Aluminum alloy for high-speed train axle box and manufacturing method of high-speed train axle box

A manufacturing method and high-speed train technology, applied in the field of aluminum alloy materials, can solve the problems that the performance is difficult to meet the high requirements of high-speed train axle boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

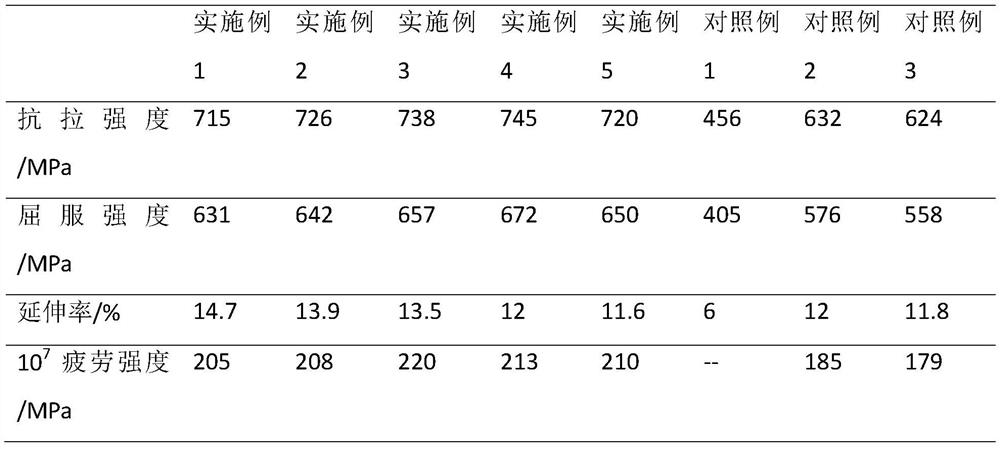

Examples

Embodiment 1

[0027] The aluminum alloy for high-speed train axle box body of this embodiment, its chemical element composition mass percentage content includes: 5.8% Zn, 1.5% Mg, 2.0% Cu, 0.1% Zr, 0.07% Ti, the rest is Al. Among them, it is made of the following raw materials: Al-Cu master alloy, Al-Zr master alloy, Al-Ti master alloy, pure Al, pure Zn and pure Mg.

[0028] The manufacturing method of the high-speed train axle box body of the present embodiment adopts the aluminum alloy for the high-speed train axle box body described above, comprising the following steps:

[0029] (1) After the above-mentioned pure Al is heated until it is completely melted, the temperature of the melt is raised to 680°C, and an Al-Cu master alloy is added; then the temperature of the melt is raised to 7200°C, and an Al-Zr master alloy and an Al-Ti master alloy are added; Then the melt was cooled to 690°C, and pure Zn and pure Mg were added; finally, the melt was heated to 720°C, stirred for 2 minutes, an...

Embodiment 2

[0038] The aluminum alloy for high-speed train axle box body of this embodiment, its chemical element composition mass percentage content includes: 6.1% Zn, 1.6% Mg, 2.2% Cu, 0.13% Zr, 0.08% Ti, the rest is Al. Among them, it is made of the following raw materials: Al-Cu master alloy, Al-Zr master alloy, Al-Ti master alloy, pure Al, pure Zn and pure Mg.

[0039] The manufacturing method of the high-speed train axle box body of the present embodiment adopts the aluminum alloy for the high-speed train axle box body described above, comprising the following steps:

[0040] (1) After the above-mentioned pure Al is heated until it is completely melted, the temperature of the melt is raised to 685° C., and an Al-Cu master alloy is added; the temperature of the melt is raised to 725° C., and an Al-Zr master alloy and an Al-Ti master alloy are added; Then the melt was cooled to 695°C, and pure Zn and pure Mg were added; finally, the melt was heated to 725°C, stirred for 2 minutes, and...

Embodiment 3

[0049] The aluminum alloy for the high-speed train axle box body of this embodiment has the composition of chemical elements in mass percent: 6.2% Zn, 1.71% Mg, 2.37% Cu, 0.15% Zr, 0.08% Ti, and the rest is Al. Among them, it is made of the following raw materials: Al-Cu master alloy, Al-Zr master alloy, Al-Ti master alloy, pure Al, pure Zn and pure Mg.

[0050] The manufacturing method of the high-speed train axle box body of the present embodiment adopts the aluminum alloy for the high-speed train axle box body described above, comprising the following steps:

[0051] (1) After the above-mentioned pure Al is heated until it is completely melted, the temperature of the melt is raised to 690°C, and an Al-Cu master alloy is added; then the temperature of the melt is raised to 730°C, and an Al-Zr master alloy and an Al-Ti master alloy are added; Then the melt was cooled to 700°C, and pure Zn and pure Mg were added; finally, the melt was heated to 725°C, stirred for 3 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com