Vacuum skull furnace crystallizer and preparation method thereof

A technology of shell condensing furnace and crystallizer, which is applied in foundry equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of overall failure of crucible, low T2 copper strength, crucible deformation, etc., and achieve overall strength improvement, labor efficiency improvement, small deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

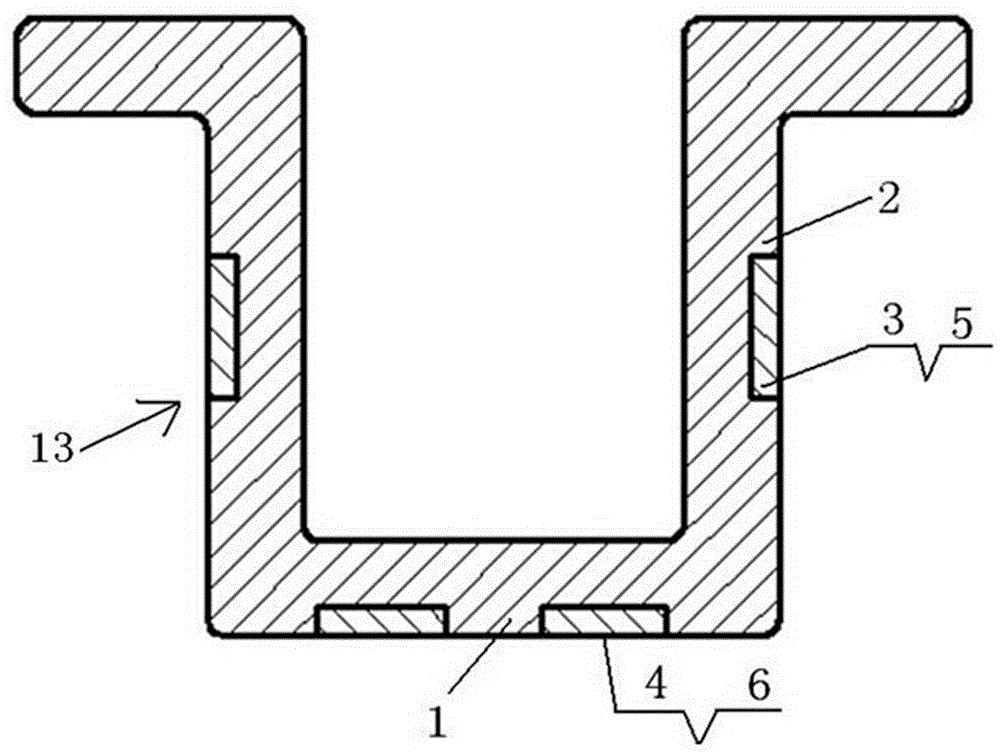

[0021] A vacuum shell solidification furnace crystallizer, comprising a crucible body 13, is characterized in that:

[0022] The waist 2 of the crucible body 13 is provided with a first annular groove 3, the bottom 1 of the crucible body 13 is provided with a second annular groove 4, and a first copper alloy ring 5 is arranged in the first annular groove 3, and Brazed with the crucible body 13 to form an integral structure. A second copper alloy ring 6 is arranged in the second annular groove 4 and brazed with the crucible body 13 to form an integral structure.

Embodiment 2

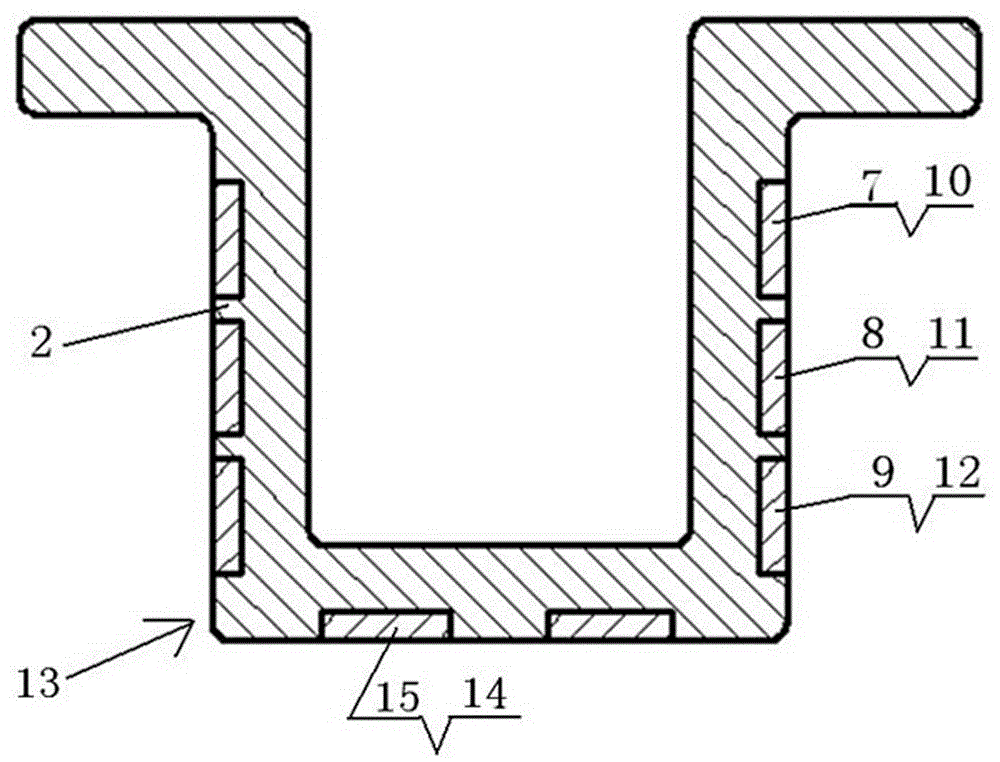

[0024] A vacuum shell solidification furnace crystallizer, comprising a crucible body 13, is characterized in that:

[0025] On the waist 2 of the crucible body 13, a third annular groove 7, a fourth annular groove 8 and a fifth annular groove 9 are opened, and in the third annular groove 7, the fourth annular groove 8 and the fifth annular groove A third copper alloy ring 10 , a fourth copper alloy ring 11 and a fifth copper alloy ring 12 are arranged in the groove 9 respectively, and are brazed with the crucible body 13 to form an integral structure by brazing method. A sixth annular groove 15 is opened on the bottom 1 of the crucible body 13, and a sixth copper alloy ring 14 is arranged in the sixth annular groove 15, and is welded with the crucible body 13 to form an integral structure by brazing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com