Method for preparing n-butane from mixed butane

A technology of mixing C4 and n-butane, which is applied in the field of mixing C4 and n-butane, which can solve the problems affecting the comprehensive economic benefits of the enterprise, increasing the storage and transportation costs of the enterprise, and achieving controllable production process conditions and shortening hydrogenation Effect of reaction time and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

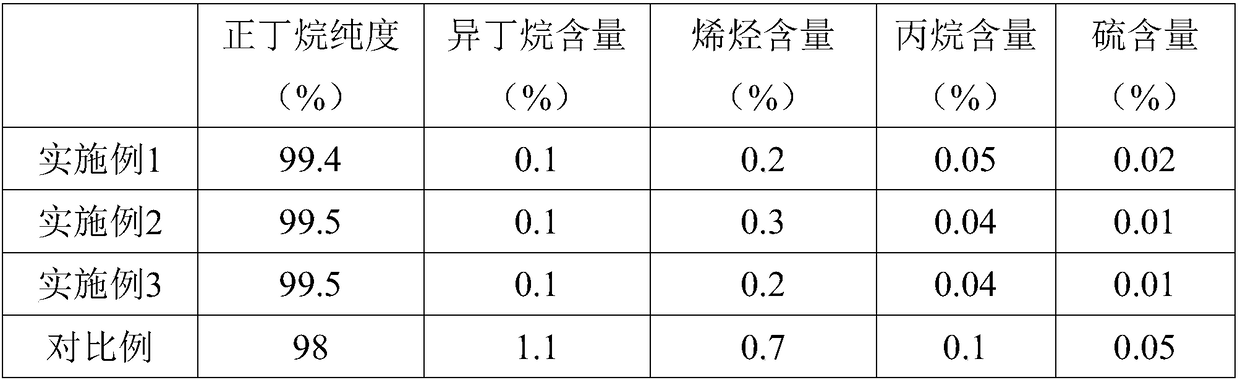

Examples

Embodiment 1

[0030] A method for preparing n-butane by mixing carbon four, comprising the following steps:

[0031] (1) Put the by-product C4 produced in the production process of petroleum refining, steam cracking to ethylene, methanol to olefins, etc. into a fixed bed reactor, add a hydrogenation catalyst to the reactor, and circulate hydrogen to carry out hydrogenation reaction;

[0032] (2) Mix the product after the reaction of step (1) and the desulfurizer evenly, send it into the distillation tower, control the temperature at the bottom of the tower to be 85°C, and the temperature at the top of the tower to be 150°C, and the sulfur-containing mixture flows out from the bottom of the tower, and the desulfurized The product flows out from the bottom of the tower;

[0033] (3) Send the desulfurized product into the rectification tower, control the temperature at the bottom of the rectification tower to 110°C, the middle to 160°C, and the top to 170°C, collect propane at the top of the ...

Embodiment 2

[0050] A method for preparing n-butane by mixing carbon four, comprising the following steps:

[0051](1) Put the by-product C4 produced in the production process of petroleum refining, steam cracking to ethylene, methanol to olefins, etc. into a fixed bed reactor, add a hydrogenation catalyst to the reactor, and circulate hydrogen to carry out hydrogenation reaction;

[0052] (2) Mix the product after the reaction of step (1) and the desulfurizer evenly, send it into the distillation tower, control the temperature at the bottom of the tower to be 100°C, and the temperature at the top of the tower to be 130°C, the sulfur-containing mixture flows out from the bottom of the tower, and the desulfurized The product flows out from the bottom of the tower;

[0053] (3) Send the desulfurized product into the rectification tower, control the temperature at the bottom of the rectification tower to 100°C, the middle to 150°C, and the top to 180°C, collect propane at the top of the rect...

Embodiment 3

[0070] A method for preparing n-butane by mixing carbon four, comprising the following steps:

[0071] (1) Put the by-product C4 produced in the production process of petroleum refining, steam cracking to ethylene, methanol to olefins, etc. into a fixed bed reactor, add a hydrogenation catalyst to the reactor, and circulate hydrogen to carry out hydrogenation reaction;

[0072] (2) Mix the product after the reaction of step (1) and the desulfurizer evenly, and send it into the distillation tower. The product flows out from the bottom of the tower;

[0073] (3) Send the desulfurized product into the rectification tower, control the temperature at the bottom of the rectification tower to 130°C, the middle to 140°C, and the top to 160°C, collect propane at the top of the rectification tower, collect n-butane at the bottom, and collect n-butane at the middle Isobutane;

[0074] (4) the isobutane collected in step (3) is carried out normalization reaction under catalyst action t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com