A kind of composite artificial stone table top and preparation method thereof

A stone table and panel technology, which is applied in the field of composite artificial stone table top and its preparation, can solve the problems of poor heat resistance, easy breakage, fast aging, etc., and achieves good heat resistance, high bending resistance and compressive strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

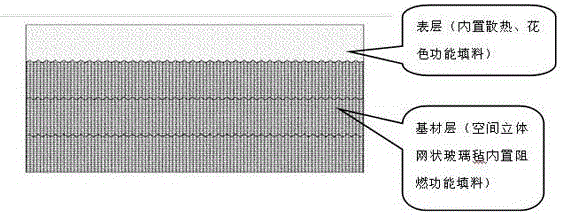

Method used

Image

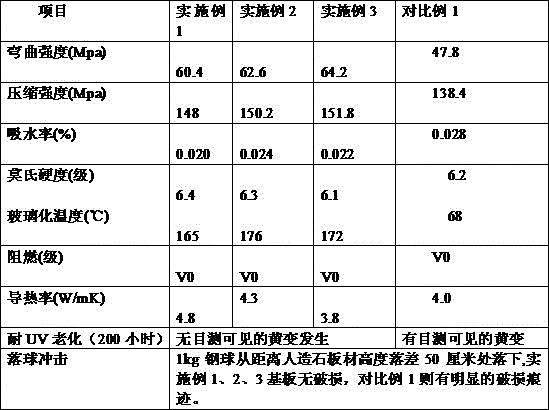

Examples

Embodiment 1

[0032] Prepare composite artificial stone slab surface materials (×1kg) according to the following proportions by weight: surface quartz sand 60, surface quartz powder 5, curing agent 0.2, accelerator 0.05, solvent 3, multifunctional epoxy resin 7, coupling agent 0.02 , pigment 0.5, thermal powder 5.

[0033] The quartz sand is 8 mesh, the quartz powder is 60 mesh, the curing agent is dicyandiamide, the accelerator is 2-methylimidazole, and the solvent is N,N-dimethylformamide, The multifunctional epoxy resin is phenol novolac epoxy resin (Nan Ya Epoxy Co., Ltd. 638), the coupling agent is KH550 silane coupling agent, the pigment is iron red, and the heat conducting powder is aluminum nitride.

[0034] Prepare the composite artificial stone slab substrate layer raw materials (×4kg) according to the following weight ratio: aluminum hydroxide 60, substrate layer quartz powder 5, curing agent 0.2, accelerator 0.10, solvent 4, multifunctional epoxy resin 15, Coupling agent 0.02, ...

Embodiment 2

[0043] Prepare composite artificial stone plate surface layer raw materials according to the following weight ratio (×1kg): surface layer quartz sand 90, surface layer quartz powder 40, curing agent 0.5, accelerator 0.28, solvent 3, multifunctional epoxy resin 14, coupling agent 0.05 , Pigment 0.6, thermal powder 3.

[0044] The quartz sand is 16 mesh, the quartz powder is 100 mesh, the curing agent is m-phenylenediamine, the accelerator is N,N,2-methylimidazole, the solvent is butanone, and the The multifunctional epoxy resin is o-cresol novolac epoxy resin (Nan Ya Epoxy Co., Ltd. 704), the coupling agent is KH550 silane coupling agent, the pigment is iron yellow, and the heat conducting powder is aluminum powder.

[0045] Prepare the composite artificial stone slab substrate layer raw materials (×6kg) according to the following weight ratio: aluminum hydroxide 90, substrate layer quartz powder 40, curing agent 0.5, accelerator 0.2, solvent 5, multifunctional epoxy resin 25, ...

Embodiment 3

[0054] Prepare composite artificial stone slab surface material (×1kg) according to the following proportions by weight: surface quartz sand 75, surface quartz powder 22.5, curing agent 3, accelerator 0.15, solvent 4, multifunctional epoxy resin 12, coupling agent 0.035 , Pigment 0.3, thermal conductive powder 4.

[0055] The quartz sand is 26 mesh, the quartz powder is 140 mesh, the curing agent is novolac (Shandong Shengquan Chemical, SH-1066), the accelerator is 2-phenylimidazole, and the solvent is cyclo Hexanone, the multifunctional epoxy resin is bisphenol A type novolac epoxy resin (Changchun Resin Factory BNE200), the coupling agent is KH792 silane coupling agent, the pigment is phthalocyanine blue, and the heat conducting powder is aluminum oxide powder .

[0056] Prepare the composite artificial stone slab substrate layer raw materials (×8kg) according to the following weight ratio: aluminum hydroxide 75, substrate layer quartz powder 22.5, curing agent 3, accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com