Industrial production method for ethylene propylene diene rubber molded sealed cell sponge rubber

A technology of EPDM rubber and closed-cell sponge, which is applied in the field of EPDM rubber molded closed-cell sponge rubber, can solve the problems that industrial production cannot meet the requirements, is prone to scorching, and has a large calorific value, and achieves production The effect of controllable conditions and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

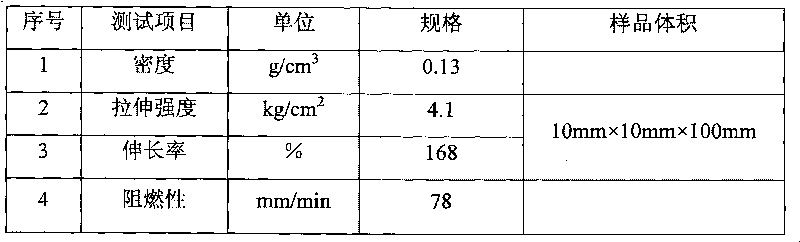

Embodiment 1

[0030] Weigh materials according to the following formula: EPDM: 500g, carbon black: 250g, naphthenic oil: 250g, pro-BZ: 0.6g, pro-D: 0.5g, pro-TRA: 0.6g, pro-M: 0.5g, stearic acid: 8g, Zinc Oxide: 15g, Ac: 30g, S: 0.8g

[0031] Molding: Control the temperature of the two rollers of the open mill to be kept below 50°C. The raw rubber is smelted twice when the roller distance scale is 1, and then the roller distance is adjusted to 0 scale, and the triangular bag is made 4 to 6 times. Until the glue is translucent.

[0032] Mixing: Put the qualified EPDM rubber into the internal mixer and pressurize it. When the temperature rises to 80°C, raise the pressure cover, add carbon black, naphthenic oil and foaming aids, vulcanization accelerators, anti-aging After the pressure cover is semi-closed and empty for about 1 minute, the upper pressure cover is completely pressed, and the glue is removed when the temperature rises to 120°C, and it is sent to the two-roller for kneading. Th...

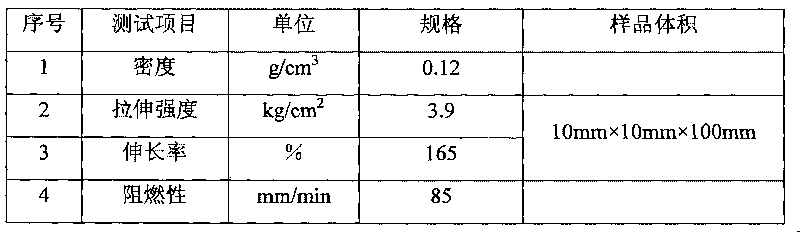

Embodiment 2

[0038] Weigh materials according to the following formula: EPDM: 500g, carbon black: 250g, naphthenic oil: 100g, pro-BZ: 0.6g, pro-D: 0.5g, pro-TRA: 0.6g, pro-M: 0.5g, stearic acid: 4g, Zinc Oxide: 8g, Ac: 16g, S: 13g

[0039] Plastic refining: control the temperature of the two rollers of the open mill, refine the raw rubber for 2 times when the roller distance scale is 1, then adjust the roller distance to 0 scale, make triangular bags 4 to 6 times, until the rubber material is Translucent.

[0040] Mixing: put the qualified EPDM rubber into the internal mixer and pressurize it. When the temperature rises to 85°C, raise the pressure cover, add carbon black, naphthenic oil, foaming aids, vulcanization accelerators, anti-aging After the pressure cover is semi-closed for about 1 minute, press the upper pressure cover completely, and when the temperature rises to 118°C, the glue will be removed and sent to the two rollers for kneading. The kneaded rubber material is kneaded on...

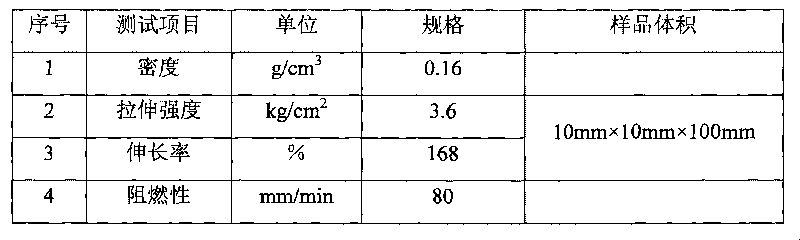

Embodiment 3

[0045]Weigh the materials according to the following formula: EPDM: 500g, carbon black: 250g, naphthenic oil: 100, promote BZ: 0.6g, promote D: 0.5g, promote TRA: 0.6g, promote M: 0.5g, stearic acid: 8g, Zinc Oxide: 8g, Ac: 16g, S: 5g

[0046] Plastic refining: control the temperature of the two rollers of the open mill, refine the raw rubber for 2 times when the roller distance scale is 1, then adjust the roller distance to 0 scale, make triangular bags 4 to 6 times, until the rubber material is Translucent.

[0047] Mixing: Put the qualified EPDM rubber into the internal mixer and pressurize it. When the temperature rises to 90°C, raise the pressure cover, add carbon black, naphthenic oil and foaming aids, vulcanization accelerators, anti-aging agent. After the pressure cover is half-closed and empty for about 1 minute, the upper pressure cover is completely pressed, and when the temperature rises to 110°C, the glue is removed and sent to the two-roller for kneading. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com