Production method of titanium alloy seamless tubes used for tubing coupling

A production method, titanium alloy technology, applied in metal rolling and other directions, can solve problems such as poor plasticity, poor dimensional accuracy, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

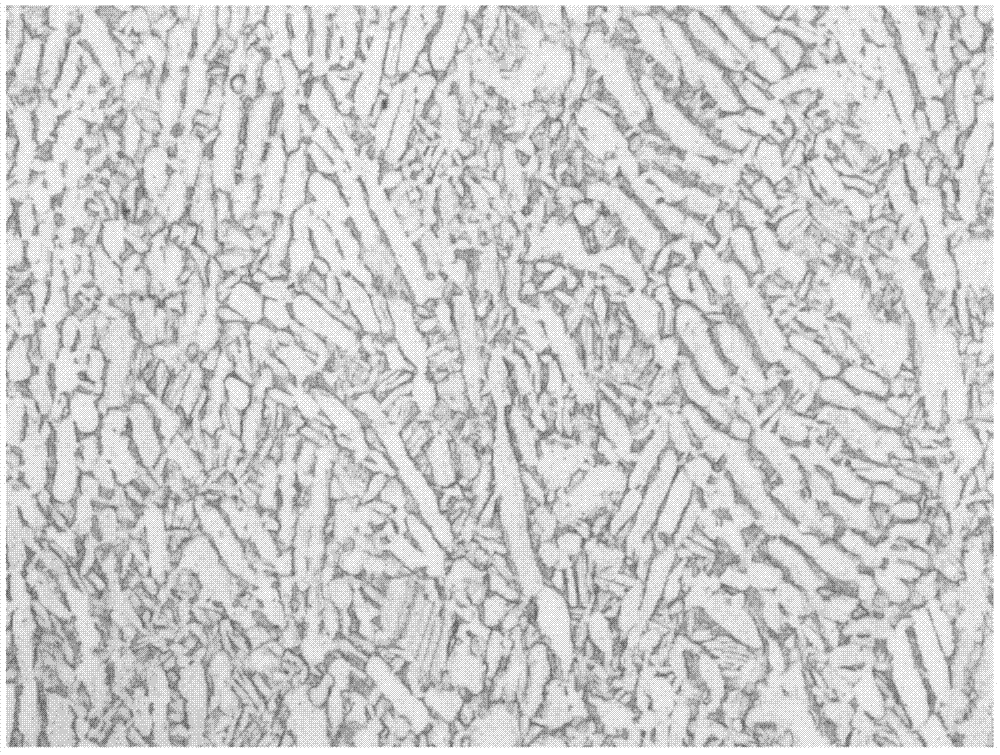

Image

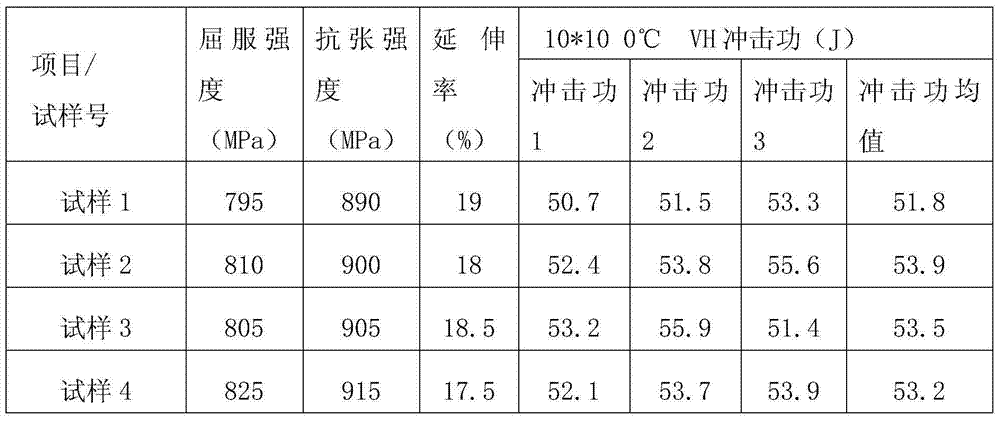

Examples

Embodiment 1

[0104] Taking the production of seamless pipes for 110X20TC4 tubing couplings as an example, the production process is as follows:

[0105] A, material preparation

[0106] Purchase TC4 titanium alloy whose chemical composition complies with GB / T3620.1-2007, forge and machine it into a round billet with a diameter of 160mm, and punch centering holes at both ends by machining, d=50±2mm, depth 45mm.

[0107] B, ring furnace heating

[0108] Heating with natural gas, the air-fuel ratio is set at 12:1. When heating at low temperature after entering the furnace, the temperature of the heat recovery section and the preheating section are 760-790°C, and the heating time is 120 minutes; 880°C, the heating time is 90 minutes; when heating at high temperature, the temperature of the third heating stage is 950-980°C; when the temperature is equalized, the soaking stage 1 and the second stage are 940-980°C, and the heating time is 90 minutes.

[0109] C, skew rolling piercing

[0110] ...

Embodiment 2

[0126] Taking the production of seamless pipes for 139X23TC4 oil pipe couplings as an example, the production process is as follows

[0127] A, material preparation

[0128] Purchase TC4 titanium alloy whose chemical composition complies with GB / T3620.1-2007, forge and machine it into a round billet with a diameter of 200mm, and punch centering holes at both ends by machining, d=50±2mm, depth 45mm.

[0129] B, ring furnace heating

[0130] Heating with natural gas, the air-fuel ratio is set at 12:1. When heating at low temperature after entering the furnace, the temperature of the heat recovery section and the preheating section are 760-790°C, and the heating time is 140 minutes; 880°C, the heating time is 110 minutes; when heating at high temperature, the temperature of the third heating stage is 950-980°C; when the temperature is equalized, the soaking stage 1 and the second stage are 940-980°C, and the heating time is 110 minutes.

[0131] C, skew rolling piercing

[013...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Straightness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com