A manufacturing process of dreamy color-changing fabric

A production process and fabric technology, which is applied in the production process of dreamy color-changing fabrics, to achieve the effect of good warmth retention, stable loop structure, and plump and thick hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

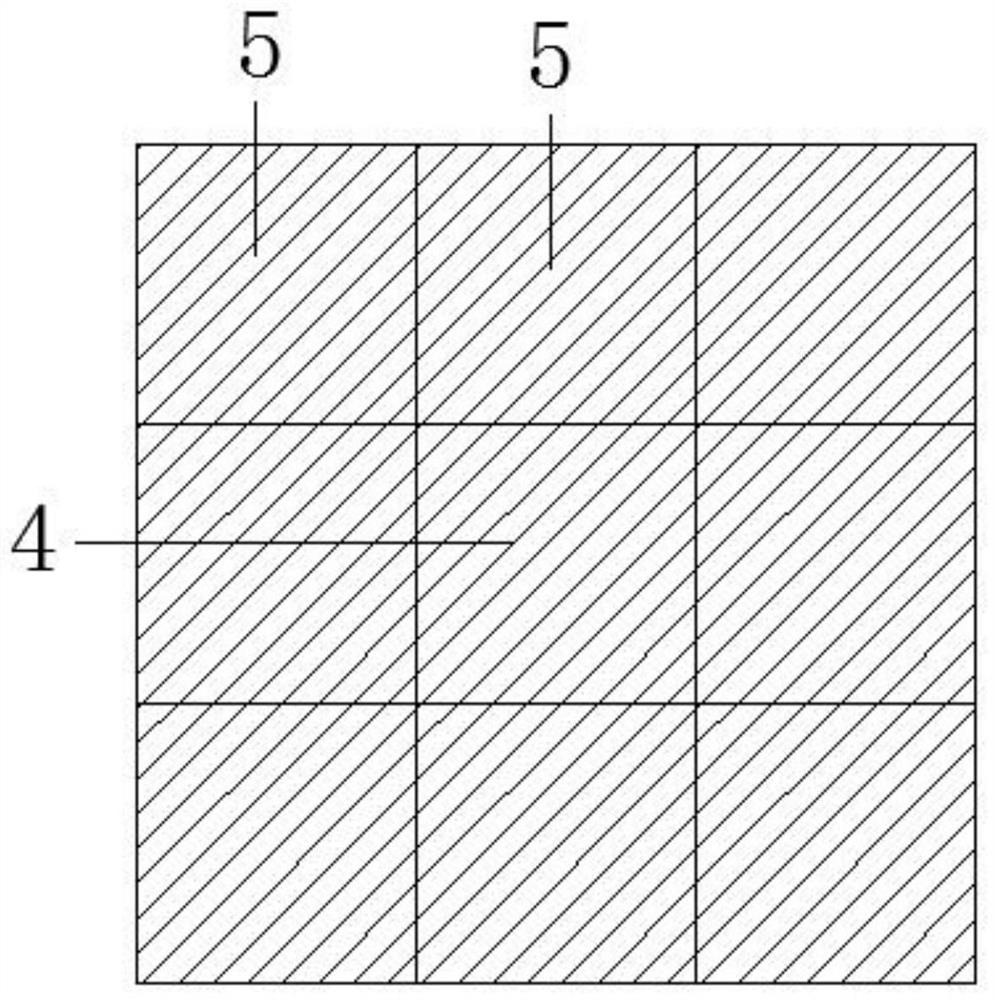

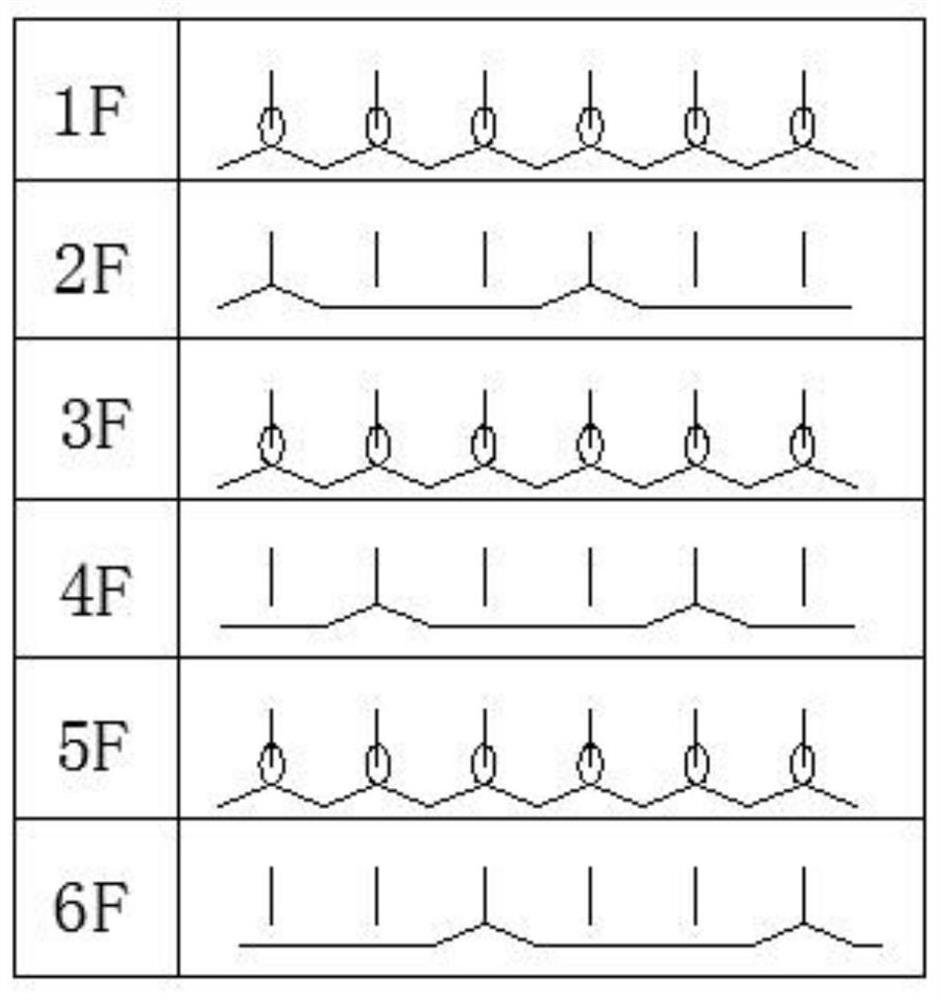

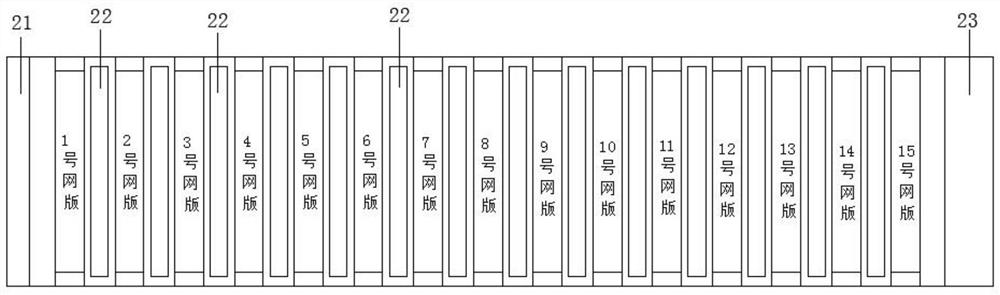

[0029] Such as Figure 1-3 The production process of a new dream color-changing fabric is shown, including two steps of organic cotton dyeing and organic cotton printing;

[0030] 1) Organic cotton dyed

[0031] a. Put organic cotton fabric and organic cotton pre-treatment liquid into the main vat, and raise the temperature to 50°C; add organic cotton pre-treatment liquid into the auxiliary vat, and pump it directly into the main vat; then put it into the main vat The temperature of the pre-treatment liquid in the main vat is raised to 70°C, and 8g / L hydrogen peroxide is added to the auxiliary vat, which is pumped directly into the main vat; after the temperature of the pre-treatment liquid in the main vat is raised to 98°C, the fabric is After heat preservation at 98°C for 40 minutes, drain water; wherein, the organic cotton pretreatment liquid preferably includes 2g / L caustic soda, 1g / L high-efficiency penetrating agent and 1g / L high-efficiency refining degreasing agent. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com