A kind of production method of two-color wool-like polyester fiber

A production method, wool polyester technology, applied in fiber processing, single-component copolyester rayon, filament/thread forming, etc., can solve the problem of reduced surface fiber differential shrinkage, high shrinkage FDY shrinkage loss, Fleece is easy to lodging and other problems, to achieve good wool-like effect and good shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Production of 340D / 360F two-color wool-like polyester fiber: monofilament A adopts 268dtex / 288f flat ordinary polyester pre-oriented yarn, monofilament fineness is 0.84dpf, strength is 2.5cn / dtex, and elongation is 138%; monofilament B adopts 270dtex / 48f flat cationic modified polyester pre-oriented yarn, monofilament fineness 5.0dpf, strength 2.2cn / dtex, elongation 135%; monofilament C adopts 64dtex / 24f circular section high-shrinkage FDY yarn, monofilament fineness It is 2.4dpf, the strength is 3.9cn / dtex, the elongation is 30%, and the boiling water shrinkage is 39.5%.

[0054] step:

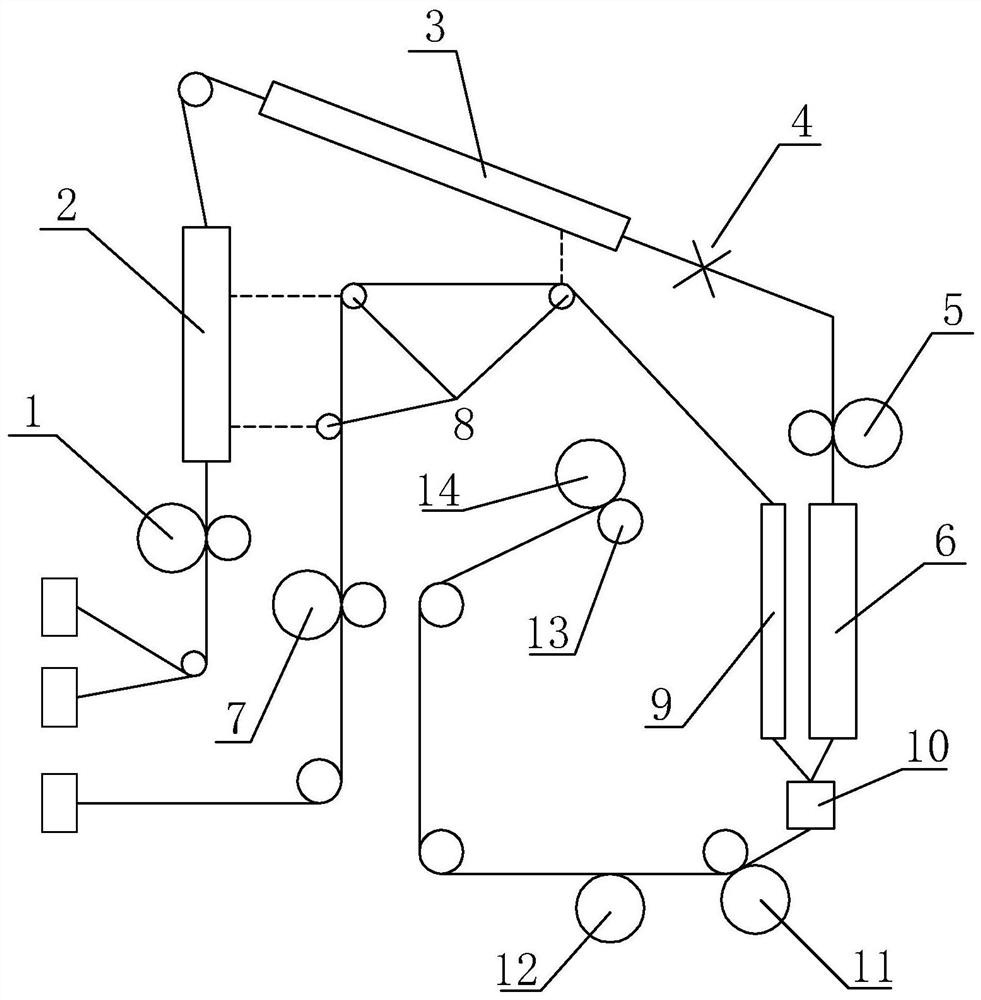

[0055] 1) After merging monofilament A and monofilament B, they go through the drafting of one roller, the deformation of one hot box, the cooling of cooling plate, the false twisting of false twister (stacked disc type), the drafting of two rollers, and the second The shaping of the hot box.

[0056] 2) At the same time, the monofilament C is sequentially drawn by the zero roller, g...

Embodiment 2

[0068] Production of 180D / 192F two-color wool-like polyester fiber: monofilament A adopts 137dtex / 144f flat ordinary polyester pre-oriented yarn, monofilament fineness is 0.86dpf, strength is 2.2cn / dtex, and elongation is 135%; monofilament B adopts 133dtex / 36f flat cationic modified polyester pre-oriented yarn, single filament fineness 3.3dpf, strength 2.3cn / dtex, elongation 136%; raw material C uses 33dtex / 12f circular section high-shrinkage FDY filament, single filament fineness is 2.5dpf, strength 4.0cn / dtex, elongation 28%, boiling water shrinkage 38%.

[0069] step:

[0070] 1) After merging monofilament A and monofilament B, they go through the drafting of one roller, the deformation of one hot box, the cooling of cooling plate, the false twisting of false twister (apron type), the drafting of two rollers, and the second The shaping of the hot box.

[0071] 2) At the same time, the monofilament C is sequentially drawn by the zero roller, guided by the bypass yarn guid...

Embodiment 3

[0082] Embodiment 3 (fiber cross section is different)

[0083] Production of 340D / 360F two-color wool-like polyester fiber: Monofilament A adopts conventional polyester pre-oriented yarn with a circular cross-section of 265dtex / 288f, the monofilament fineness is 0.83dpf, the strength is 2.6cn / dtex, and the elongation is 136%; Yarn B adopts cationic modified polyester pre-oriented yarn with circular section of 273dtex / 48f, monofilament fineness is 5.1dpf, strength is 2.4cn / dtex, and elongation is 139%; monofilament C adopts circular section of 64dtex / 24f with high shrinkage FDY yarn, the single filament fineness is 2.4dpf, the strength is 3.9cn / dtex, the elongation is 30%, and the boiling water shrinkage is 39.5%.

[0084] step:

[0085] 1) After merging monofilament A and monofilament B, they go through the drafting of one roller, the deformation of one hot box, the cooling of cooling plate, the false twisting of false twister (stacked disc type), the drafting of two rollers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com