Sleeve guide groove of automatic assembly system for sleeper sleeve

A technology of automatic assembly and material guide groove, which is applied in the field of sleeper manufacturing, can solve the problems of heavy labor, low work efficiency, waste of manpower, etc., and achieve the effects of improving industrial efficiency, stable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

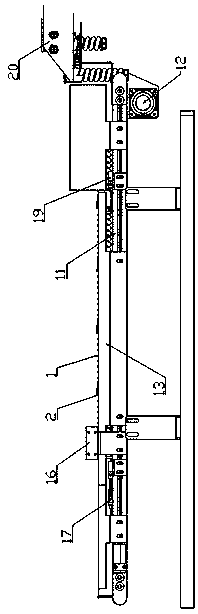

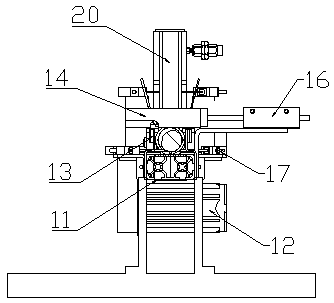

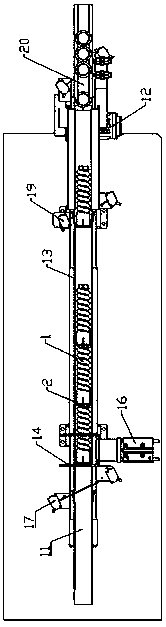

[0015] Such as Figure 1-4 As shown in the figure, there is a bushing guide trough for an automatic assembly system for sleeper bushings. The bushing is a threaded pipe 1, and one end of the threaded pipe 1 is provided with an outer step 2. The feed trough includes a conveyor belt 11 and a driving conveyor belt 11. The driving motor 12 for transmission, the two sides of the conveyor belt 11 are respectively provided with side plates 13, and a sleeve transmission channel is formed between the side plates 13, and the sleeves are intermittently output from the feeding device 20 and laterally input from the inlet end of the transmission channel; the side plates 13 The height is greater than the outer diameter of the threaded pipe 1 and smaller than the outer diameter of the outer step 2. The upper end of the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com