Self-adaptive fuzzy control roller variable-speed grinding method

A self-adaptive fuzzy and grinding technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve problems such as large errors and inability to achieve micro-feed intelligent control grinding , to achieve the effect of improving grinding precision, good industrial and social benefits, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

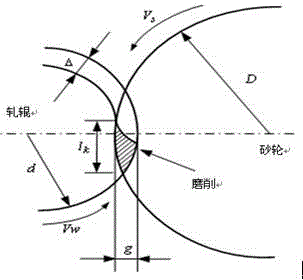

[0009] Such as figure 1 As shown, the roll grinding motion is a special grinding process formed between the CNC roll grinder, the grinding wheel, and the roll. Therefore, in the study of roll grinding mechanism, the influence of roll grinding motion parameters on grinding accuracy is considered based on the grinding geometric relationship.

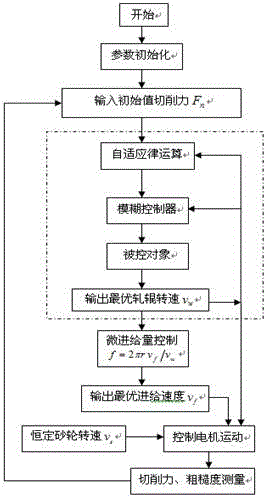

[0010] In constructing adaptive systems (such as figure 2 Under the premise of the dotted line box), the parameters are initialized, and the optimal roll speed is output through the adaptive control system calculation. In the micro-feed formula The optimal feed speed is output under control, so that the motor movement and machine tool work are controlled, and then the cutting force of the grinding wheel and the roughness of the roll are fed back during the processing, and then the optimal output is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com