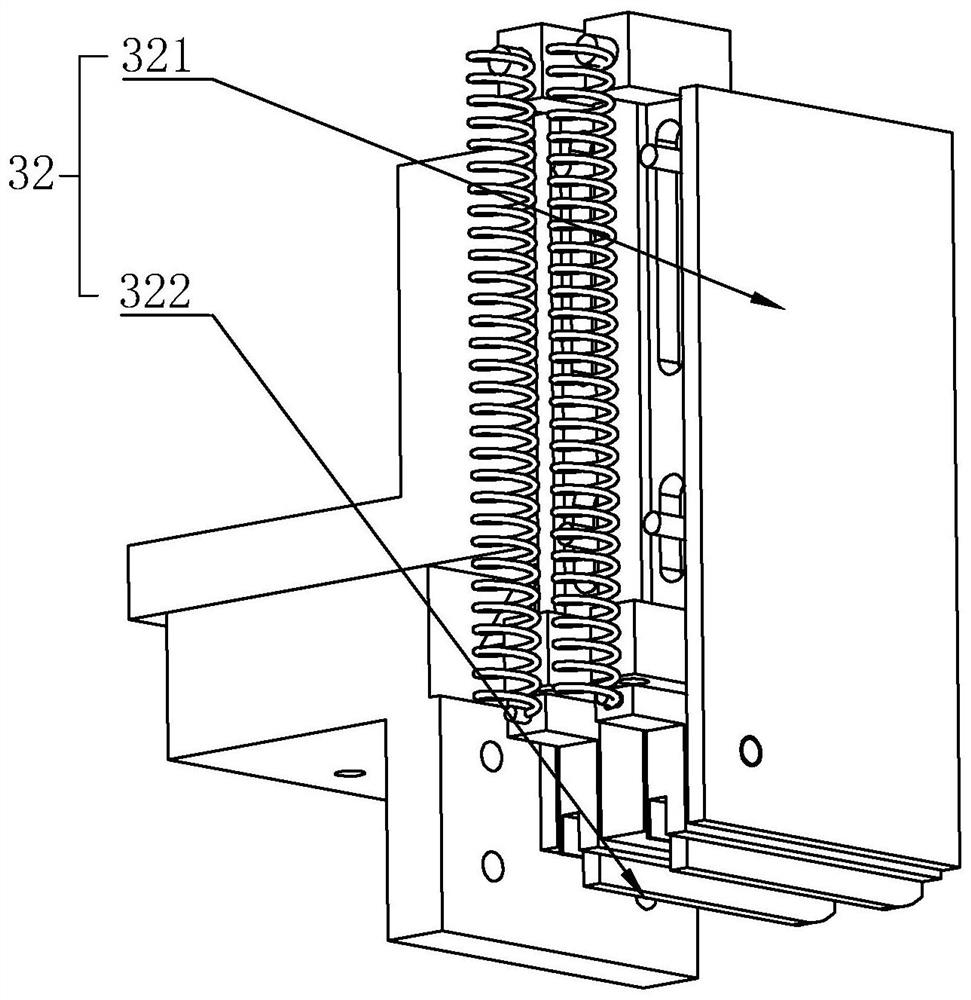

[0042]As a specific embodiment, the position adjusting mechanism 3 includes left and right adjusting assemblies 31 and up and down adjustment assemblies 32. When the collet 22 is moved to the position adjustment mechanism 3, the chuck 22 releases the clamped blade, up and down The adjustment assembly 32 adjusts the upper and lower position of the blade, and the left and right adjustment assembly 31 adjust the left and right position of the blade, the up and down adjusting assembly 32 includes adjusting the base 321 and the adjustment block 322, the adjustment base 321 fixed to the mounting plate 212. Above, the adjustment block 322 is flipped to adjust the lower side of the base 321, and is resiliently coupled to the adjustment base 321, when the chuck 22 is moved to the adjustment base 321, adjust the pressure block 322 The blade on the collet 22 is fitted with the collet 22 to adjust the upper and lower position of the blade, and the position adjusting mechanism 3 in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com