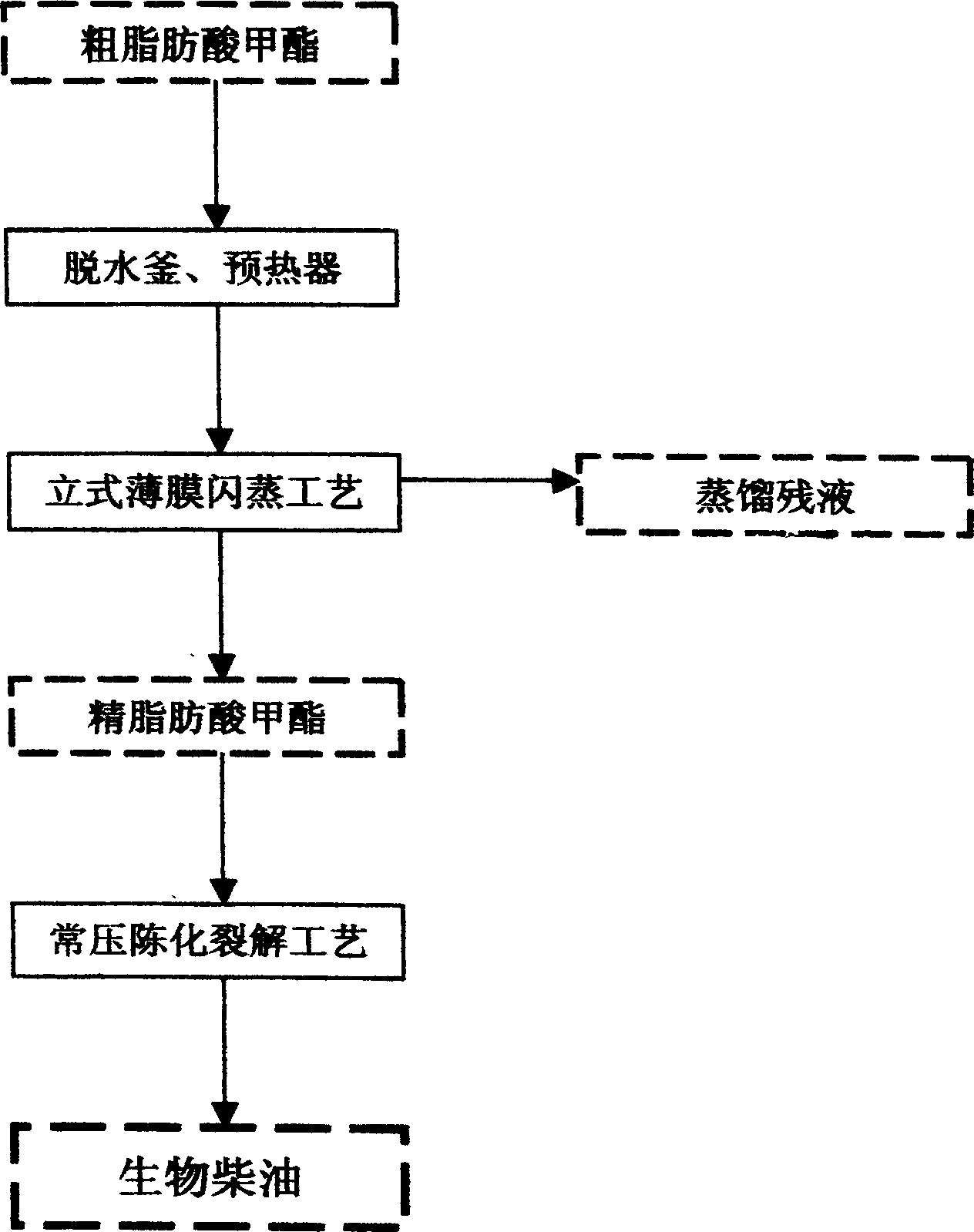

Use of vertical film flash distillation rectifying process in producing bio diesel fuel

A biodiesel and flash distillation technology, which is applied in the field of rectification technology, can solve the problems of low efficiency and large residue generation, and achieve the effects of improving economic benefits, increasing output, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The vertical thin film flash rectification tank designed by the inventor (another patent application of the inventor) is used to rectify the crude methyl ester. There is a tower-shaped thin-film evaporator in the vertical thin-film flash rectification kettle. The jacket around the outer wall of the rectification kettle and the thin-film evaporator are all heat-conducting oil. There is a flow limiter on the top of the tower-shaped thin-film evaporator. There are many small holes around the bottom of the restrictor; the crude methyl ester produced by esterification or transesterification is first dehydrated and preheated through the dehydration kettle and preheater, so that the temperature of the crude methyl ester can reach above 160°C , into the rectification tank at a flow rate of 3500L / h, and the working pressure in the rectification tank is 5mmHg / cm 2 , the crude methyl ester is pulled into the vertical film flash rectification kettle by the vacuum in the kettle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com