Patents

Literature

48 results about "Transverse frictions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

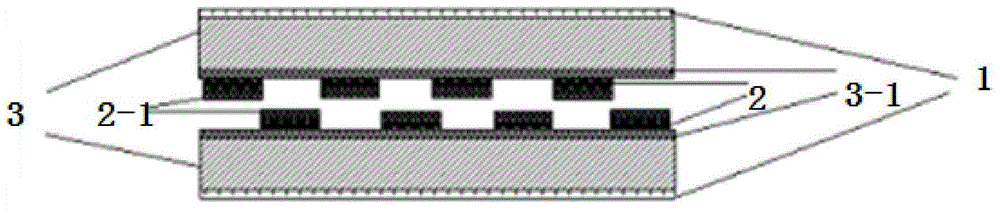

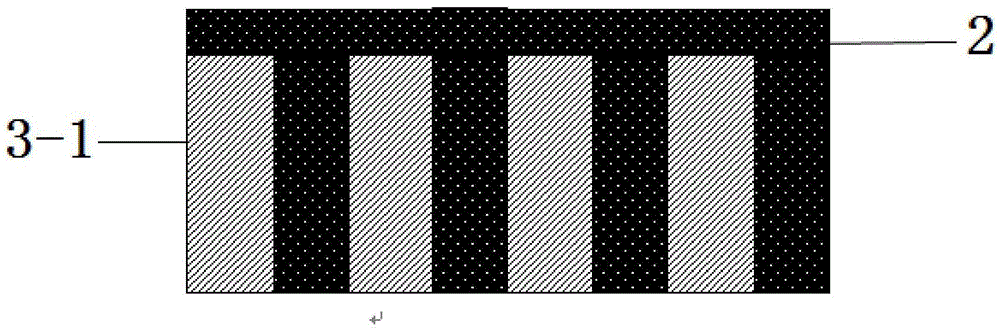

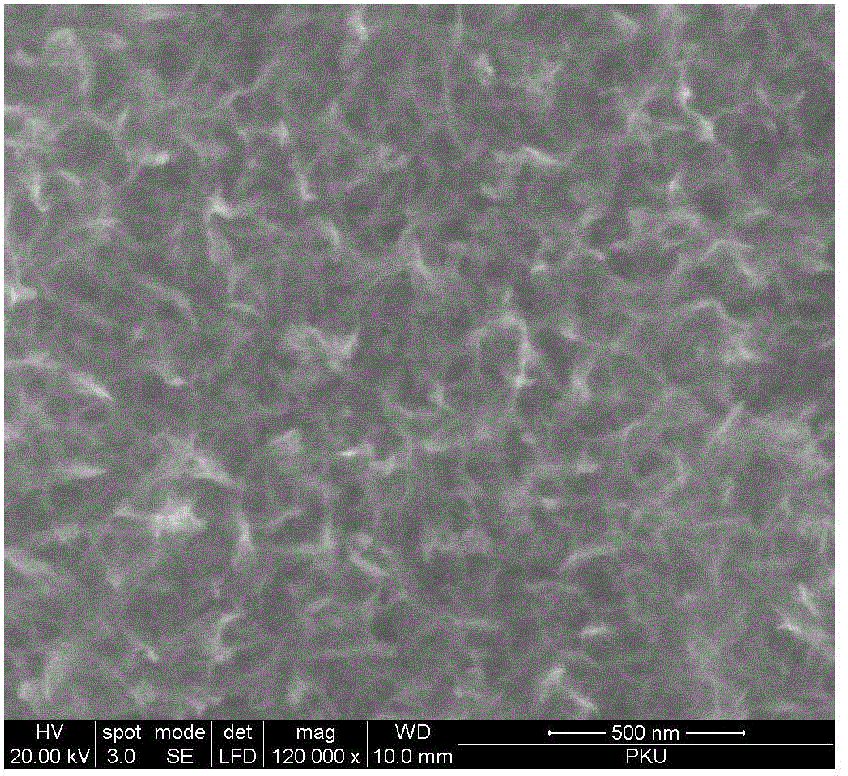

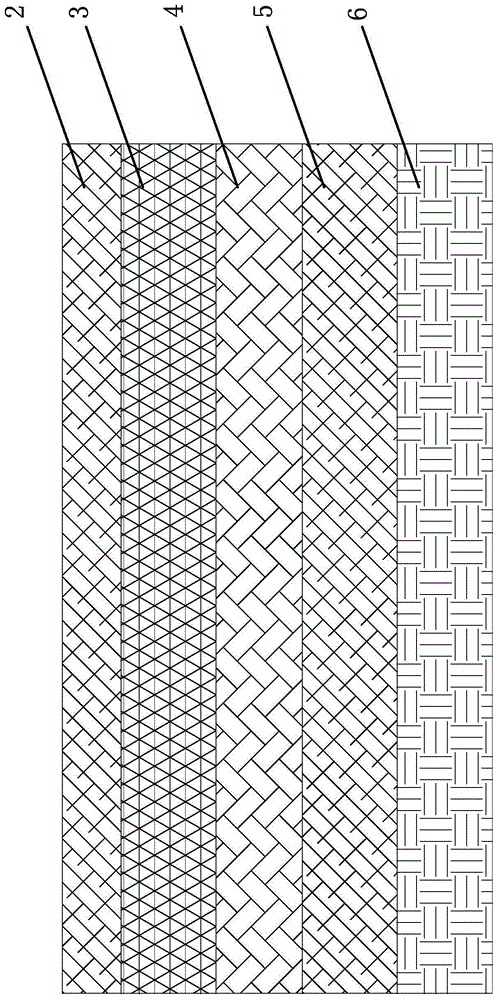

Single-surface friction power generator based on transverse friction and preparation method of single-surface friction power generator

InactiveCN103337985ASimple processLow costDecorative surface effectsChemical vapor deposition coatingNano structuringNanogenerator

The invention relates to the technical field of MEMS (Micro-electro-mechanical System) integration processing, in particular to a single-surface friction power generator based on transverse friction and a preparation method of the single-surface friction power generator. The single-surface friction power generator is formed in a manner that two identical structures are arranged in a relatively and mutually horizontal friction manner, wherein each structure comprises five layers; conducting layers are arranged at the outermost layers; thin film layers are adjacent to the conducting layers; thin film nano structure layers are arranged on the other sides of the thin film layers; metal electrodes are arranged on the other sides of the thin film nano structure layers; and metal electrode nano structure layers are arranged on the other sides of the metal electrodes. The single-surface friction power generator has the advantages that compared with the traditional two-layer thin film power generator in a vertical direction, the single-layer structure uses friction in a horizontal direction, and electrode outputs are in the same plane, so that subsequent processing and integration are facilitated; the nano power generator and the preparation method thereof are simple in technology, low in cost, high in productivity, and easy to integrate and process; mass production is available; and the novel structure effectively uses the friction in the horizontal direction in nature.

Owner:PEKING UNIV

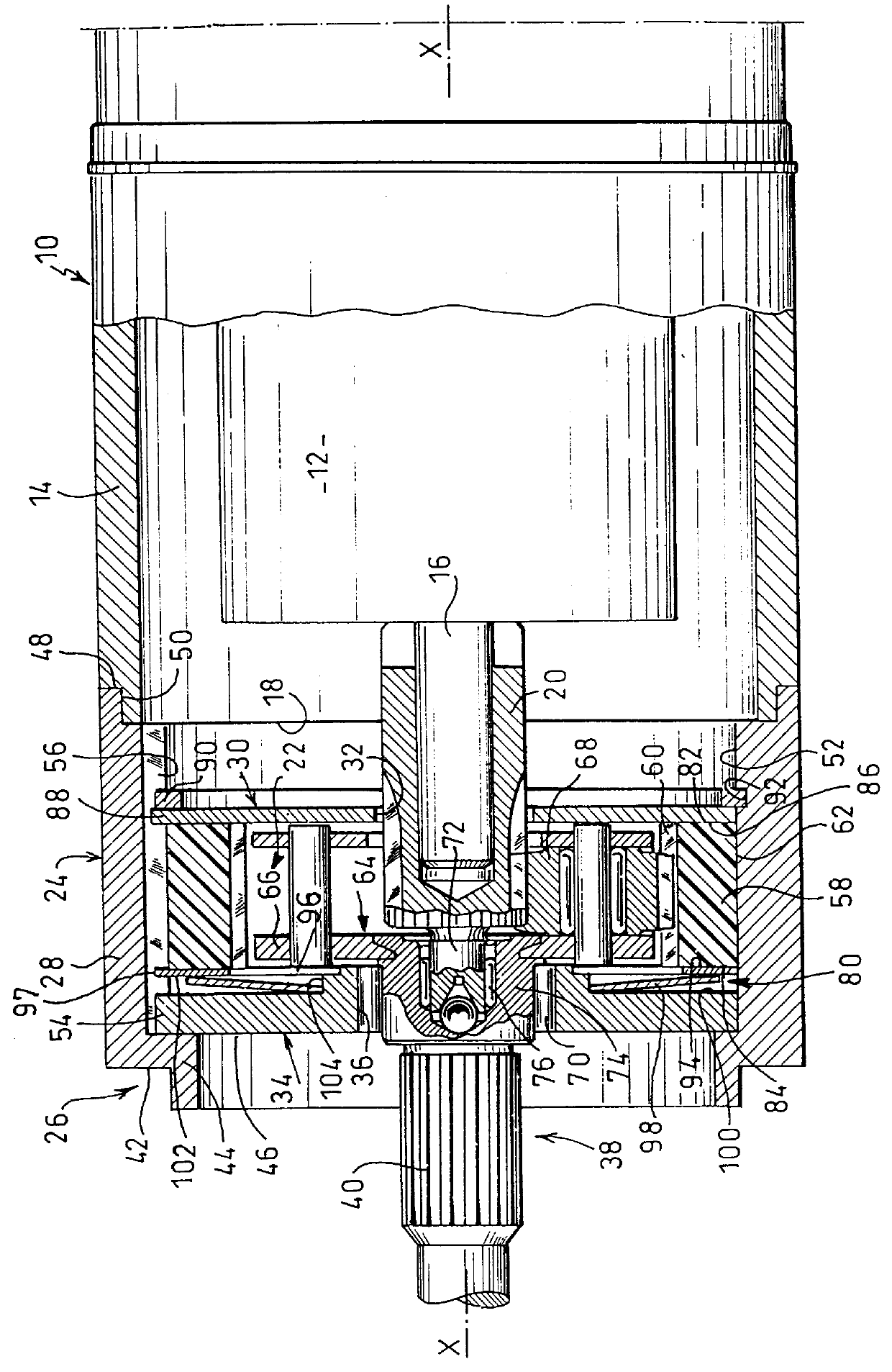

Motor vehicle starter with an epicyclic reducing gear train including a torque limiting device

InactiveUS6076413AGood friction propertiesImprove wear resistancePower operated startersSlip couplingTransverse frictionsGear wheel

A starter for a motor vehicle comprises an electric motor having an output shaft which drives a coaxial starter head through a speed reducer. The speed reducer incorporates an epicyclic gear train, including a cylindrical casing within which the internally toothed crown wheel of the epicyclic gear train is mounted in rotation. The crown wheel is coupled in rotation to the casing through a friction type torque limiting device, which is interposed axially between the crown wheel and a transverse plate of the casing. The torque limiting device includes at least one annular transverse friction surface of the crown wheel, which is biased elastically into axial engagement against a reaction surface coupled in rotation to the casing.

Owner:VALEO EQUIP ELECTRIC MOTEUR

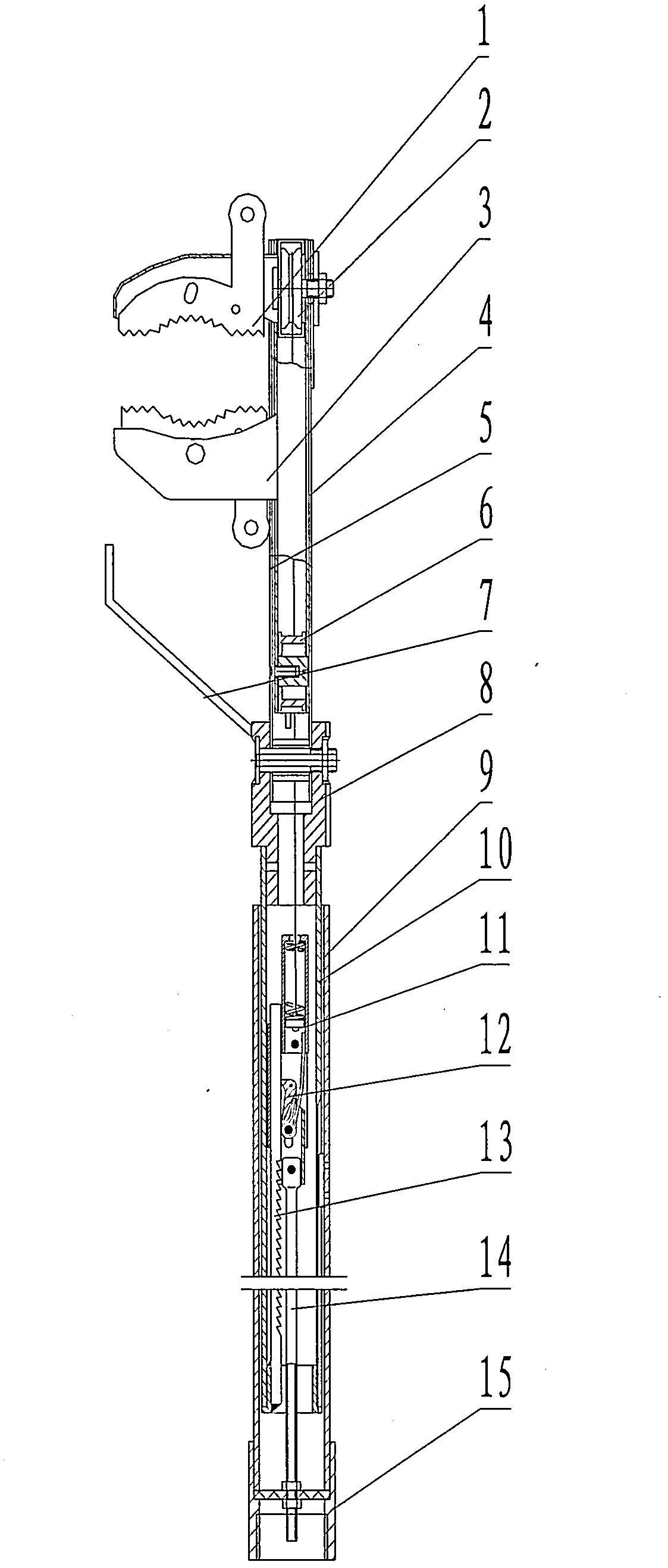

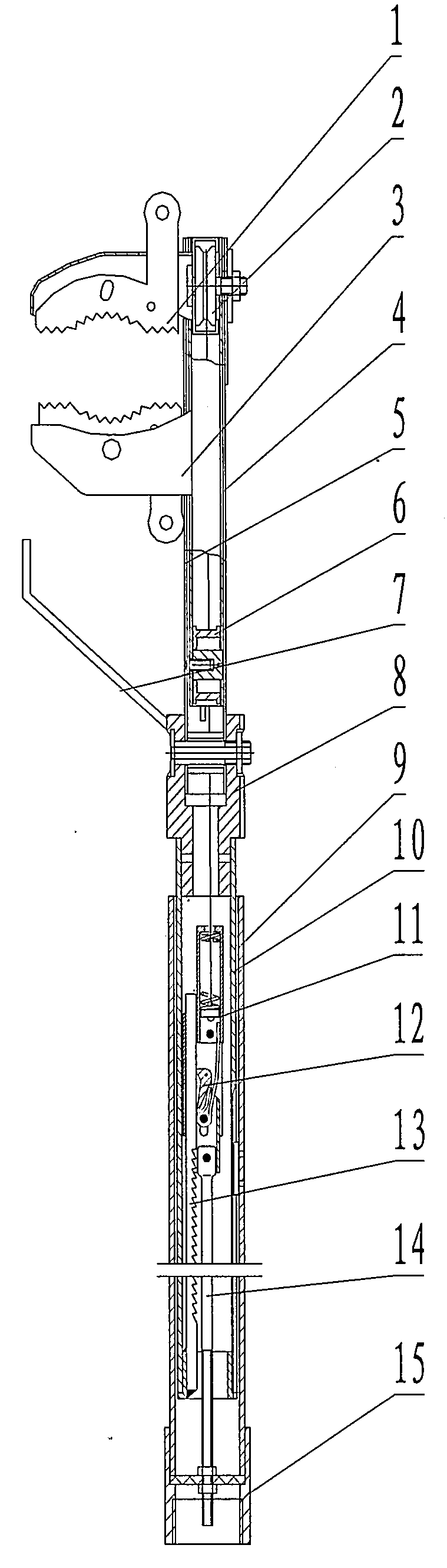

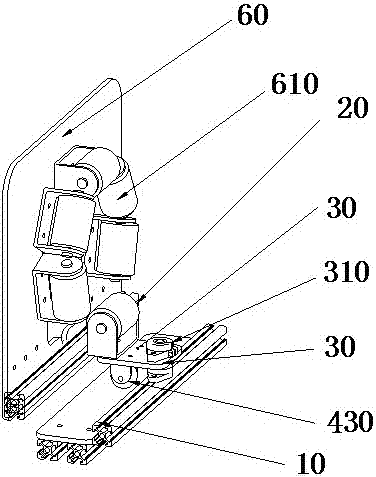

Multi-angle operating rod

InactiveCN102510028AImprove working conditionsAvoid dangerApparatus for overhead lines/cablesLocking mechanismTransverse frictions

The invention relates to an insulated operating rod, and is particularly applicable to temporary wiring for test and maintenance to a high-altitude device and operated on the ground. At present, high-altitude test wiring for the maintenance and the test to a power transmission device is relatively difficult, and certain unsafe factors affect the device and operators. The multi-angle operating rod provided by the invention is composed of a wiring clamp, a specific push-pull rod and a fixed bracket; the wiring clamp consists of an upper clamp jaw and a lower clamp jaw, and the lower clamp jaw moves along pulleys; a steel wire rope connecting an upper pulley and a lower pulley is controlled by a specific push-pull mechanism operated by lifting a long rod; the specific push-pull mechanism is provided with a locking mechanism capable of ensuring a clamping force of the clamp jaw; a mounting hole located between the upper clamp jaw and the lower clamp jaw is long and sloping, and enables the clamp jaws to be tightly clamped and generate transverse friction movement at the same time, thereby overcoming an oxidation film at a wiring position. The invention enables the conventional high-altitude working to be completed on the ground, fundamentally avoids danger caused by climbing, and greatly improves working conditions for the field operators.

Owner:STATE GRID CORP OF CHINA +1

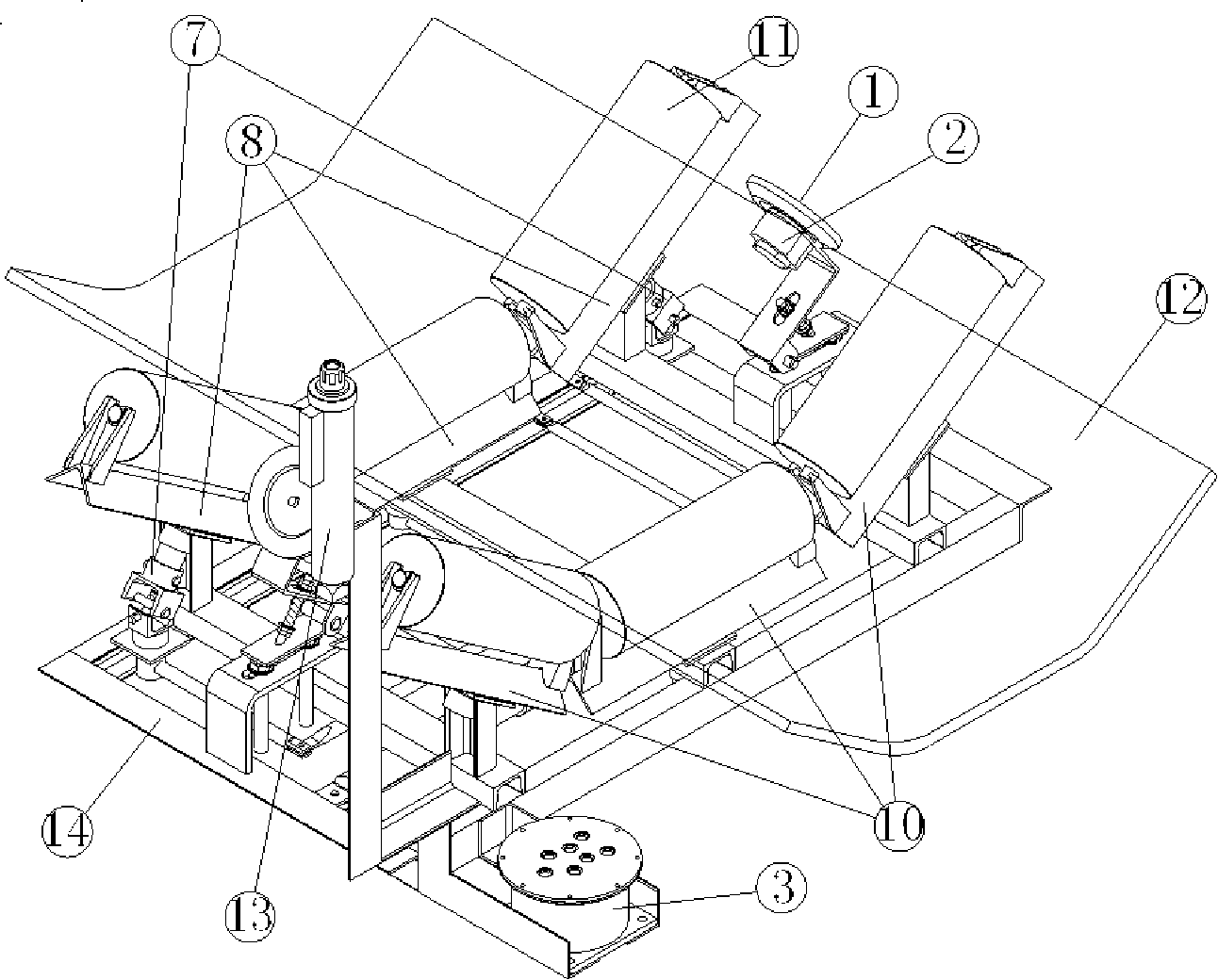

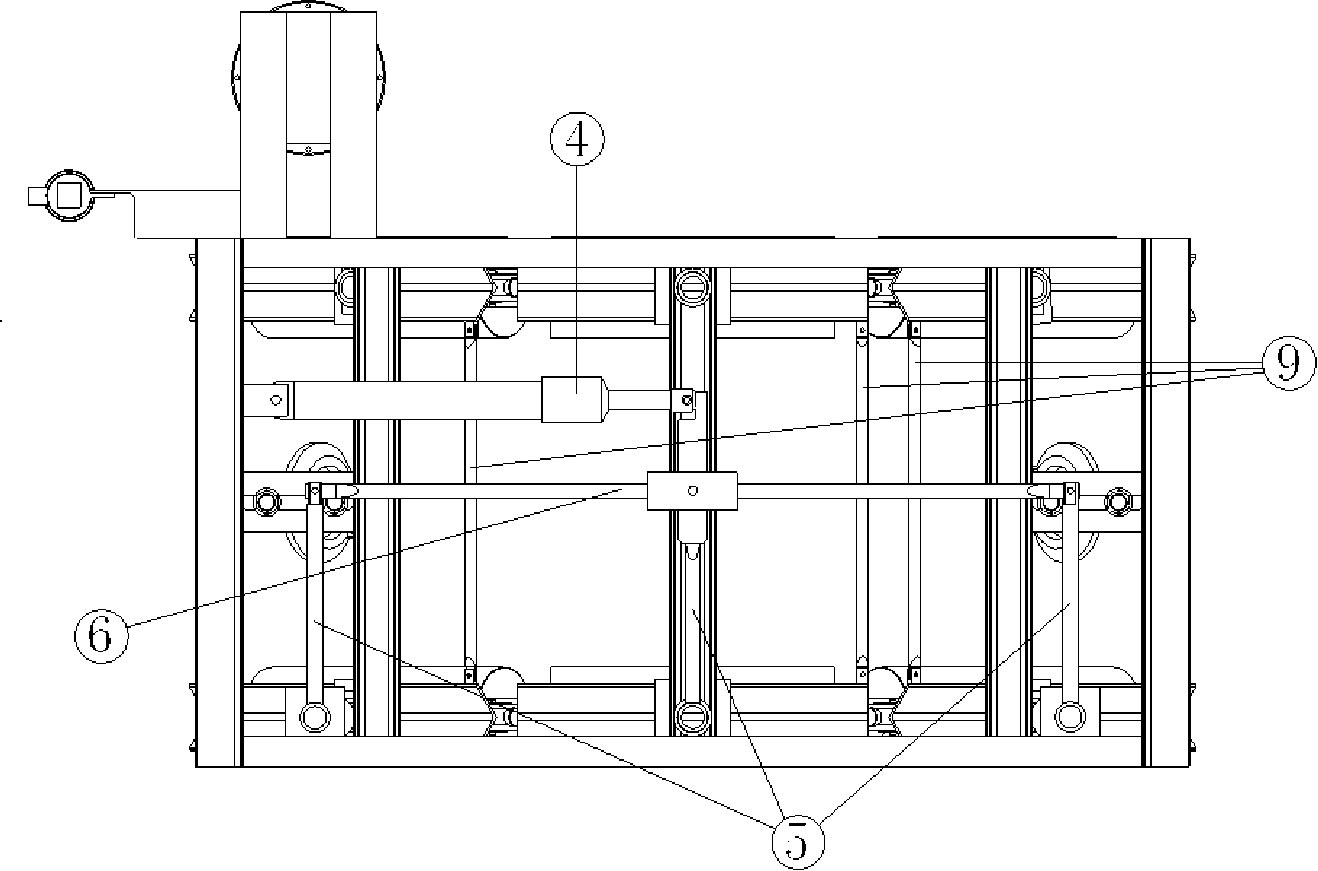

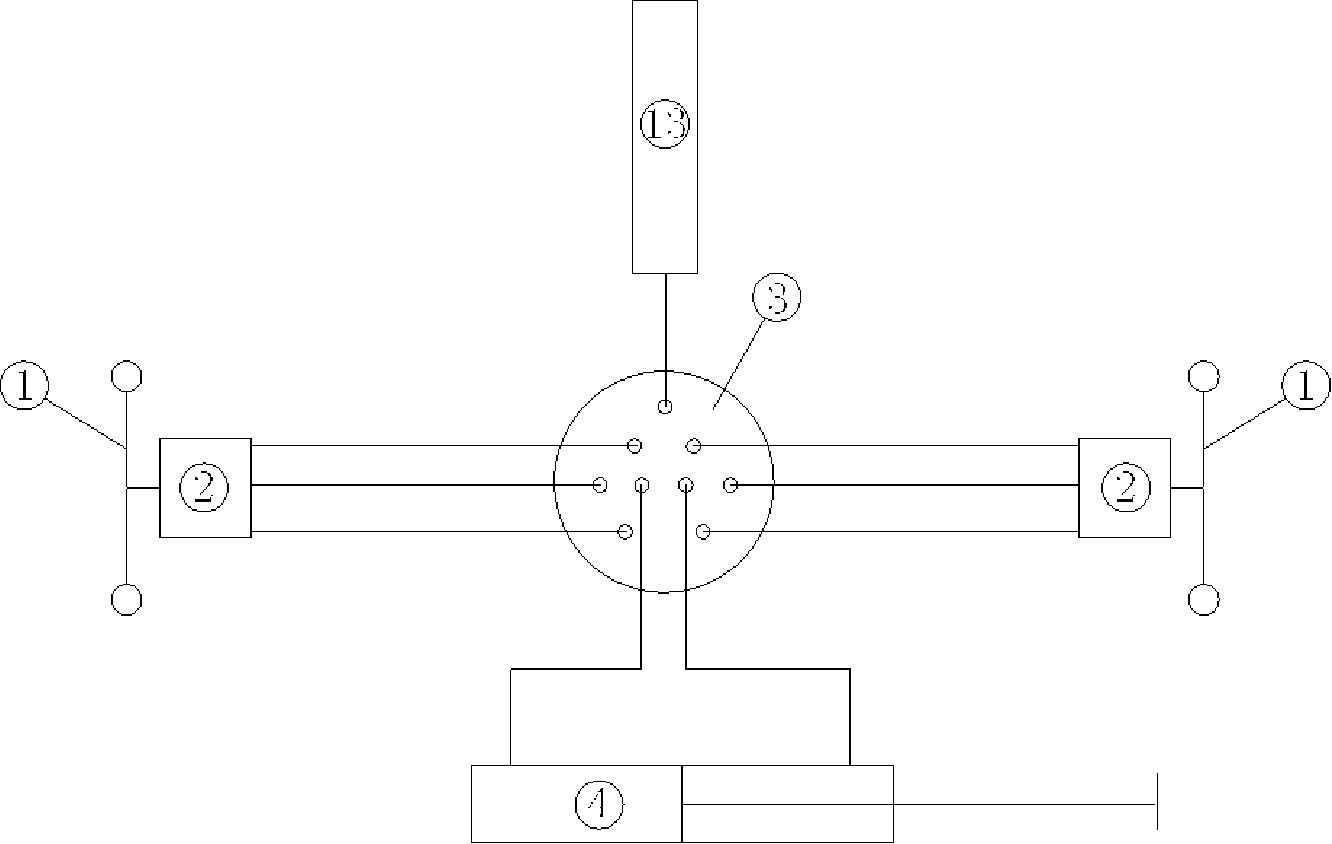

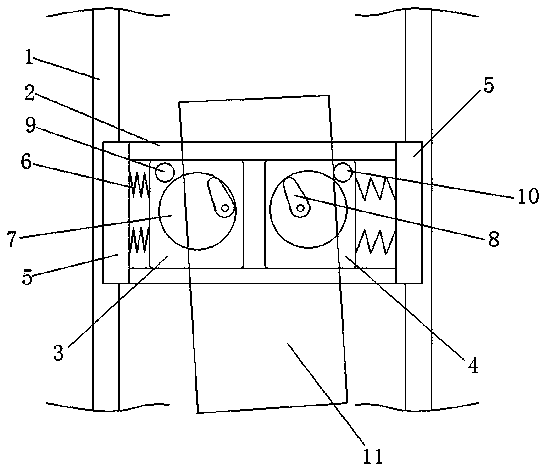

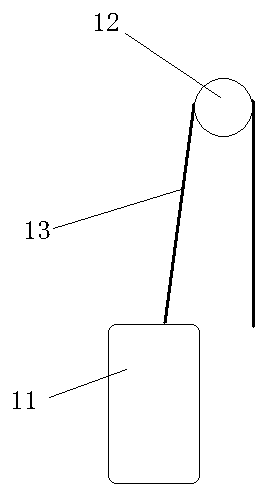

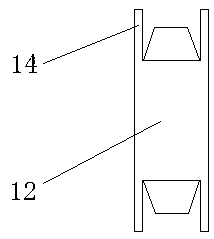

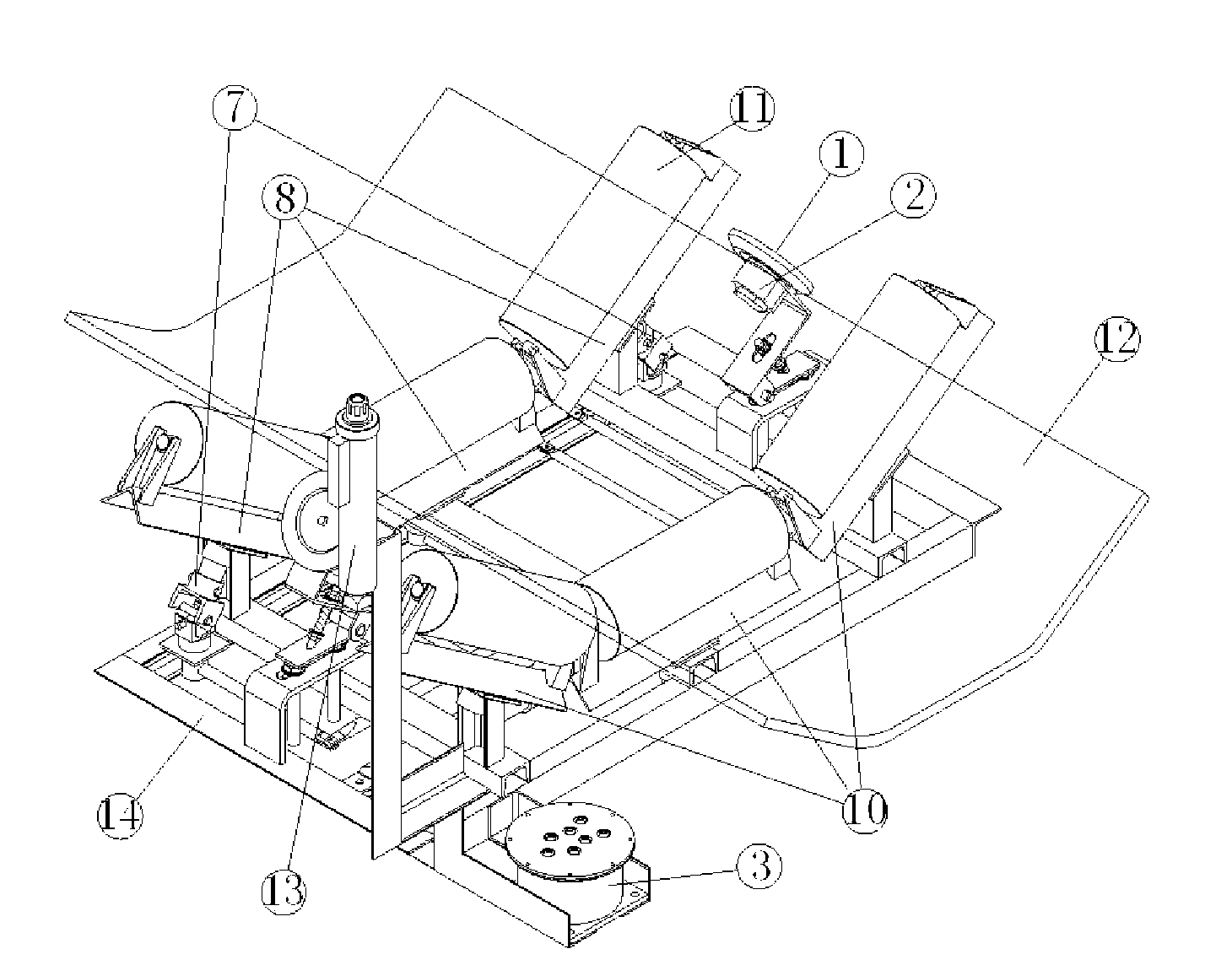

Passive hydraulic control linked error correcting machine

A passive hydraulic control linkage rectification machine which can rectify and prevent the run deviation of a conveyor belt consists of a hydraulic control detecting and driving system and a linkage rectification mechanism. The hydraulic control detecting and driving system consists of a detecting and driving wheel, an oil pump, a cylinder, a midpoint controlling station, a temperature controller and an oil pipe. The linkage rectification mechanism consists of discrete rollers, roller racks, a universal joint, an arm rod, a connecting rod, a pin and a frame. The hydraulic control detecting and driving system is used to detect the run deviation of the belt and simultaneously supplies power for driving the roller racks to deflect. When the belt runs deviated, the belt drives the detecting and driving wheel to rotate. The detecting and driving wheel drives the oil pump to strike the oil pressure to the midpoint controlling station. A logistic valve group of the midpoint controlling station controls the piston rod of the cylinder (4) to push or pull. The piston rod drives the linkage rectification mechanism to lead the roller (11) on the mechanism to deflect synchronously in the same direction. An angle is formed between the linear moving direction of the roller after the deflection and the moving direction of the belt, and the transverse friction of the belt generating during the above process drives the belt to run in the middle. The passive hydraulic control linkage rectification machine requires no power and hydraulic function and has the advantages of synchronous linkage, self-defecting, self-driving and self-system.

Owner:林刚

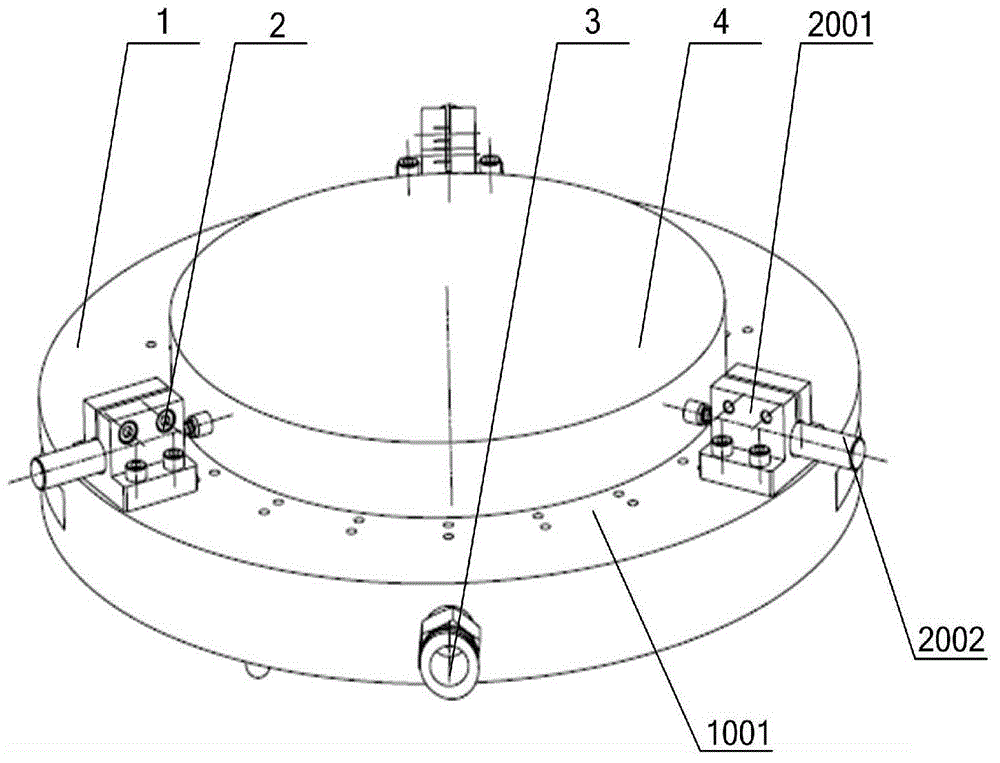

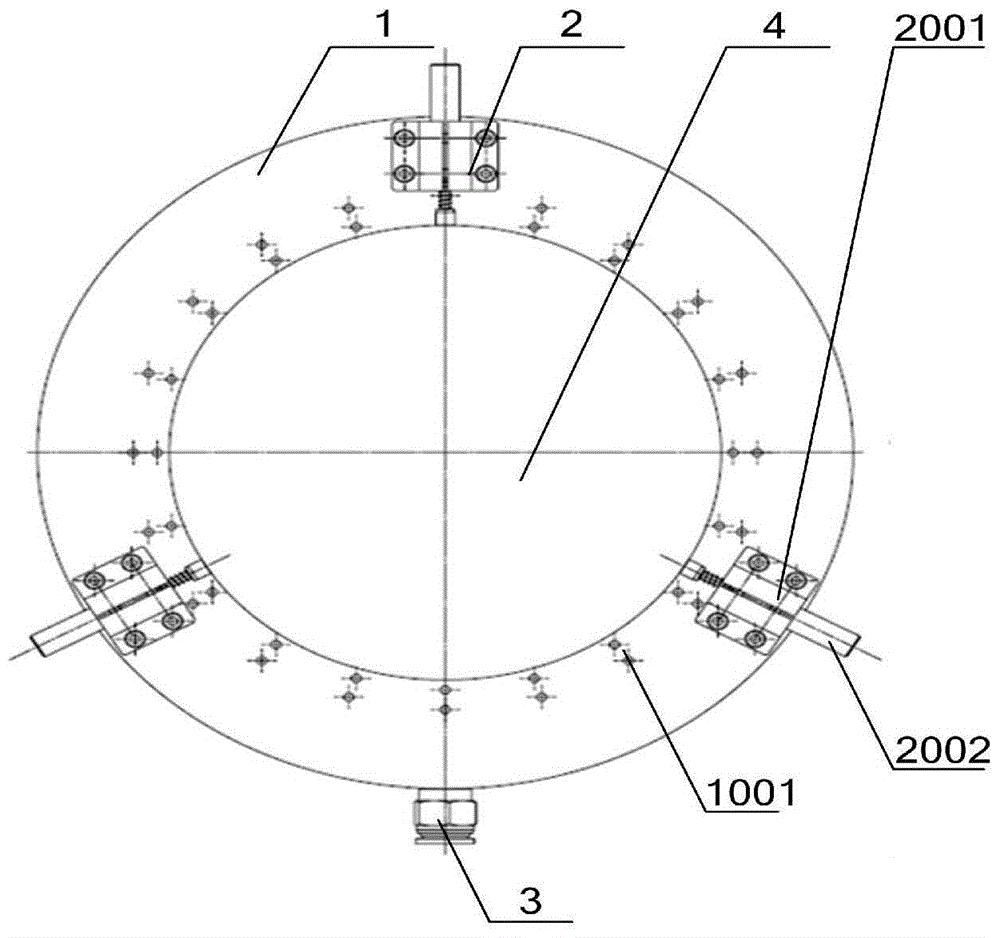

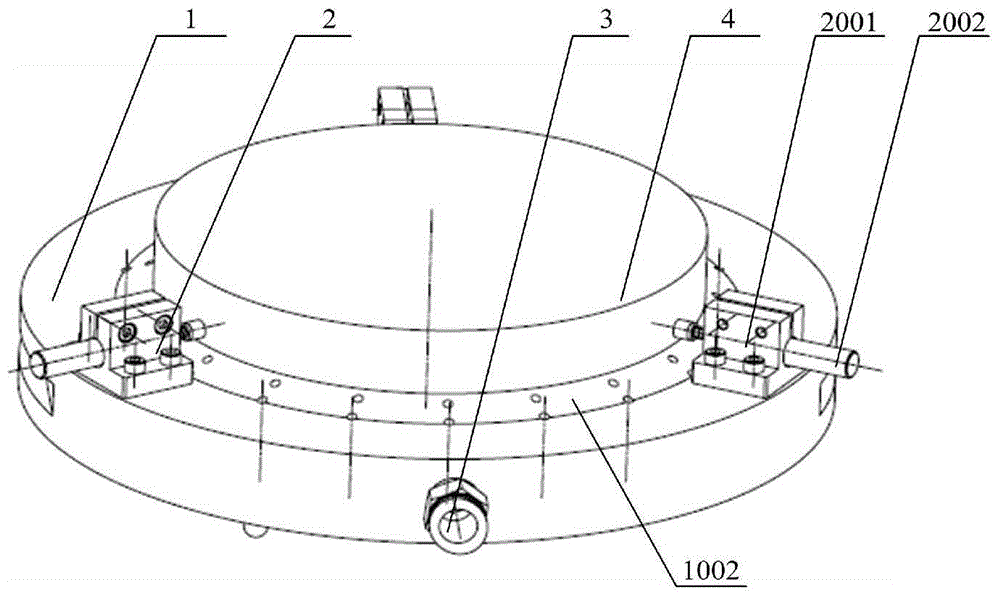

Air flotation high-precision detection tool

InactiveCN104457578AThe principle is simpleComplex structureUsing optical meansTransverse frictionsEngineering

The invention provides an air flotation high-precision detection tool and belongs to the field of optical detection. The detection tool solves the technical problems that due to stress and friction caused by a supporting mode of a traditional detection tool in the prior art, deformation is caused, and precision is low. The detection tool comprises a plane base. A plurality of air injection holes are distributed in the surface of the base. Three limiting blocks are arranged around the base to ensure that the detection work-piece position is fixed. The air flotation principle is utilized, a method of injecting air through the small holes is adopted, an air gap is formed between a detection work-piece and a supporting rigid body, and therefore the work-piece can float above the detection tool to be detected; as an air flotation mode is adopted, the work-piece is stressed uniformly and stably, the transverse friction is avoided, the deformation of the detection work-piece and the stress caused by the transverse friction due to supporting of the tool can be eliminated, the detection reproducibility and the detection precision are improved, and the detection tool can be applied to ultra-high-precision element face shape detection.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

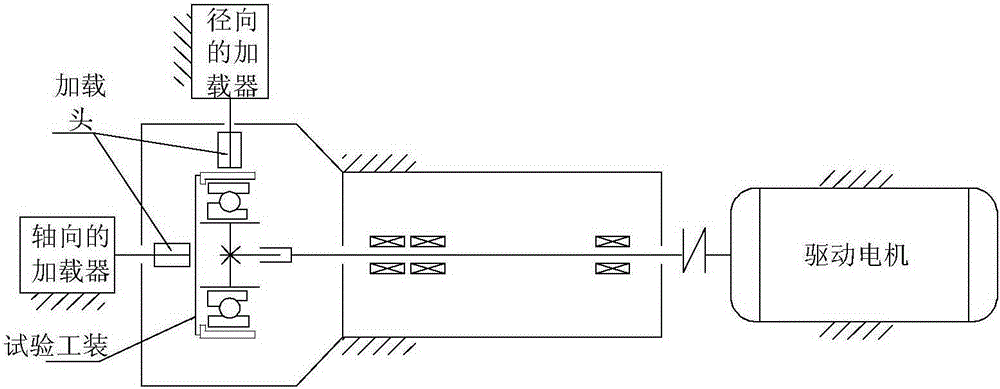

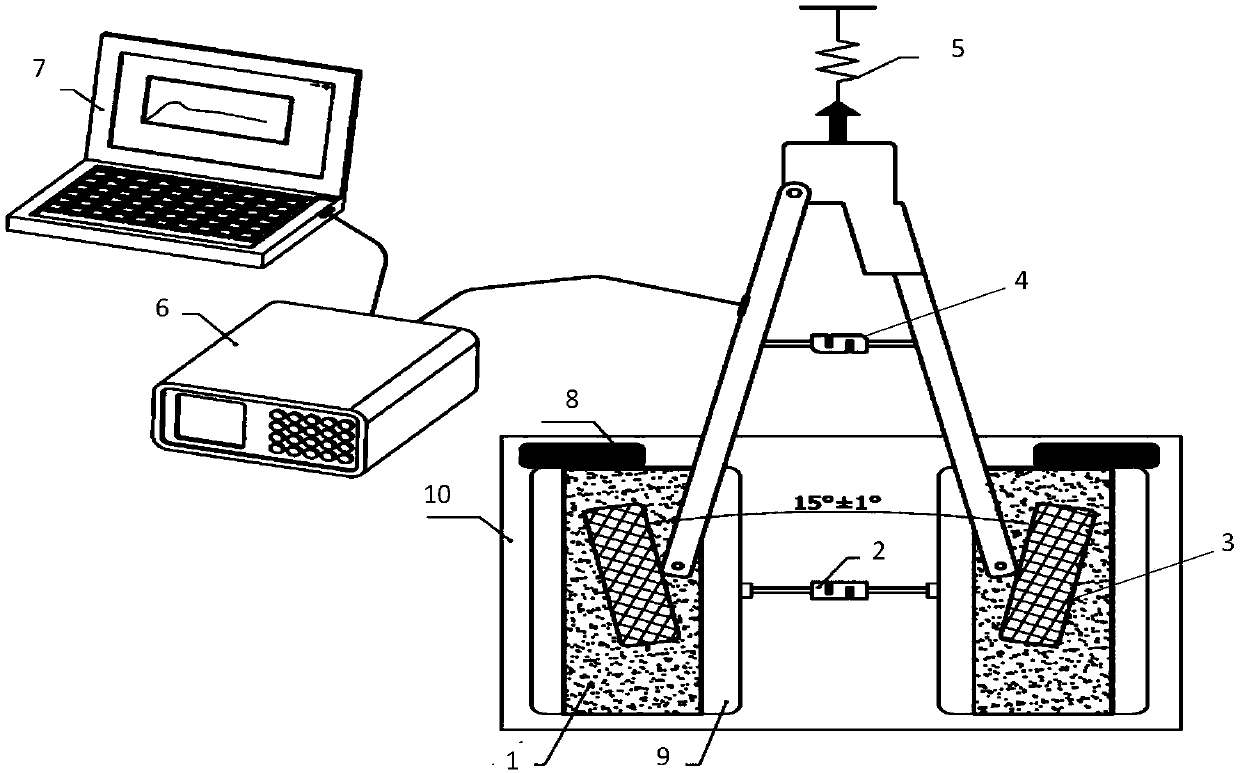

Device and method for measuring transient sliding friction coefficient based on fiber grating

ActiveCN106353249AAddress cross-sensitivity issuesUsing mechanical meansMaterial analysisGratingMeasurement device

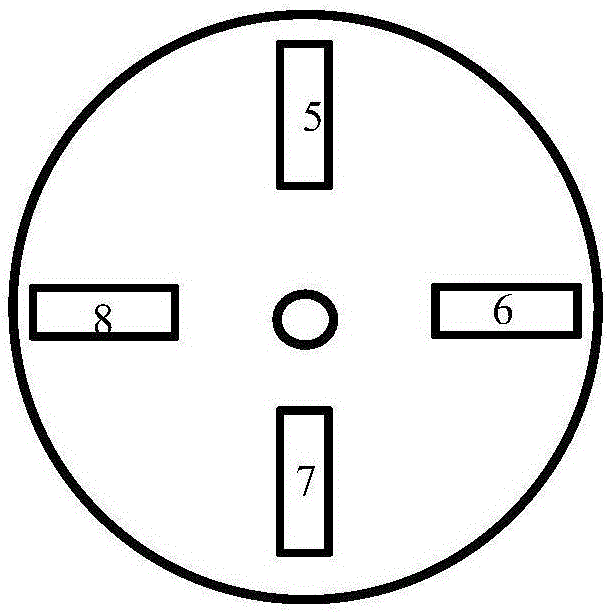

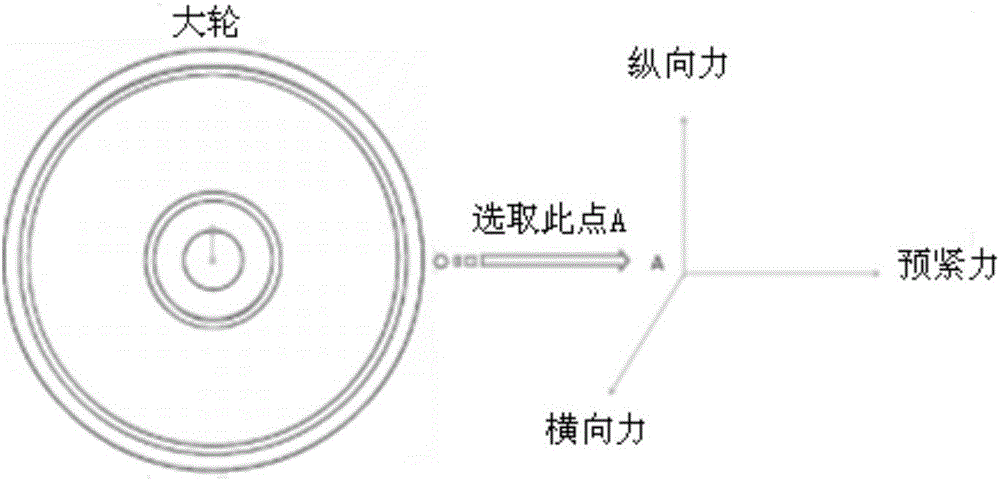

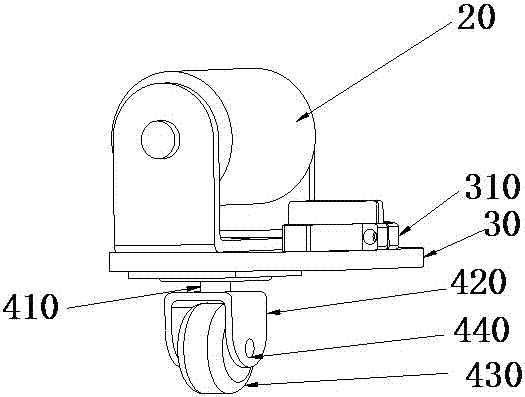

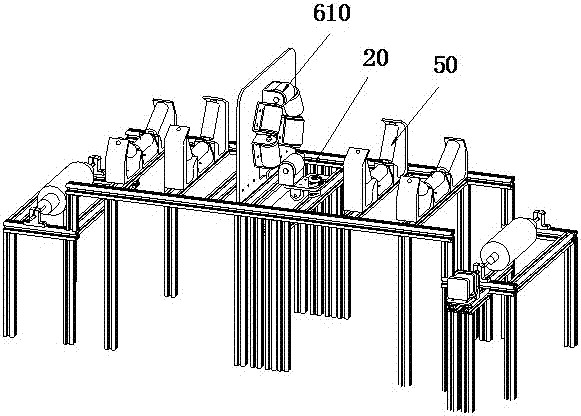

The invention provides a device and a method for measuring a transient sliding friction coefficient based on fiber gratings. The device comprises a small wheel assembling mechanism, a large wheel assembling mechanism, a demodulator and an industrial personal computer; fiber gratings are respectively and symmetrically arranged on front and back surfaces of two supports on the two sides of a small wheel and front and rear sides of a steering wheel; an incidence angle regulator is further installed on a supporting plate; a central plane of a large wheel of the large wheel assembling mechanism and a central plate of the small wheel are on the plane, and wheel sides are tangent; a light source built in the demodulator is transmitted to each of the fiber gratings through a rotary connector, contact points between the large wheel and the small wheel produce a friction force with the rotation of the large wheel, the friction force is transmitted to each of the fiber gratings and the fiber gratings generate strain signals; the demodulator demodulates the strain signals of the fiber gratings and sends demodulated signals to the industrial personal computer; the industrial personal computer receives the demodulator signals, performs acquisition and analysis, calculates transient positive pressure and friction force of the small wheel according to the wavelength shift of the fiber gratings, and calculates a transient transverse friction coefficient at the contact points through a corresponding formula.

Owner:WUHAN UNIV OF TECH

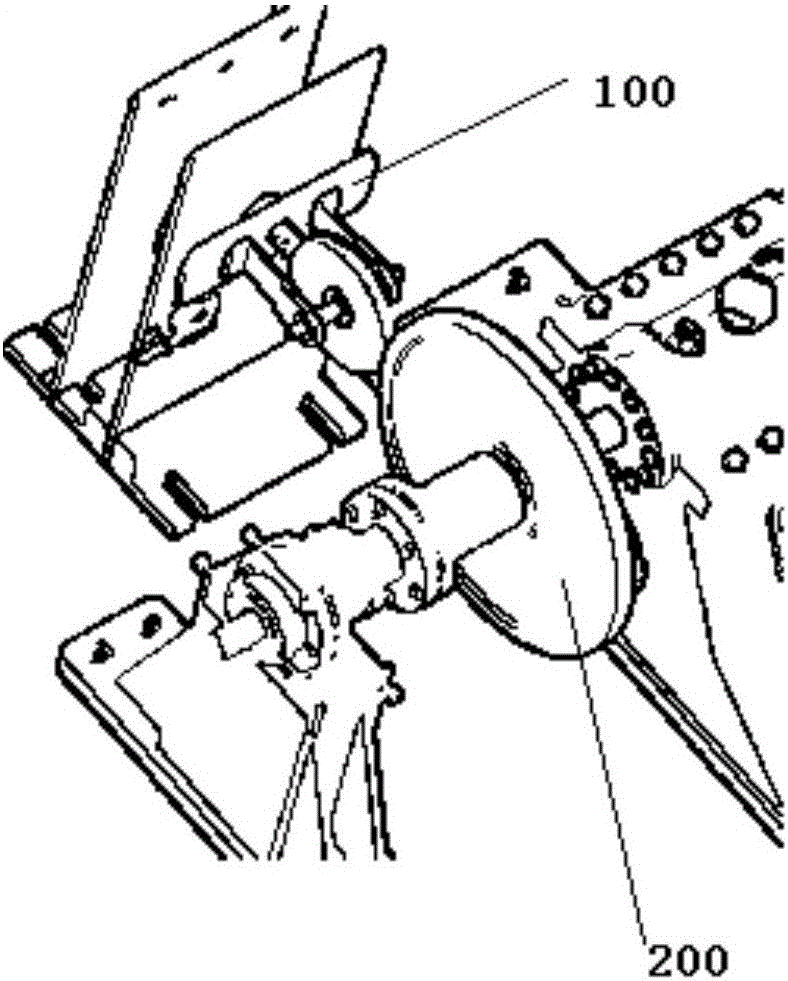

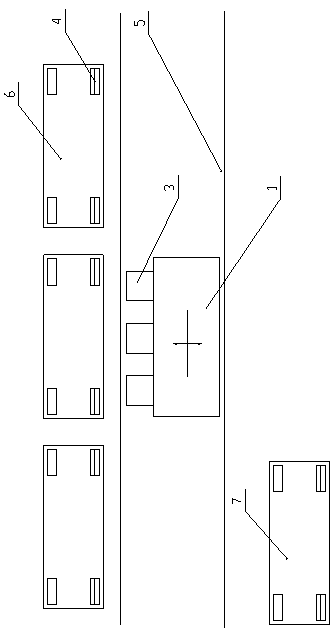

Wind tunnel test section replacement method

ActiveCN108896267ASolve shipping problemsSolve replacementAerodynamic testingMode of transportTransverse frictions

The invention discloses a large wind tunnel test section replacement method. The purpose is to solve the problem that according to an existing wind tunnel test section transportation mode, travellingmechanisms turn inconveniently or positioning is not accurate during replacement. According to the large wind tunnel test section replacement method, test section transportation vehicles are adopted for conducting test section transportation and replacement, a test section is not provided with travelling mechanisms, and through lifting, 90-degree turning of wheels and freely parallel operation ofthe multiple vehicles of the test section transportation vehicles, turning of the wind tunnel test section is achieved; meanwhile, a V-flat slideway mode is adopted for positioning wind tunnel test stations of the test section, round liquid hydrostatic bearings are arranged on the test section transportation vehicles and are used for reducing transverse friction force when the test section falls into a slideway, and through cooperation of the V-flat slideway, the wind tunnel test section and the round liquid hydrostatic bearings, the wind tunnel test section is precisely positioned. By means of the large wind tunnel test section replacement method, the problems that during wind tunnel test section transportation and replacement, positioning is not accurate, and the travelling mechanisms need to turn can be effectively solved, so that the large wind tunnel test section replacement method has a high application value.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

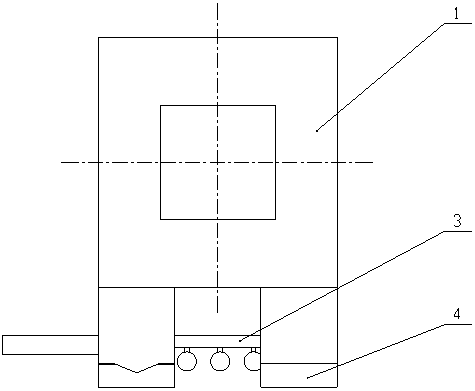

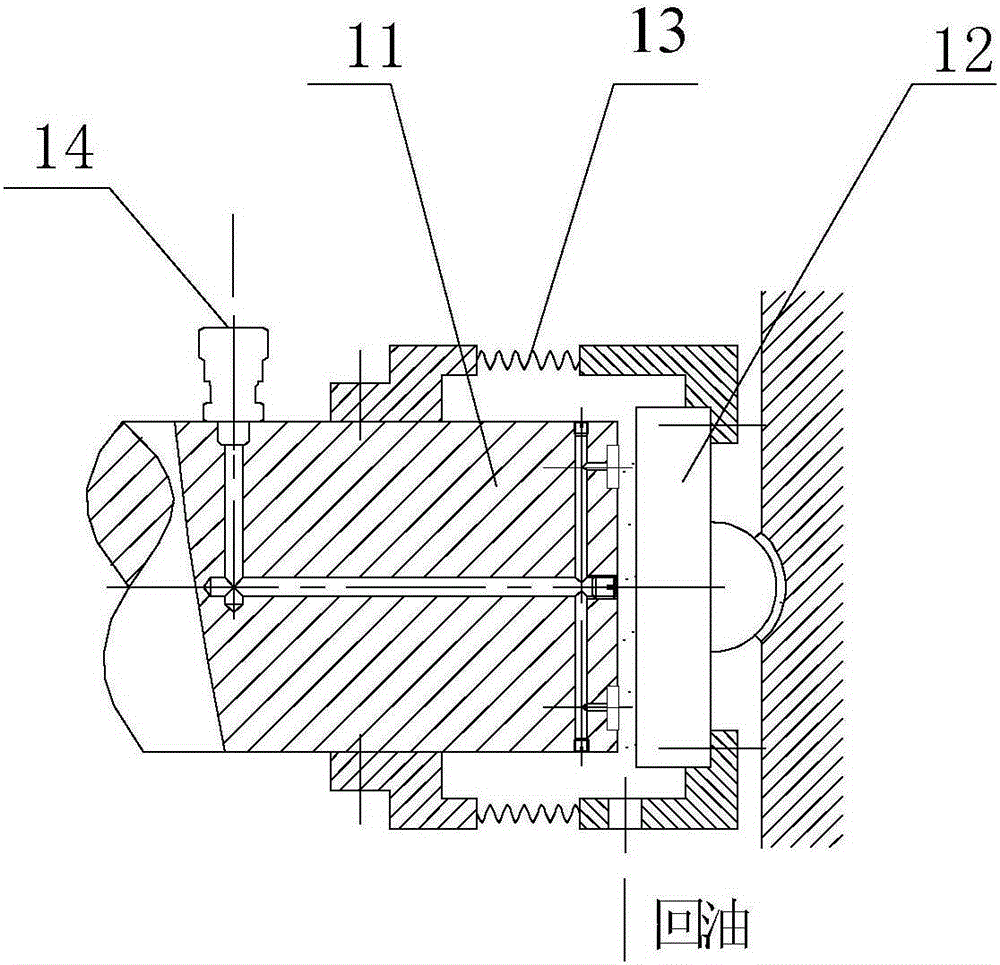

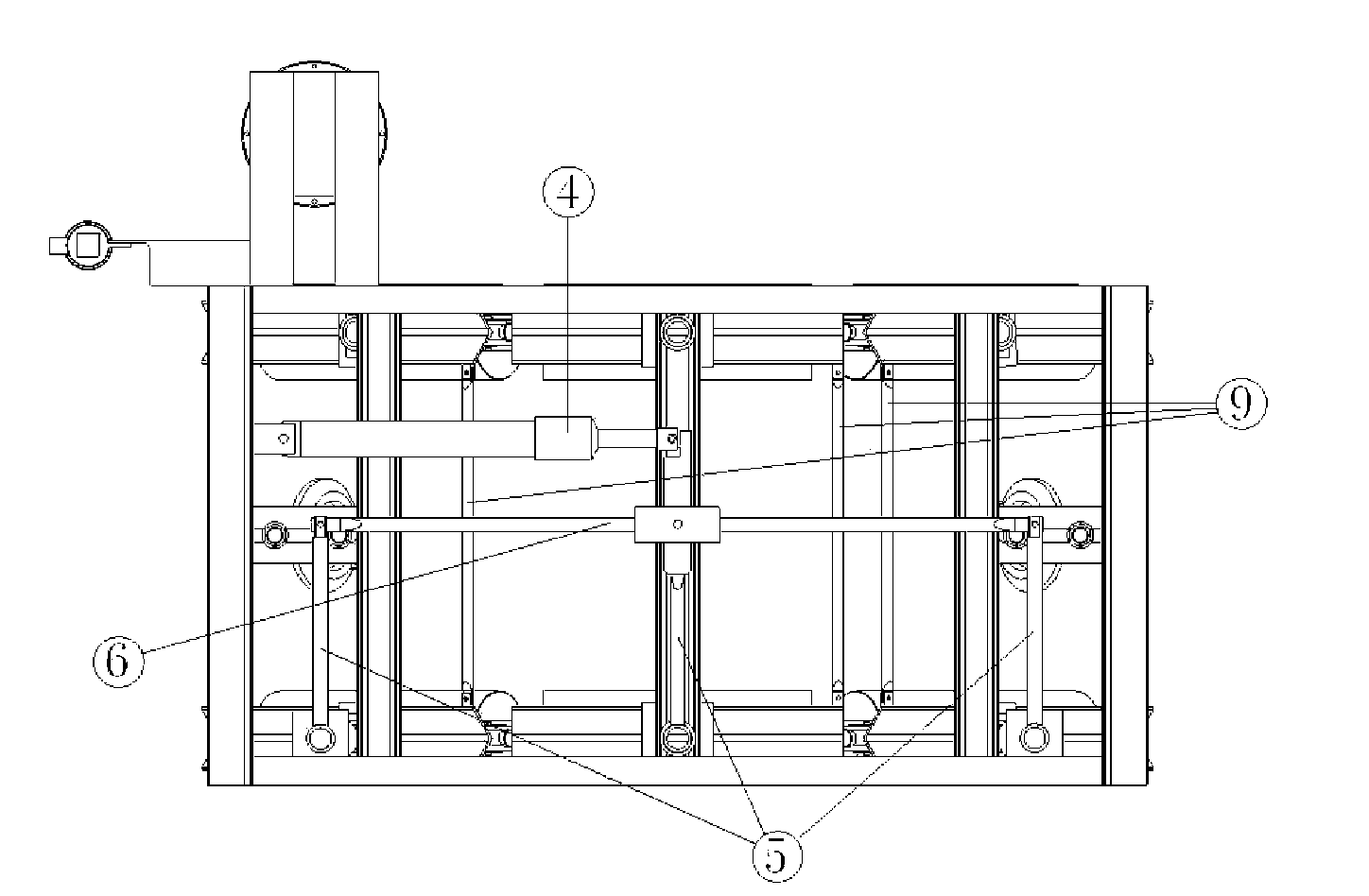

Low-coupling axial and radial combined loading device for rolling bearing and loading method

InactiveCN105157982AGuaranteed pressureAvoid pollutionMachine bearings testingTransverse frictionsRolling-element bearing

The invention discloses a low-coupling axial and radial combined loading device for a rolling bearing and a loading method, and relates to the loading field of bearing tests. The low-coupling axial and radial combined loading device for the rolling bearing and the loading method aim to solve a problem in the prior art that the transverse friction between contact surfaces of the bearing and the load is high after loading when an axial load and a radial load are applied to a tested bearing simultaneously, the transverse stiffness of the loading device is great, the friction between a loading head in one direction and a test assembly restricts movement of a loading head in another direction, application of the load in the other direction is further affected, loads in one or two directions cannot be completely loaded to the tested bearing, and loading of the loads is caused to be inaccurate. According to the invention, a small oil tank is placed below the bearing, a hydraulic pump extracts oil in the small oil tank, then the extracted oil is injected into a pressure oil inlet, a liquid hydrostatic pressure bearing ability is generated after the oil flows through a liquid hydrostatic pressure orifice, a hydraulic moving disc and a hydraulic static disc are connected through an elastic connecting sleeve, and a coupling effect of loads in different directions is reduced. The loading device and the loading method provided by the invention can be applied to a test device which needs to simultaneously apply two loads which are vertical with each other in direction.

Owner:HARBIN INST OF TECH

Belt deflection correcting device

InactiveCN102092562AIncrease bottom spaceCompact structureConveyorsRollersTransverse frictionsEngineering

The invention discloses a belt deflection correcting device. The device comprises supporting legs, a fixing bracket, and an aligning roller, a driving detection device and oil cylinders which are arranged on the fixing bracket, wherein the fixing bracket is a horizontal beam bridged on the supporting legs; the upper parts of the two ends of the fixing bracket are provided with an arc-shaped track respectively; the two arc-shaped tracks are concentric with each other; roller wheels at two ends of the aligning roller are embedded with the arc-shaped tracks; and the two ends of the aligning roller are hinged with oil cylinder piston rods on the fixing bracket. The device has a larger bottom space, a compact structure and greatly improved performance reliability and is convenient to mount. When a belt is deviated toward one side, the side edge of the belt touches the driving detection device and drives an oil pump to work, so that the oil cylinder piston rod on one side is extended, and the oil cylinder piston rod on the other side is retracted at the same time; the oil cylinders on the two sides perform reverse motion synchronously to drive the aligning roller to rotate; and transverse friction force is generated depending on a deflection angle formed between the rotating direction of the aligning roller and the advancing direction of the belt so as to finally realize a deflection correction function.

Owner:山西潞安集团司马煤业有限公司 +1

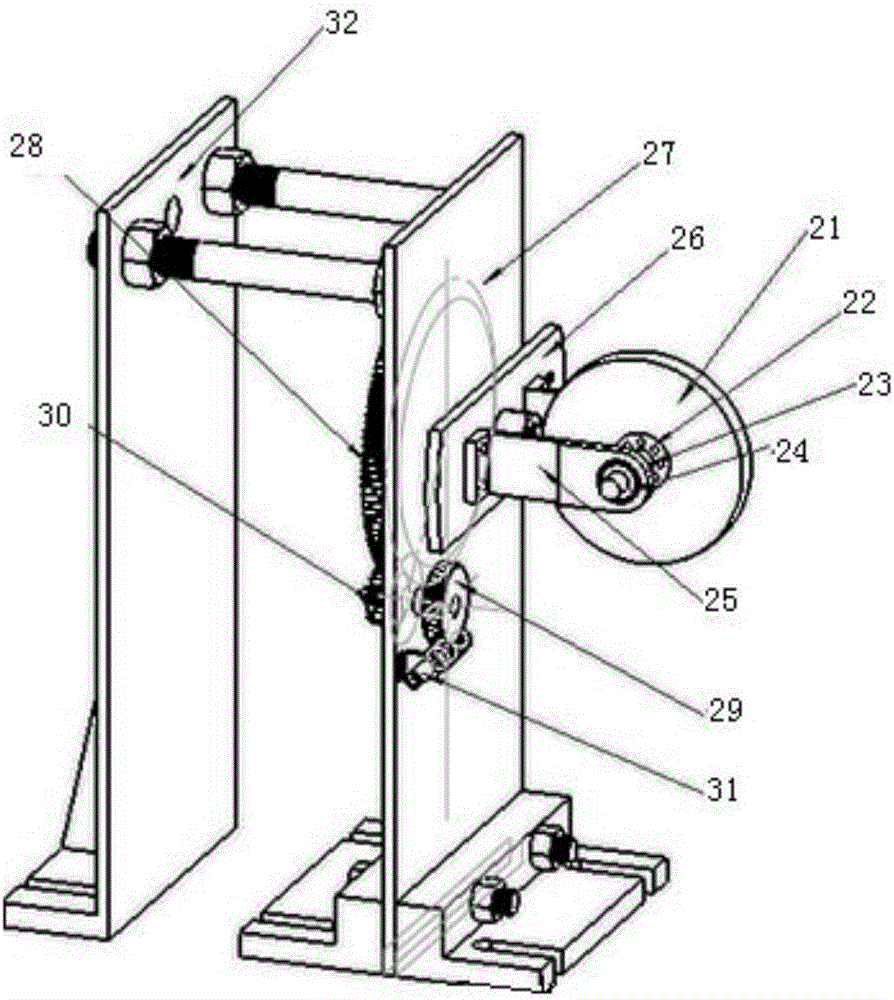

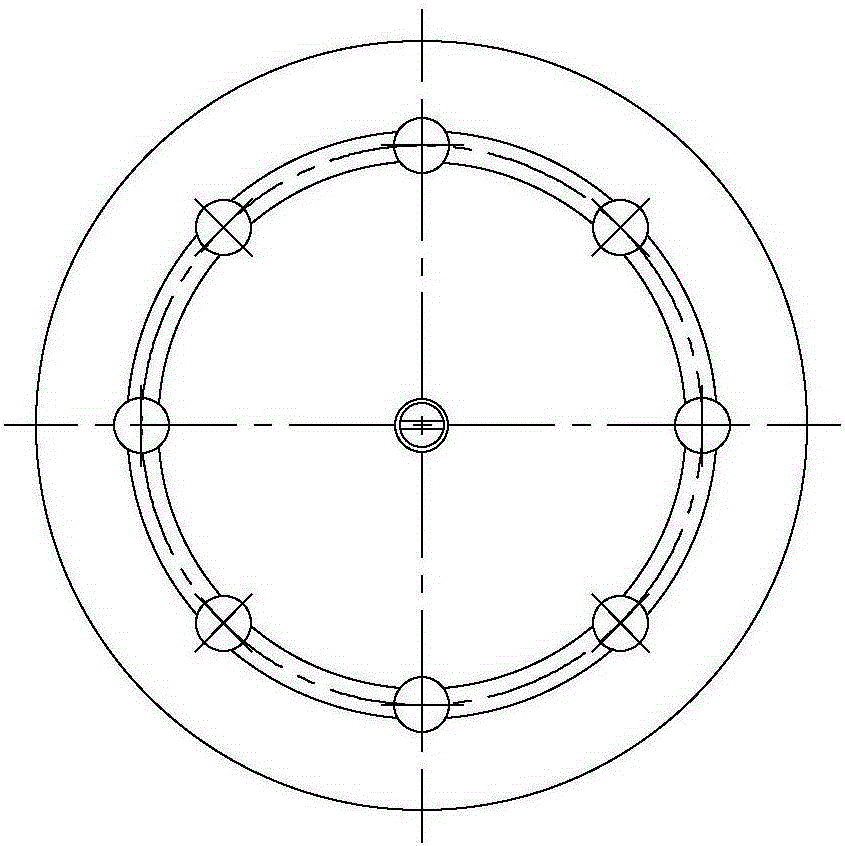

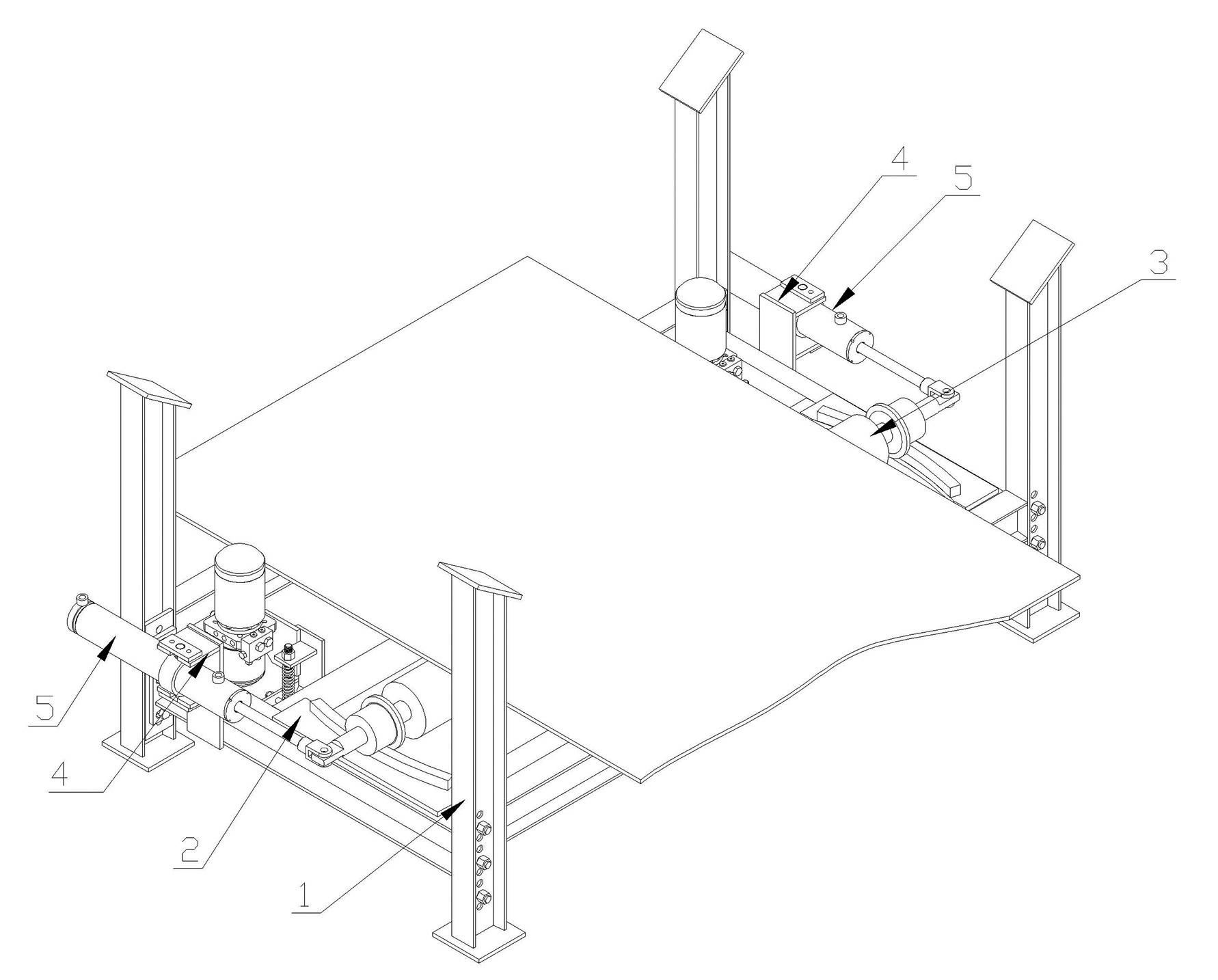

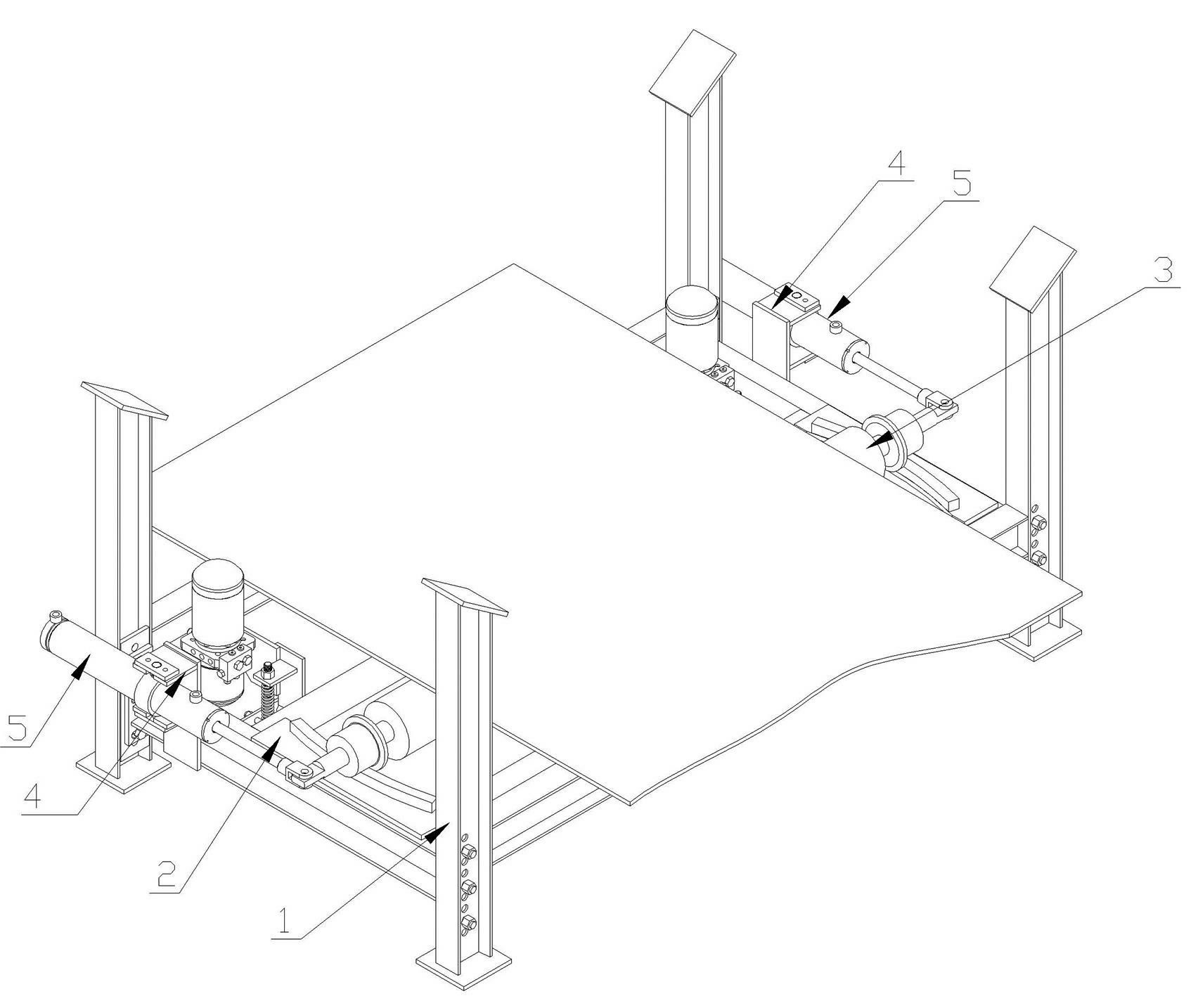

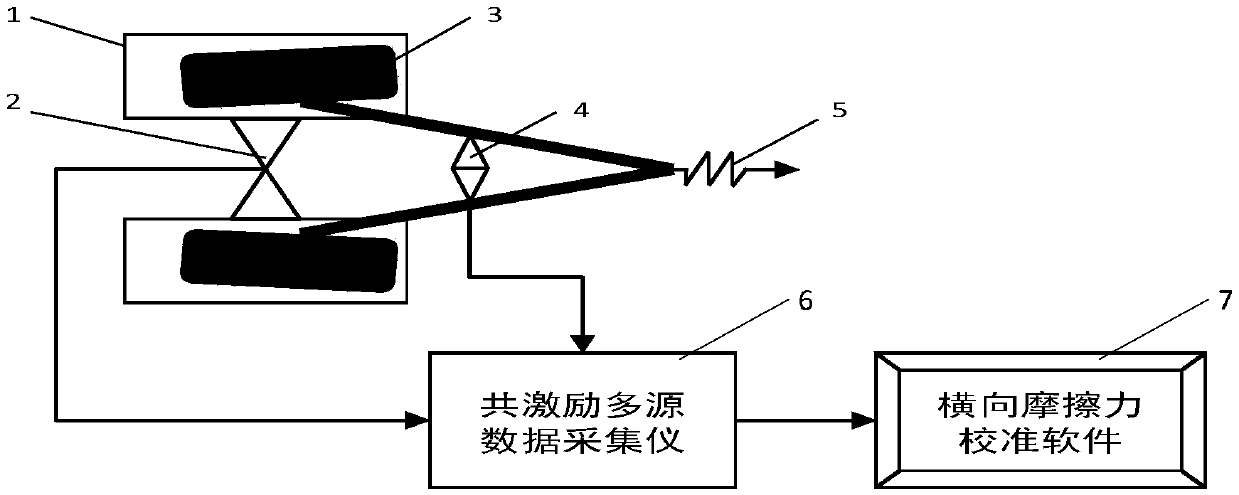

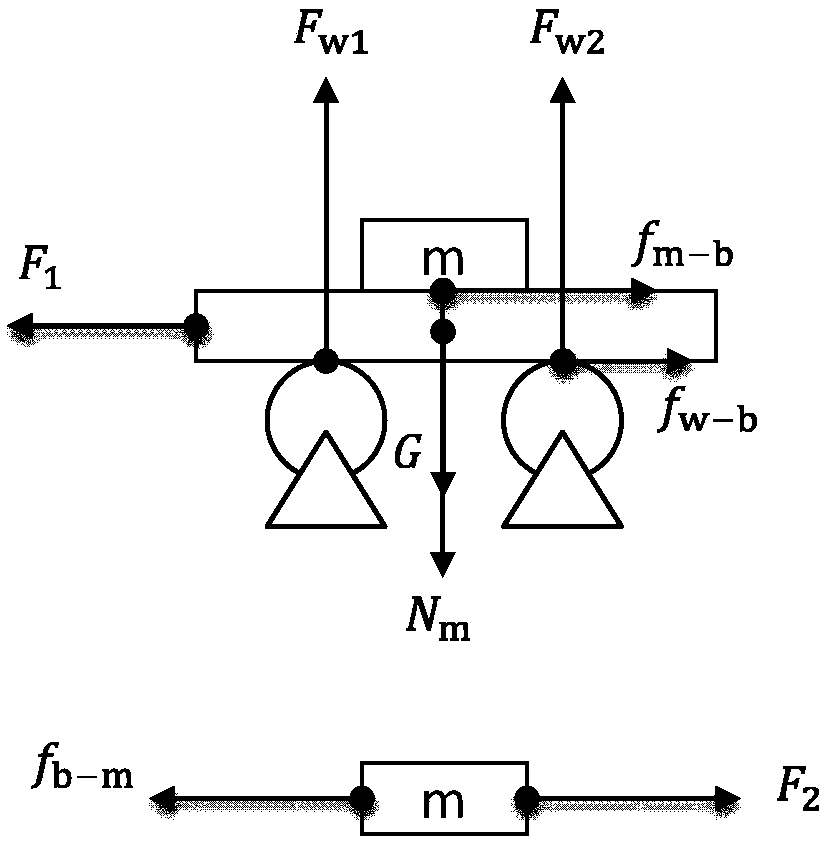

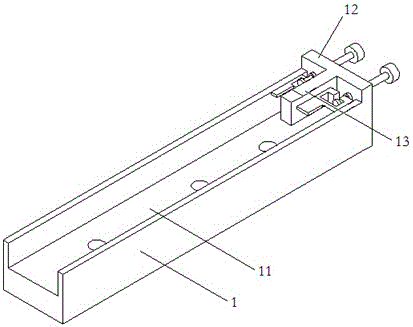

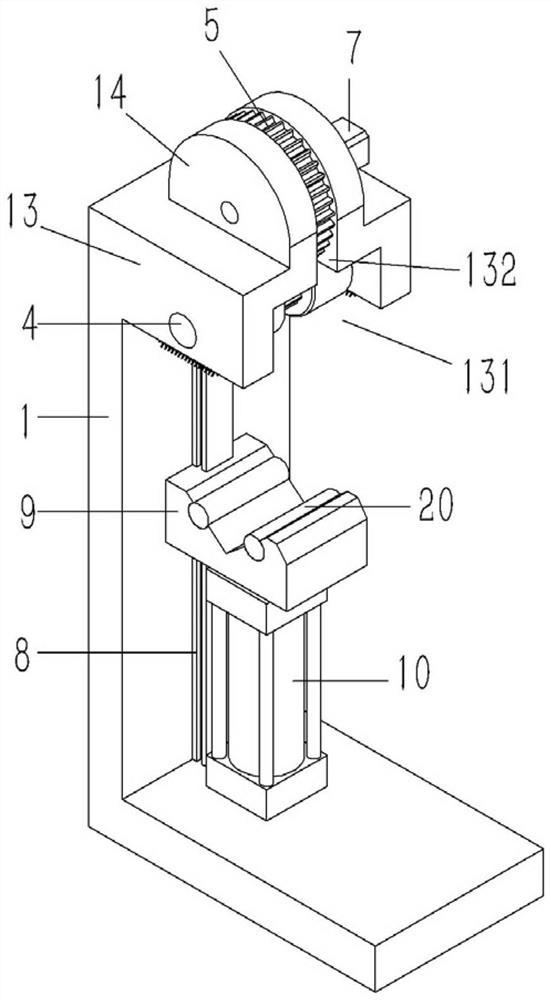

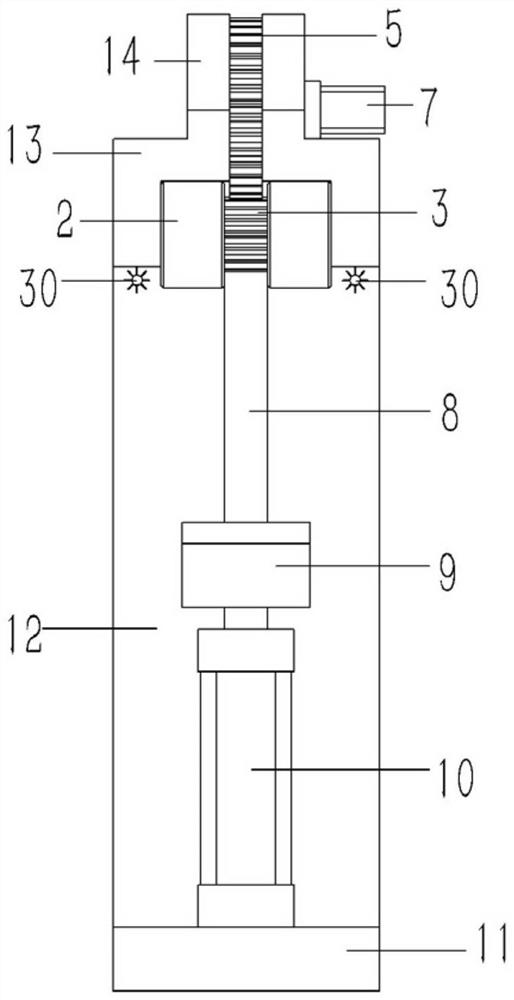

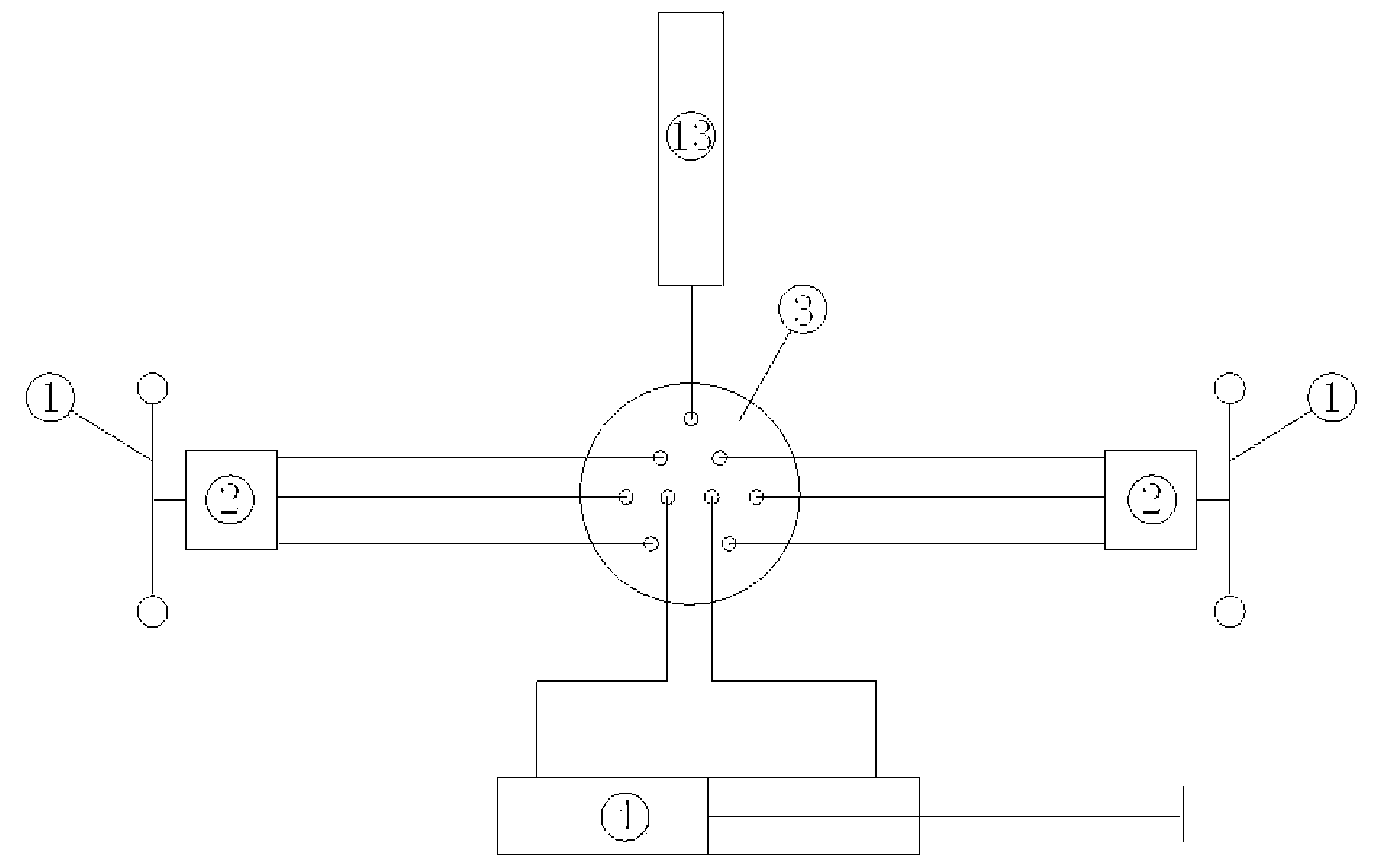

Transverse friction force calibration device and calibration method

ActiveCN109668682ADetermine the dispersionUsing mechanical meansForce/torque/work measurement apparatus calibration/testingTransverse frictionsComputer module

The invention provides a transverse friction force calibration device and method. The device is characterized in that a drawing device provides the drawing force for two testing wheels through two drawing force arms, the two testing ends of a testing system force sensor are connected with the corresponding positions of two drawing cables, the two testing ends of a reference force sensor are connected with two friction testing plates, the output end of the reference force sensor is connected with the input end of a co-excitation multi-source data acquisition machine, and the output end of the co-excitation multi-source data acquisition machine is connected with a friction force calibration software module; the co-excitation multi-source data acquisition machine is used for acquiring data from the reference force sensor and the testing system force sensor simultaneously, and the reference data sequence and the to-be-calibrated data sequence are obtained respectively; and the friction force calibration software module is used for calibrating the to-be-calibrated data sequence by utilizing the reference data sequence so as to achieve the technical effect that the transverse friction force testing result of the testing system is calibrated.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

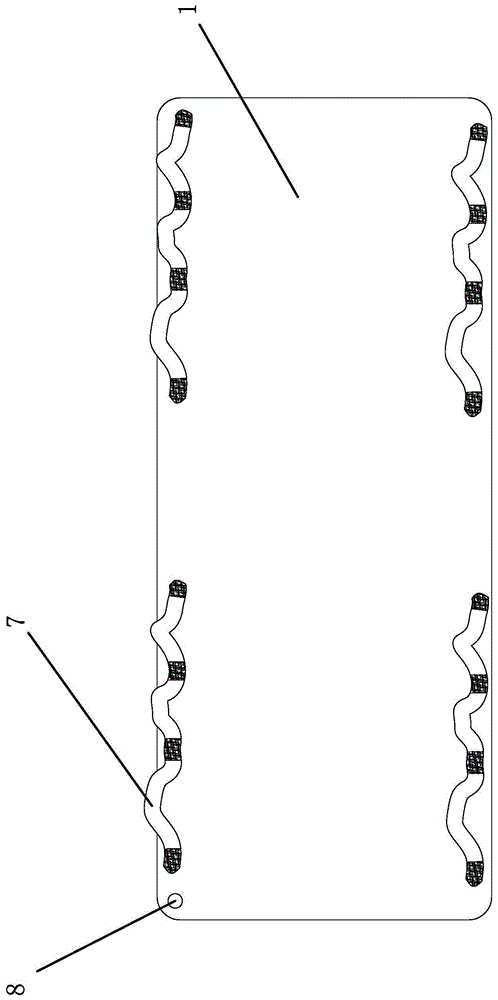

Urine mat convenient in separation from bed

The invention belongs to the technical field of urine mats and provides a urine mat convenient in separation from a bed. The urine mat comprises a body, a chip and pull ropes, the body is formed by integral quilting of five fabric layers including an upper contact layer, a water absorption layer, a water-resistant layer, a protection layer and a lower bottom moving layer sequentially from top to bottom, the upper contact layer and the protection layer are made of warp knitted fabrics, the water absorption layer is made of needle-punched nonwoven fabrics, the water-resistant layer is made of TPU (thermoplastic polyurethanes) composite membranes, and the lower bottom moving layer is made of satin fabrics with transverse friction coefficients larger than longitudinal friction coefficients. The chip is arranged at the edge of the body and positioned between the protection layer and the water-resistant layer, and the pull ropes are sewn on the outer periphery of the body. The urine mat has the advantages that the body is highly comfortable, excellent in water absorption performance and high in breathability and moisture resistance; owing to the pull ropes, a patient lying on the urine mat can be transferred conveniently; by the aid of the chip, relevant information can be stored in the chip to make it convenient for people to know.

Owner:HAINING YIKANG TEXTILE

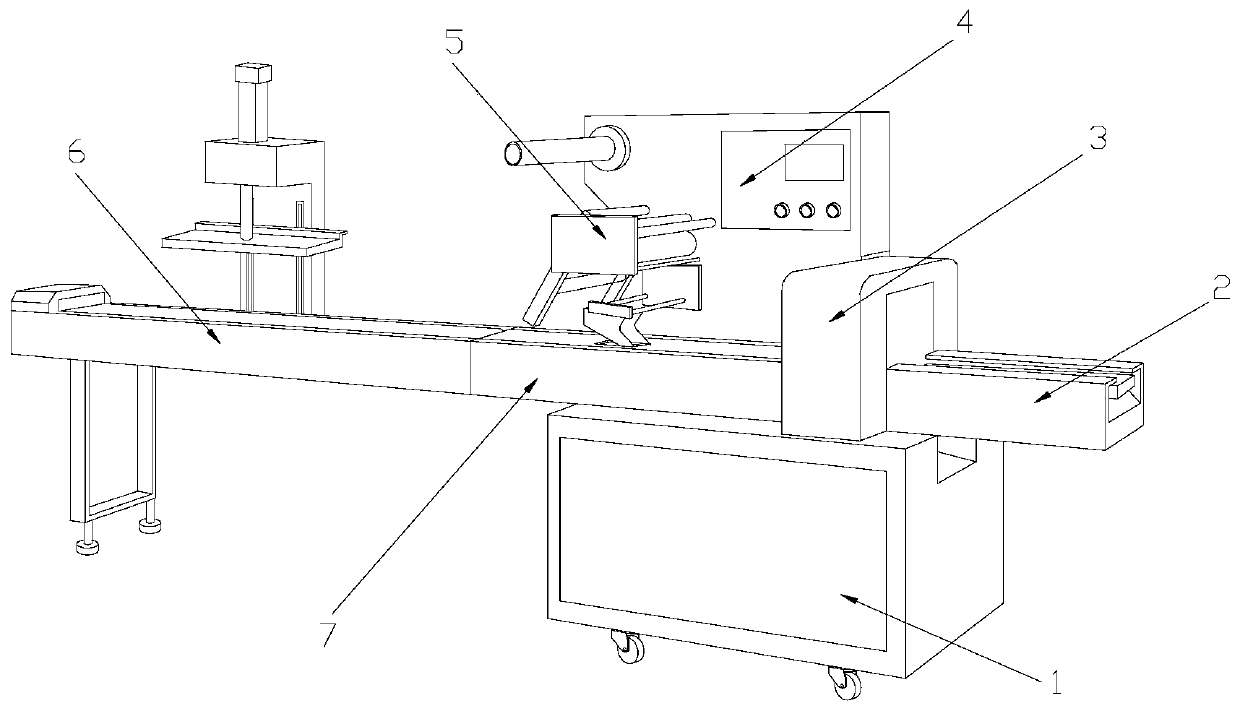

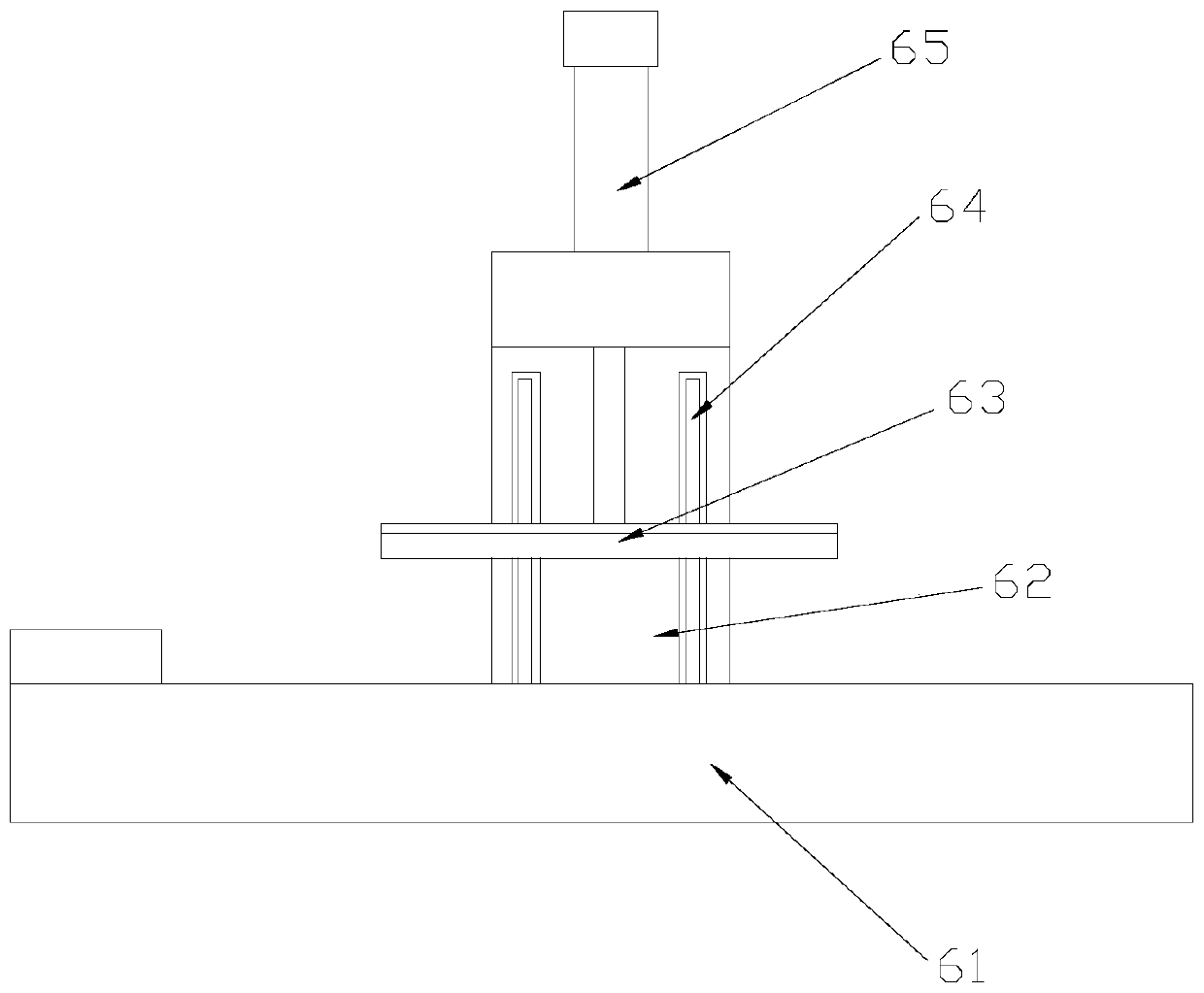

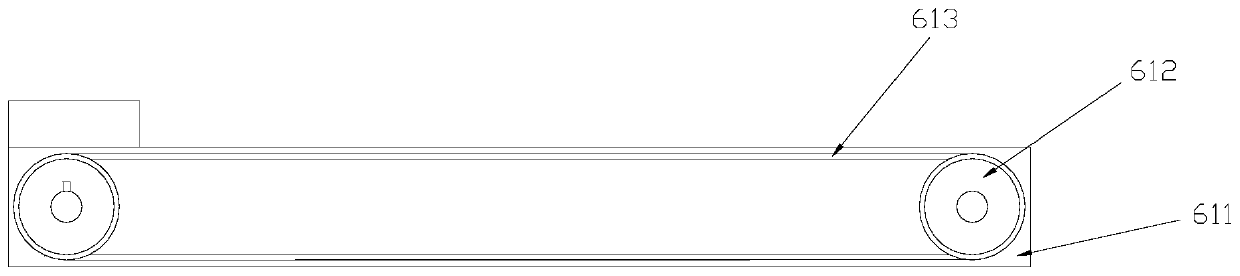

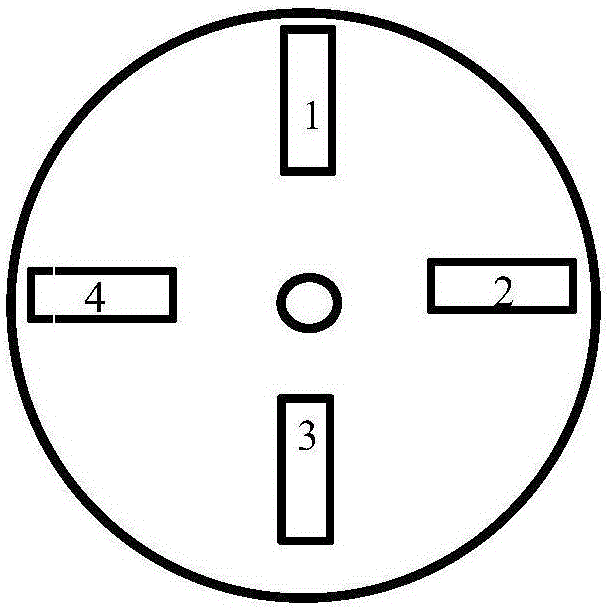

All-in-one shearing and packaging machine for plastic product

ActiveCN110170897AAvoid piercingImprove aestheticsEdge grinding machinesTransmission beltTransverse frictions

The invention discloses an all-in-one shearing and packaging machine for a plastic product. The all-in-one shearing and packaging machine comprises a box body, a discharge transmission belt, a dryingbox, a control panel, a packaging machine, a shearing mechanism and a conveying belt, wherein the box body is horizontally arranged at the lower end of the discharge transmission belt, and the dryingbox is vertically arranged at the upper end of the box body and is arranged on the left side of the discharge transmission belt; and the lower end of the control panel is connected with the upper endof the box body through a bolt. A sinking type shearing and conveying mechanism is arranged under a pressing-down mechanism. Firstly, the two sides of the plastic product touch a cutter and excess burrs are cut off; as the transverse friction force on the upper end of the plastic product is removed through balls at the lower end of a pressing-down plate, the plastic product is driven to continue to move forwards and touches and rubs with a grinding plate at the same time; as the adsorption force of adsorption holes to the plastic product is greater than the friction force of the grinding plate, the plastic product can be pushed to move forwards for grinding; and thus, the all-in-one shearing and packaging machine can treat the burrs on the two sides of the plastic product to prevent the burrs from puncturing a packaging bag during packaging, and the beauty of the product is improved.

Owner:潍坊卓凡包装科技有限公司

Measurement method of transient transverse friction coefficient of rolling contact point based on optical fiber gratings

ActiveCN106769840AAddress cross-sensitivity issuesUsing mechanical meansMaterial analysisGratingTransverse force

The invention discloses a measurement method of a transient transverse friction coefficient of a rolling contact point based on optical fiber gratings. The measurement method comprises the following steps of symmetrically pasting the optical fiber gratings with different central wavelengths on the two sides of a big wheel, sequentially marking the optical fiber gratings, adjusting a certain normal force generated by the big wheel and a small wheel at the rolling contact point, forming a certain attack angle between the big wheel and the small wheel to allow the big wheel to generate a certain transverse force at the rolling contact point, controlling the rotating speed of the big wheel, transmitting a strain signal generated by the big wheel to the optical fiber gratings when the big wheel rotates, transmitting a built-in light source of a demodulator to the optical fiber gratings via an optical fiber grating rotary connector, allowing the optical fiber gratings to generate strain signals, demodulating the strain signals of the optical fiber gratings with the demodulator, transmitting demodulated signals to an industrial personnel computer, allowing the industrial personnel computer to acquire and analyze the demodulated signals, and calculating transient positive pressure and friction of the big wheel at the rolling contact point according to wavelength shift of the optical fiber gratings.

Owner:WUHAN UNIV OF TECH

Pendulum type deviation adjusting carrier roller and using method thereof

The invention provides a pendulum type deviation adjusting carrier roller and a using method thereof. The pendulum type deviation adjusting carrier roller comprises a machine frame of a conveying machine and a deviation correcting carrier roller body, wherein the deviation correcting carrier roller body is arranged on the machine frame, the bottom of the deviation correcting carrier roller body is fixed on a base plate, and the base plate is hinged to the machine frame. According to the pendulum type deviation adjusting carrier roller and the using method thereof, the structure is simple, due to the fact that when a belt deviates, a pendulum type deviation adjusting mechanism can be used for applying the transverse eccentric force which is similar in the deviation direction to the automatic deviation adjusting carrier roller body, the automatic deviation adjusting carrier roller body can generate pendulum type motion and moves to an inclined state around a hinge point with the machine frame to apply the transverse friction counter force which is deviated towards the central axis to the belt so that the belt can automatically adjusting the deviation to a normal orbit, meanwhile, the automatic deviation adjusting carrier roller body can also be reset gradually, the provided friction force can be gradually decreased along with the reset of the belt, and therefore the self-adaptive deviation adjusting effect can be achieved.

Owner:FUJIAN AGRI & FORESTRY UNIV

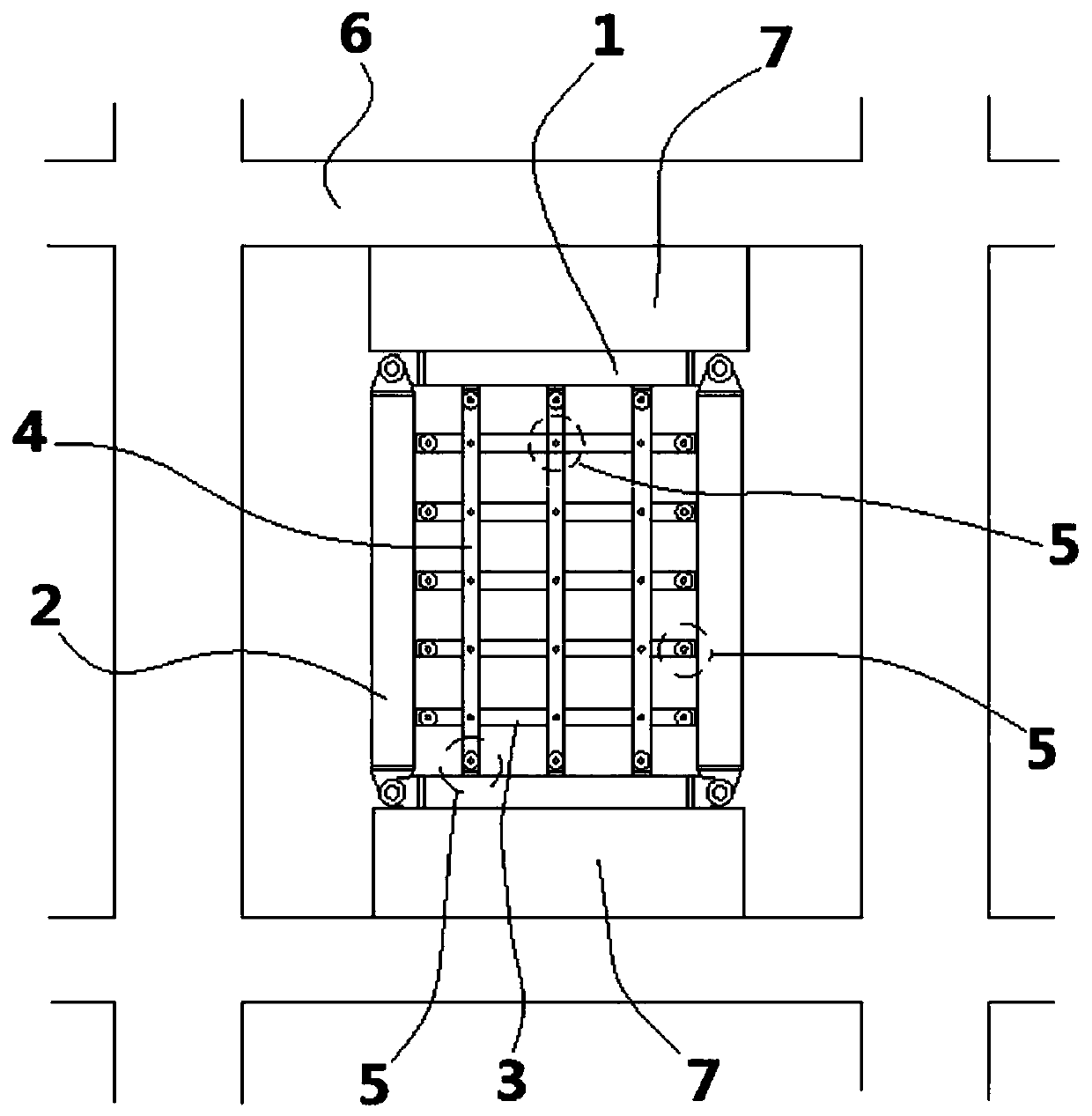

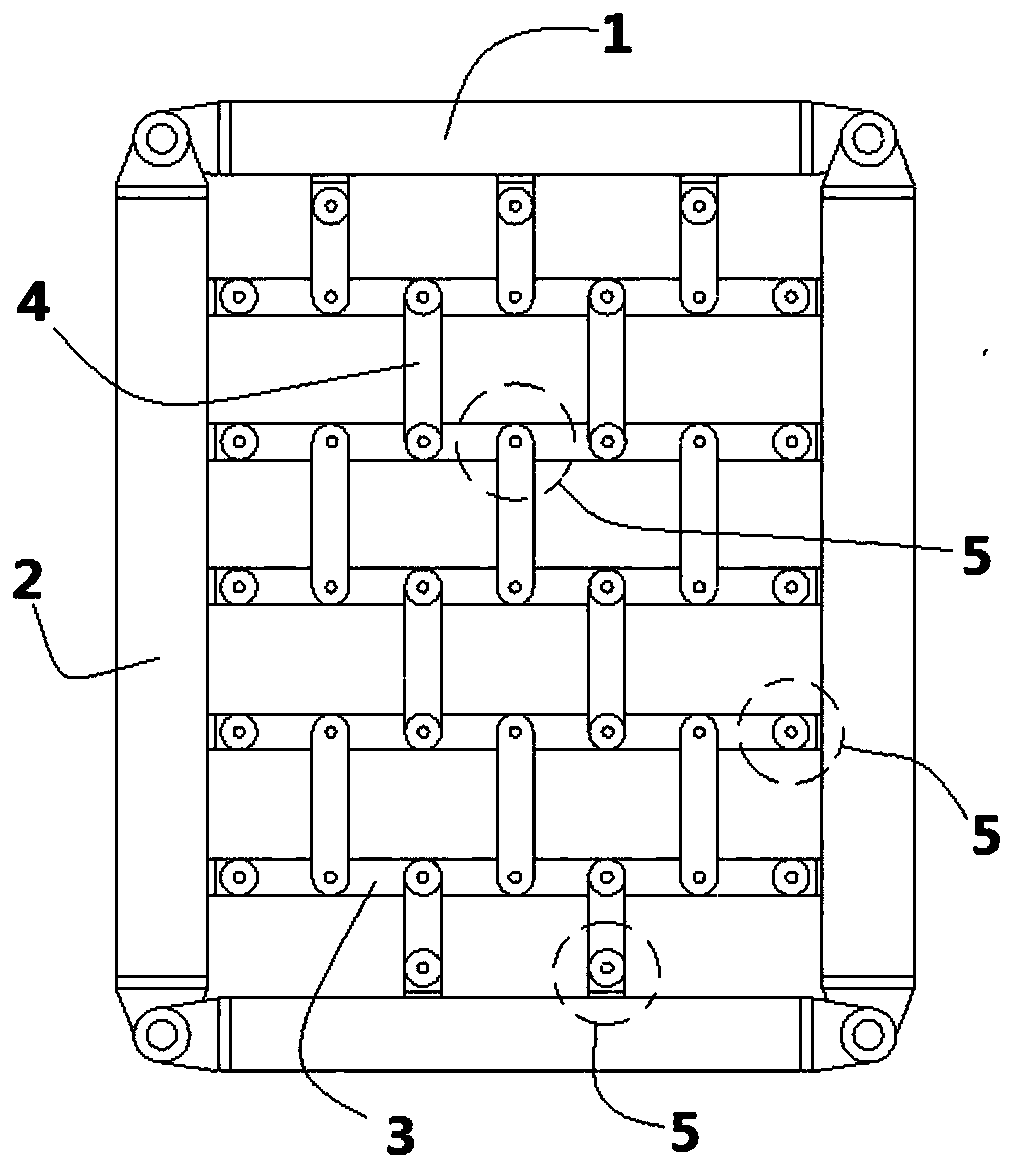

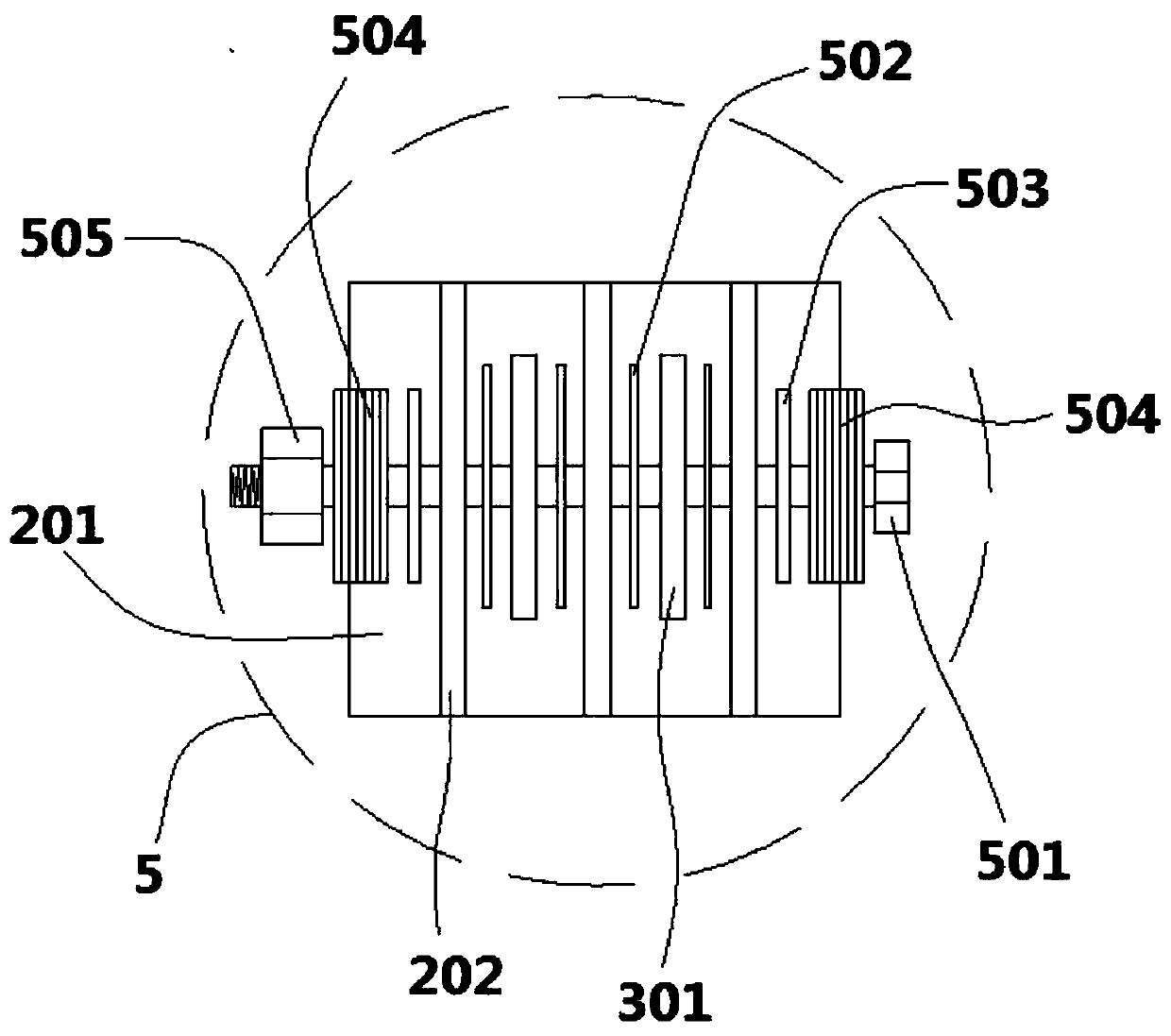

Rotating type friction energy dissipation wall

PendingCN109914635AExtended service lifeAchieve dissipationWallsProtective buildings/sheltersTransverse frictionsStructural engineering

The invention discloses a rotating type friction energy dissipation wall, and relates to the field of seismic reduction control of building structures. The invention aims at providing a friction energy dissipation wall capable of realizing energy dissipation-seismic reduction by using displacement deformation in a structure under the action of an earthquake. In order to realize the aim, the rotating type friction energy dissipation wall is characterized in that a movable frame is connected between upper and lower beams of a building; a plurality of transverse friction steel plate groups and aplurality of longitudinal friction steel plate groups are arranged in the movable frame, and the horizontal friction steel plate groups and the longitudinal friction steel plate groups are overlappedin a crossed way; movable friction nodes are arranged at the overlapped parts. When the building structure is subjected to a horizontal earthquake action, the movable frame is deformed, the friction nodes are rotated, and energy dissipation is achieved by means of mutual friction of transverse friction steel plates and longitudinal friction steel plates. The stability of friction between the friction steel plates can be maintained by means of friction plates in the friction nodes, and hard gaskets in the friction nodes can prevent the friction steel plates from being damaged, so that the service lives of the friction steel plates are prolonged.

Owner:CHONGQING UNIV

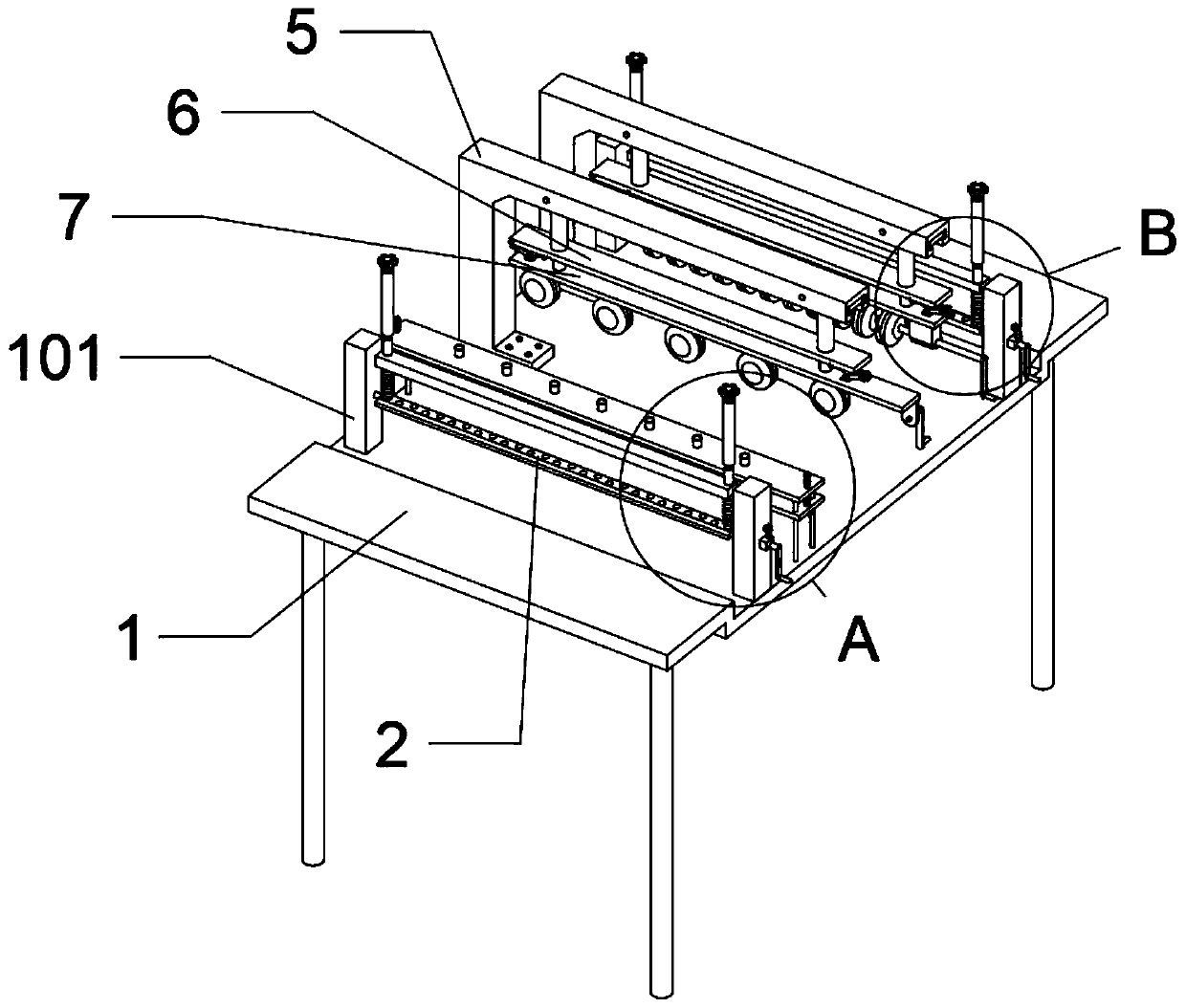

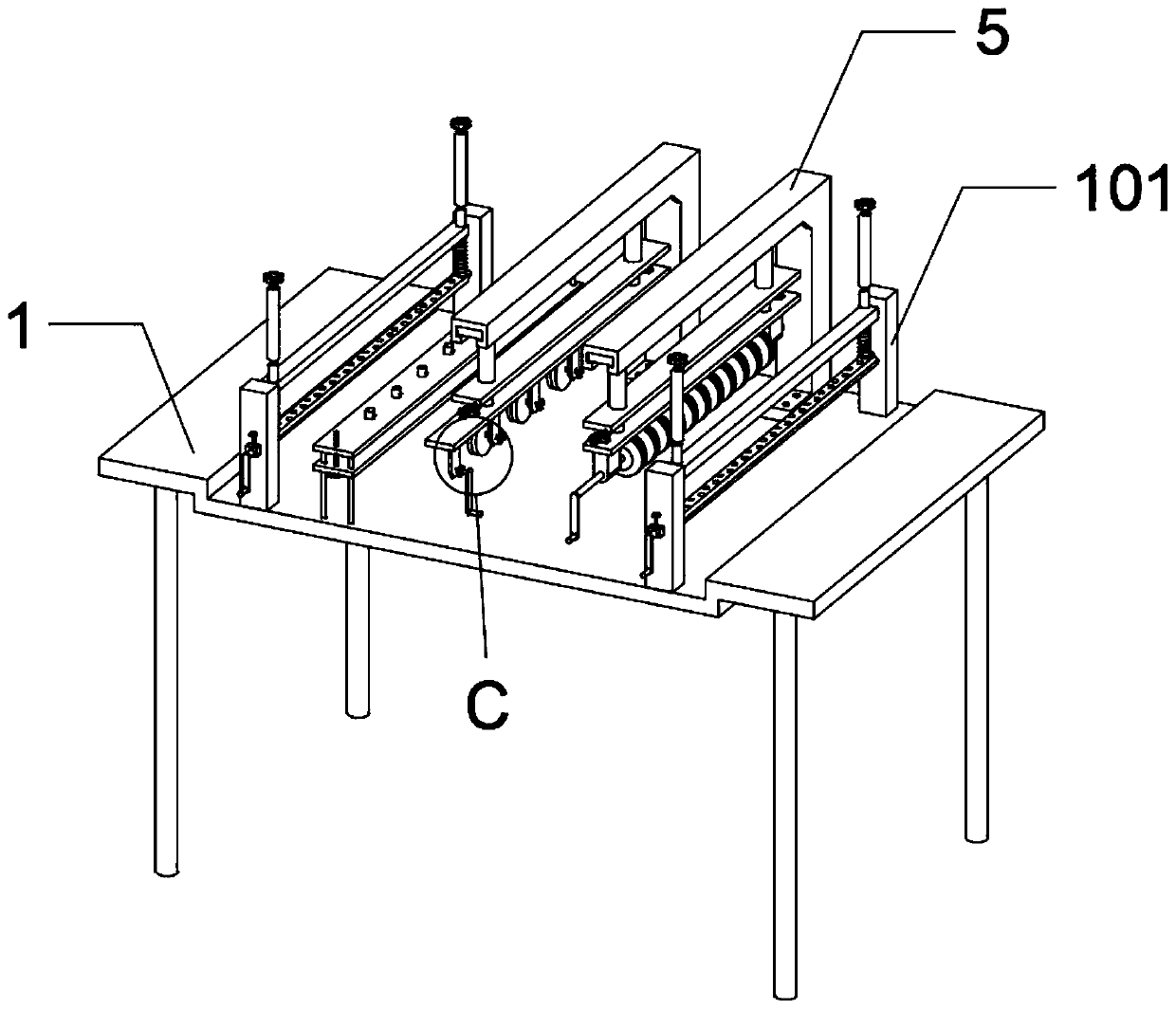

Seat cover clothinspection and test platform

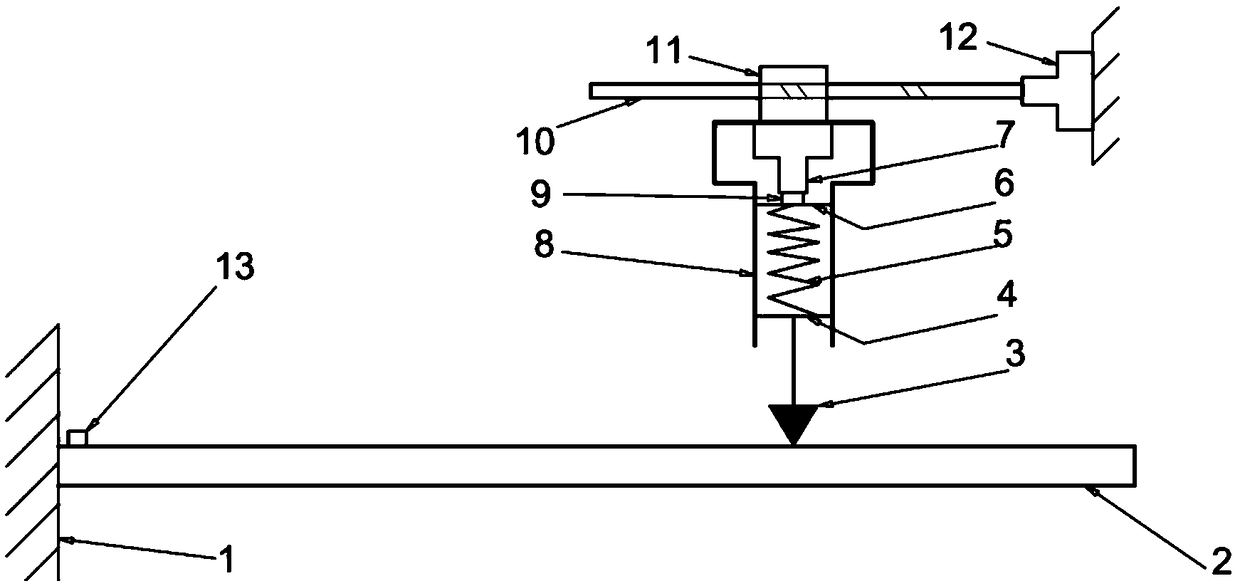

InactiveCN110501248AImprove stabilityEasy to fixMaterial strength using tensile/compressive forcesPermeability/surface area analysisFixed-functionTransverse frictions

The invention provides a seat cover cloth inspection and test platform. The platform comprises a machine bench, cloth fixing frames, a packing square cylinder, a fixed bottom plate, a rocker A, a guide round rod, a fixed top plate, a locking cylinder, processing frames, a processing conductor, a transverse friction frame, a rocker B, a longitudinal friction frame, a rotating shaft frame, a rockerC, a lifting frame, a ventilation test plate A, a ventilation test plate B and a friction wheel. The cloth fixing frames are integrally arranged on two sides of two ends of a top of the machine bench.Two sets of machining frames are fixedly arranged on one side of the top of the machine bench through bolts, and T-shaped sliding grooves are arranged in bottom sides of the tops of the machining frames. Through arranging the fixed bottom plate and the fixed top plate, a cloth fixing function with strong stability is provided for the test platform, and an inclined plane structure and a sphericalstructure are arranged between the fixed bottom plate and the fixed top plate so that stability is increased for cloth fixation. The fixed bottom plate and the fixed top plate can be cooperated with the rocker A to rotate so that cloth is secondarily tensioned, and use is convenient.

Owner:湖北增金汽车零部件有限公司

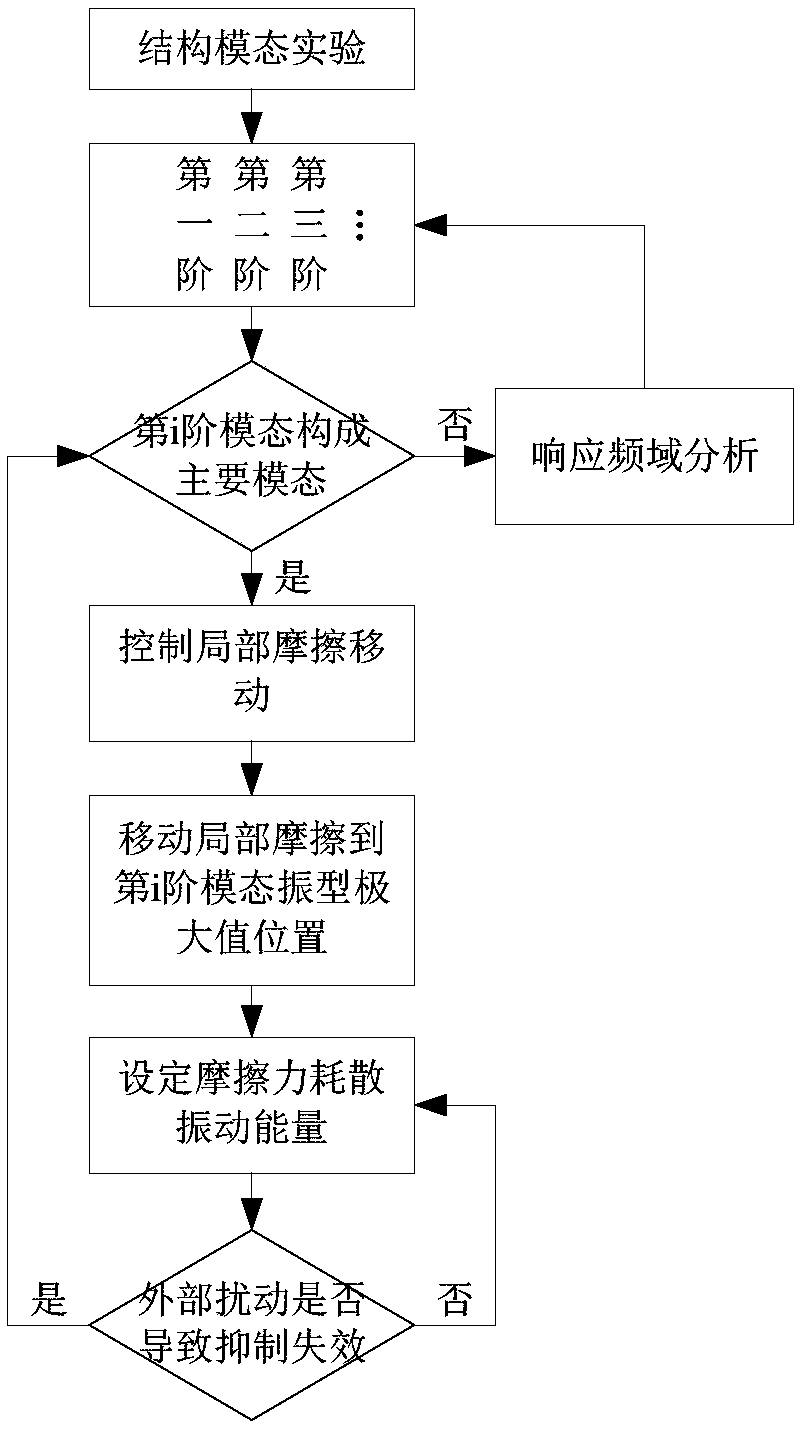

Damping method and device for friction induction modal conversion

ActiveCN109457827ASolve the problem of destructive accidentsBridge structural detailsProtective buildings/sheltersResonanceTransverse frictions

The invention relates to a damping method and device for friction induction modal conversion. The method comprises the steps of performing pre-modal experimental analysis on a beam structure, obtaining response signals of the beam structure, and determining a main modal forming response, wherein the main modal is the main composition for the beam structure response signal under the current excitation condition; performing damping treatment, wherein normal pressure is applied to the beam structure at any vibration mode extreme value position corresponding to the main modal of the beam structure, transverse friction force along the beam structure is generated, normal pressure is gradually increased, and response to the beam structure is detected; if response is lowered to be not larger thana set threshold value, determining the main modal forming the response again, and repeatedly executing the damping treatment process till the response of the beam structure is lowered to be larger than a set threshold value. Pre-modal experimental analysis is performed on the beam structure, the main modal is determined, damping treatment is performed according to the main modal, the method is simple and reliable, and large movement of the structure caused by mismatching of modals or resonance can be greatly lowered.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

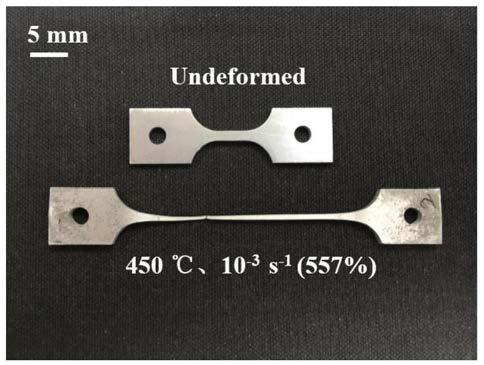

Preparation method of aluminum-based composite material

The invention provides a preparation method of an aluminum-based composite material. The preparation method of the aluminum-based composite material comprises the following steps that a to-be-machinedaluminum-based composite material plate after being subjected to pretreatment is horizontally placed on a cushion plate and is clamped and fixed; a stirring head of friction stir welding is insertedinto the surface of the aluminum-based composite material plate at a rotating speed of 10-2000 rpm until the lower end of a shaft shoulder is in tight contact with the upper surface of the aluminum-based composite material plate, and the aluminum-based composite material plate is preheated; and transverse friction stir welding and longitudinal friction stir welding are carried out to the surface of the aluminum-based composite material plate through the stirring head at a certain walking speed until the whole aluminum-based composite material plate is machined completely. According to the preparation method of the aluminum-based composite material, the hardness of an in-situ nanoparticle reinforcing phase TiB2 added into an aluminum alloy is high, the heat stability is good, inhibiting effects on grain growth and void formation in high-temperature deformation of crystalline grains are achieved, and thus the material can have excellent superplasticity.

Owner:SHANGHAI JIAO TONG UNIV

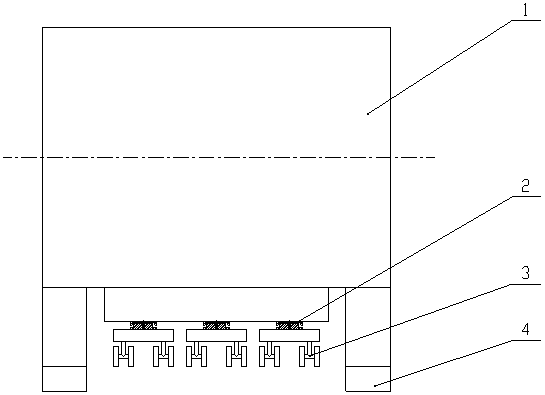

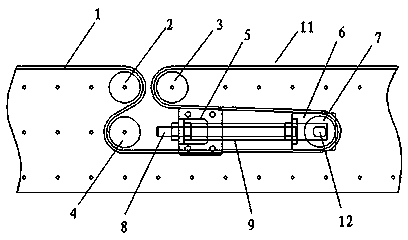

Mechanism preventing middle portion of bearing surface of flat belt conveyer from deviating

InactiveCN103922081AIncrease lateral frictionAchieve the purpose of normal operationConveyorsTransverse frictionsEngineering

The invention discloses a mechanism preventing middle portion of the bearing surface of a flat belt conveyer from deviating. The mechanism is arranged on the bearing surface (11) and comprises a machine frame (8) and a conveying belt (1). The machine frame is provided with a first belt pressing cylinder (2), a second belt pressing cylinder (3), a third belt pressing cylinder (4) and a tension cylinder (7). The first belt pressing cylinder and the second belt pressing cylinder are located above the third belt pressing cylinder and the tension cylinder, the conveying belt sequentially passes the first belt pressing cylinder, the second belt pressing cylinder, the third belt pressing cylinder and the tension cylinder, and a tensioning and deviation correcting device is further disposed on the machine frame between the third belt pressing cylinder and the tension cylinder. The tensioning and deviation correcting device is arranged on the bearing surface of the conveying belt in the middle of the belt conveyer, so that transverse friction of the conveying belt and the cylinders is increased, the conveying belt can not be influenced of conveying belt deviation caused by inclined upward loading impact during operation, deviation can be corrected at any time, and accordingly the aim that materials operate normally on the belt conveyer is achieved.

Owner:董守云

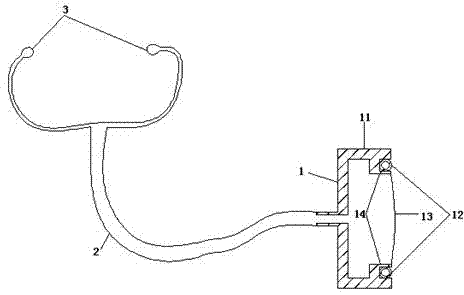

Anti-noise stethoscope

InactiveCN104739440AReduce friction noiseReduce distractionsStethoscopeTransverse frictionsEngineering

The invention provides an anti-noise stethoscope which comprises a sensing cavity, a sound transmitting pipeline and earplugs which are sequentially connected. The sensing cavity comprises a shell, an annular hose is clamped to the inner side of an opening of the shell, the annular hose is made of an inflation rubber pipe, an annular wall is also clamped to the inner side of the annular hose, the outer wall of the annular wall makes direct contact with the annular hose, the front end of the annular wall is covered with a pickup film which is an elastic resin film, and the annular wall and the pickup film are integrally formed through a pickup film material. The anti-noise stethoscope can lower transverse friction noise of the sensing cavity, reduces interference and facilitates auscultation.

Owner:朱小菊

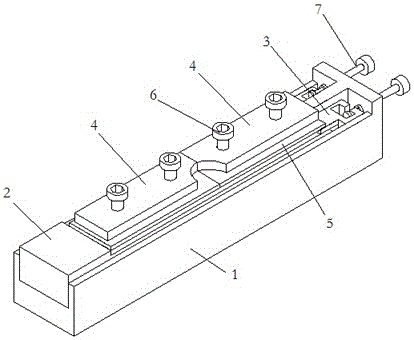

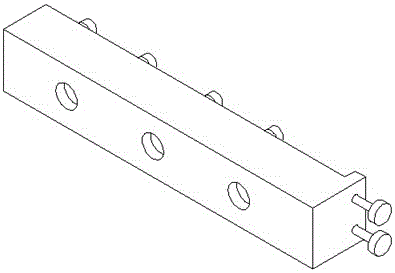

Batch chamfering clamp of acousto-optic crystal blocks

ActiveCN106112595ARapid positioningSave the process of looking for correctionsPositioning apparatusMetal-working holdersTransverse frictionsAcousto-optics

Owner:CHINA ELECTRONICS TECH GRP NO 26 RES INST

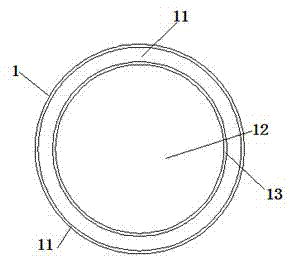

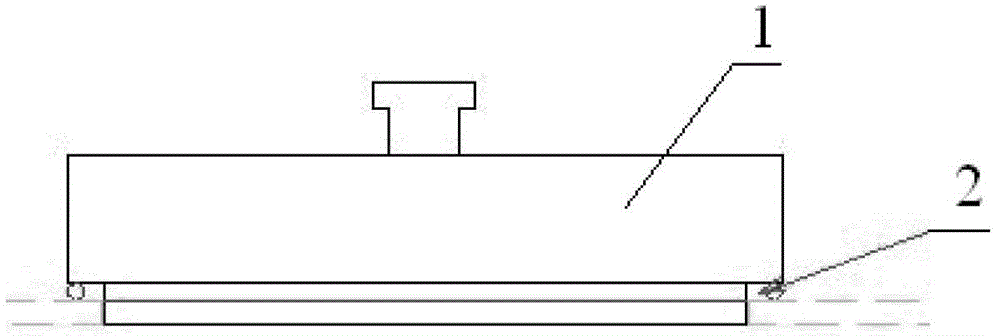

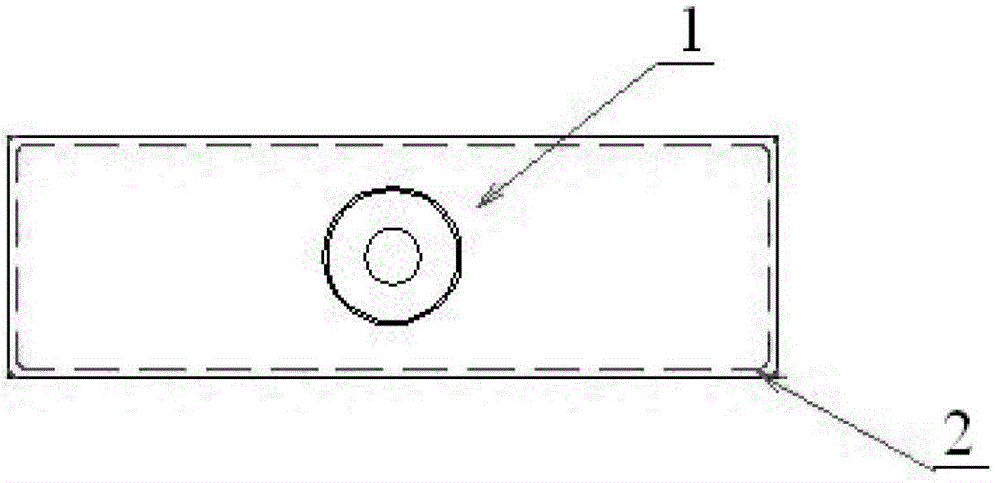

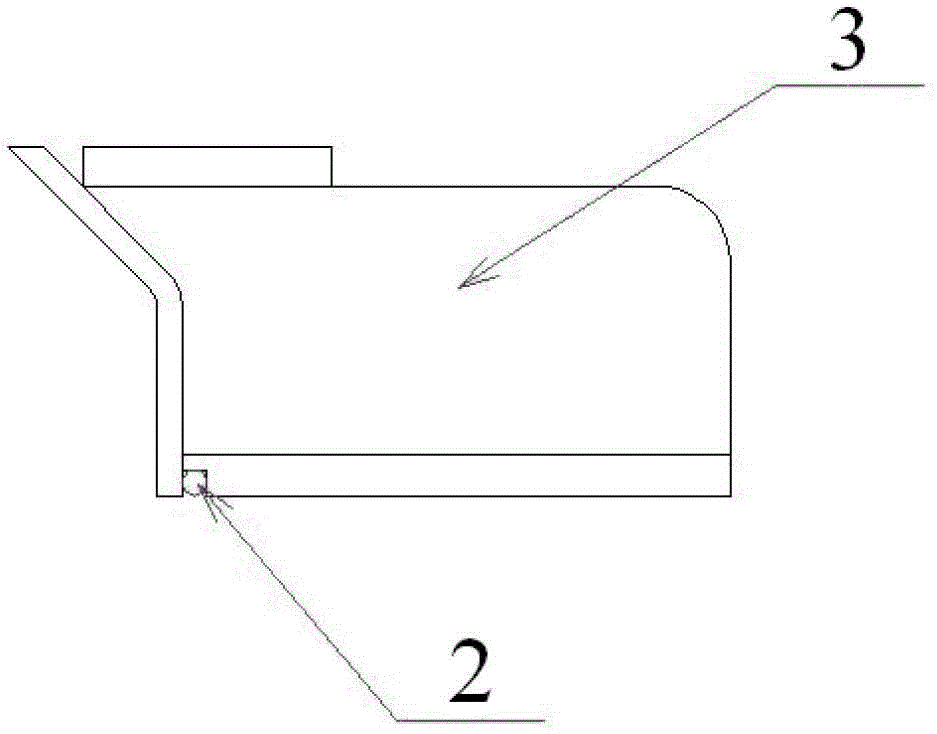

Device for increasing transverse friction of template for manufacturing precast concrete

InactiveCN104149188ASimple structureAdd grooveMould auxillary partsAuxillary shaping apparatusTransverse frictionsEngineering

The invention relates to a device for increasing the transverse friction of a template for manufacturing precast concrete. The device is used for fixing a side die (3). The device comprises a magnet (1) and a rubber strip (2). The magnet (1) is fixed to the side die (3), a groove (1) is formed in the outer circle of the magnet (1), the rubber strip (2) is arranged in the groove, the friction between the magnet (1) and the side die (3) is increased, and the side die (2) is prevented from sliding. Compared with the prior art, the device has the advantages of being simple in structure, easy to main, capable of reducing workloads and the like.

Owner:SHANGHAI JONSON MACHINE

Bath towel and production technology thereof

InactiveCN109907678AEase of mass productionIncrease lateral frictionDomestic applicationsUser needsTransverse frictions

The invention provides a bath towel and a production technology thereof, and relates to the field of articles for daily life. The production technology of the bath towel, provided by the invention, ischaracterized in that first lint cloth and second lint cloth are fixed at two sides of towel cloth respectively. The first lint cloth comprises first sticking lint; the second lint cloth comprises second sticking lint matched with the first sticking lint in a sticking manner. The technology is simple and feasible, has relatively high production efficiency and is convenient for batch production ofthe bath towels. The first sticking lint and the second sticking lint, which can be matched in the sticking manner, are arranged at two sides of the bath towel produced by the technology. If a user needs to wrap a body with the bath towel, two side faces are in mutual contact with each other; in a contacting process, the first sticking lint and the second sticking lint are matched in the stickingmanner, so that a transverse friction force between the bath towel is increased and the sticking stability of the two side faces is enhanced; however, the two side faces also can be easily separatedwhen the user uncovers a sticking part of the two side faces by hands, so that the bath towel is convenient to use; the bath towel is very stable when being wrapped on the body of the user and the bath towel is extremely convenient to take off.

Owner:伍天俊雄

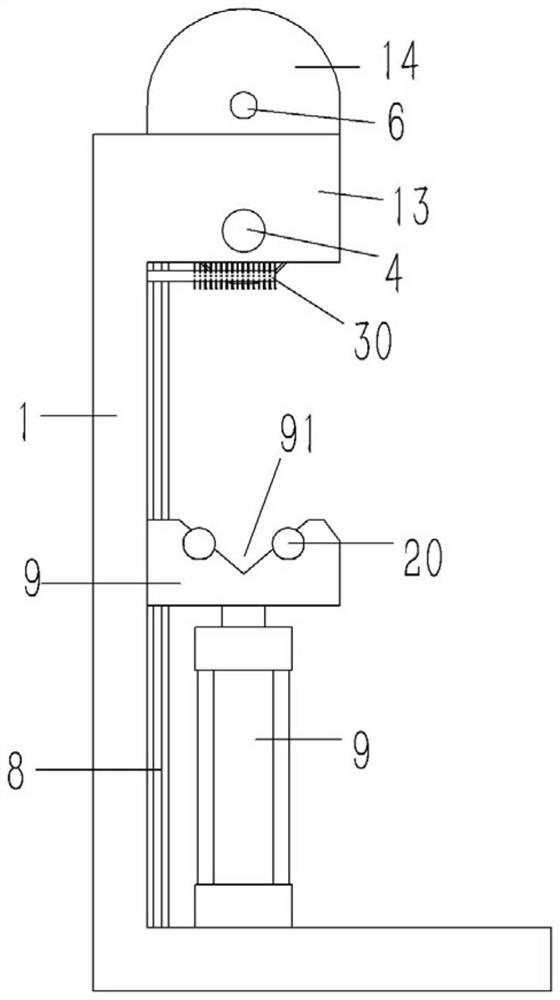

Shallow-layer rapid pile driver suitable for soft texture surface

ActiveCN109736308ASmall lateral resistanceFall in favor ofBulkheads/pilesTransverse frictionsDrive motor

The invention discloses a shallow-layer rapid pile driver suitable for a soft texture surface. The shallow-layer rapid pile driver comprises a pile frame, a pile hammer, a shifting mechanism and lifting equipment. The shifting mechanism comprises a pair of guide rail cross beams between which a first sliding block and a second sliding block are arranged, Side stop blocks are arranged at the two ends of the guide rail cross beams respectively, tension springs are arranged between the first sliding block and the side stop blocks and between the second sliding block and the side stop blocks, round holes are formed in the first sliding block and the second sliding block, cams are installed at the power output ends of driving motors and located in the round holes, a first shifting arm is arranged on the first sliding block, and a second shifting arm is arranged on the second sliding block. Compared with the prior art, the shallow-layer rapid pile driver suitable for the soft texture surfacehas the beneficial effects that through the opposite movement of the first shifting arm and the second shifting arm, the pile hammer inclines slightly in the descending process, when the pile hammerin the slightly inclined state collides with the pile body, the pile body is expanded slightly in a pile hole in the ground along with transverse friction force, so that the pile body sinks easily, and the pile driver is suitable for being used in the soft surface environment.

Owner:YANCHENG INST OF TECH

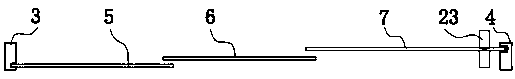

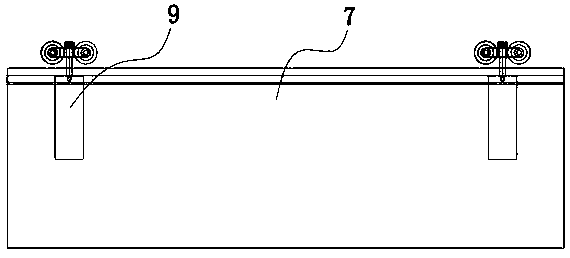

Adjustable height shower room with transverse frictional linkage

The invention discloses an adjustable height shower room with transverse frictional linkage, comprising an upper rail, a lower rail, a first side plate and a second side plate; fixed glass, moving middle glass and moving door glass are mounted between the upper rail and the lower rail in cross manner; first glass lift-clamp components and spring middle glass clamps are mounted on two sides of thetop and bottom of the moving middle glass respectively; second glass lift-clamp components and spring long glass clamps are mounted on two sides of the top and bottom of the moving door glass respectively. Rubber wheels are rolled between a movement channel and a fixed channel so that the moving middle glass between the first glass lift-clamp components and the spring middle glass clamps is drivenin linked manner, and transverse friction is in linkage with height adjustment; therefore, a shower room glass door is convenient to transversely move and open, and water drops on the glass door never fall onto the ground outside the shower room.

Owner:黄官祥

Grinding device for burr of aluminum end ring of cast aluminum rotor

ActiveCN112775753BEasy to GrindAchieve away fromEdge grinding machinesGrinding drivesGear wheelTransverse frictions

The invention discloses a grinding device for the burr of the aluminum end ring of a cast aluminum rotor. , the lower end surface of the grinding seat is formed with a groove running through the front end surface of the grinding seat, two transverse friction wheels are inserted into the groove of the grinding seat, and the lower end of the friction wheel is exposed to the lower end surface of the grinding seat; friction A transmission gear is inserted between the wheels, the transmission gear and the friction wheel are inserted and fixed on the connecting shaft, and both ends of the connecting shaft are hinged on the grinding seat through bearings; the grinding seat just above the transmission gear The upper end face is formed with a slot which is communicated with the slot, a drive gear is inserted into the slot, and the drive gear meshes with the transmission gear.

Owner:ACCU JIANGSU CO LTD

Passive hydraulic control linked error correcting machine

A passive hydraulic control linkage rectification machine which can rectify and prevent the run deviation of a conveyor belt consists of a hydraulic control detecting and driving system and a linkage rectification mechanism. The hydraulic control detecting and driving system consists of a detecting and driving wheel, an oil pump, a cylinder, a midpoint controlling station, a temperature controller and an oil pipe. The linkage rectification mechanism consists of discrete rollers, roller racks, a universal joint, an arm rod, a connecting rod, a pin and a frame. The hydraulic control detecting and driving system is used to detect the run deviation of the belt and simultaneously supplies power for driving the roller racks to deflect. When the belt runs deviated, the belt drives the detecting and driving wheel to rotate. The detecting and driving wheel drives the oil pump to strike the oil pressure to the midpoint controlling station. A logistic valve group of the midpoint controlling station controls the piston rod of the cylinder (4) to push or pull. The piston rod drives the linkage rectification mechanism to lead the roller (11) on the mechanism to deflect synchronously in the samedirection. An angle is formed between the linear moving direction of the roller after the deflection and the moving direction of the belt, and the transverse friction of the belt generating during the above process drives the belt to run in the middle. The passive hydraulic control linkage rectification machine requires no power and hydraulic function and has the advantages of synchronous linkage, self-defecting, self-driving and self-system.

Owner:林刚

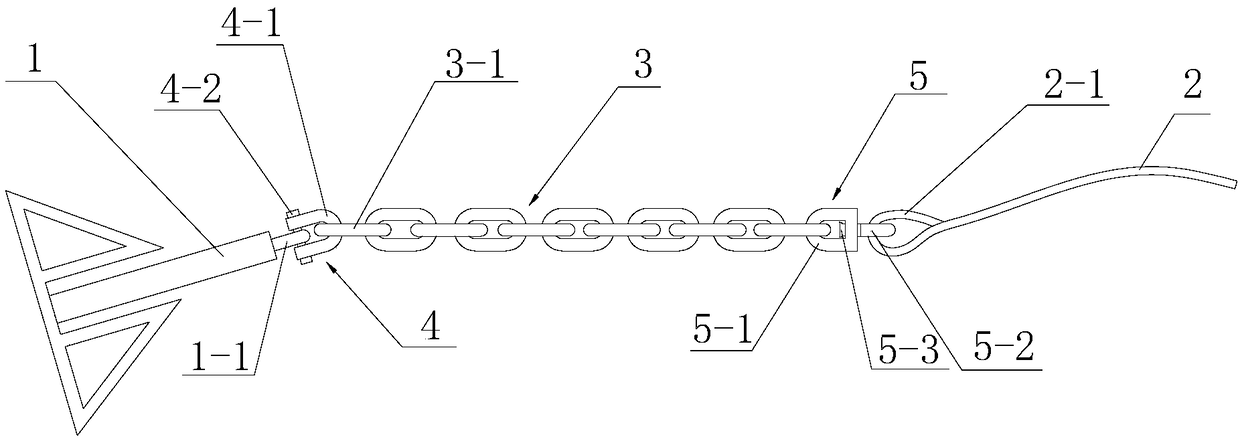

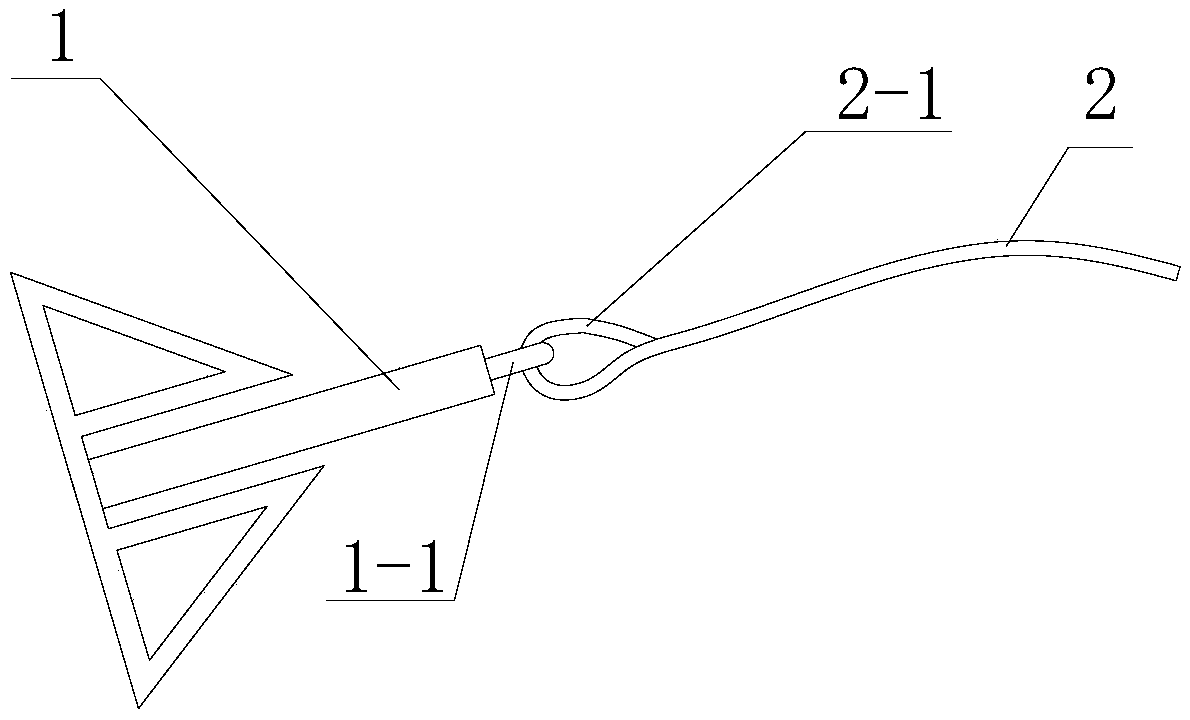

Anti-dragging device for transverse moving anchor of cutter suction dredger

PendingCN108824537AImprove gripAvoid distortionMechanical machines/dredgersGrip forceTransverse frictions

The invention relates to an anti-dragging device for a transverse moving anchor of a cutter suction dredger. The anti-dragging device comprises the transverse moving anchor and a transverse moving steel cable and is characterized in that the anti-dragging device further comprises a transverse moving anchor chain used for increasing the contact area and the transverse friction force with underwatersoil, one end of the transverse moving anchor chain is connected with an anchor column connecting ring of the transverse moving anchor through a first connecting ring, and the other end of the transverse moving anchor chain is connected with a lock catch arranged at the end of the transverse moving steel cable through a second connecting ring. By adopting the brand-new technical scheme, comparedwith the prior art, the ground gripping force of the transverse moving anchor can be effectively increased, cable distortion is prevented, the positive effect on transverse moving construction of a crane span structure of the cutter suction dredger is achieved, and the anti-dragging device is suitable for cutter suction dredger construction. In addition, the anti-dragging device further has the advantages of being simple in structure, convenient to use and the like.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

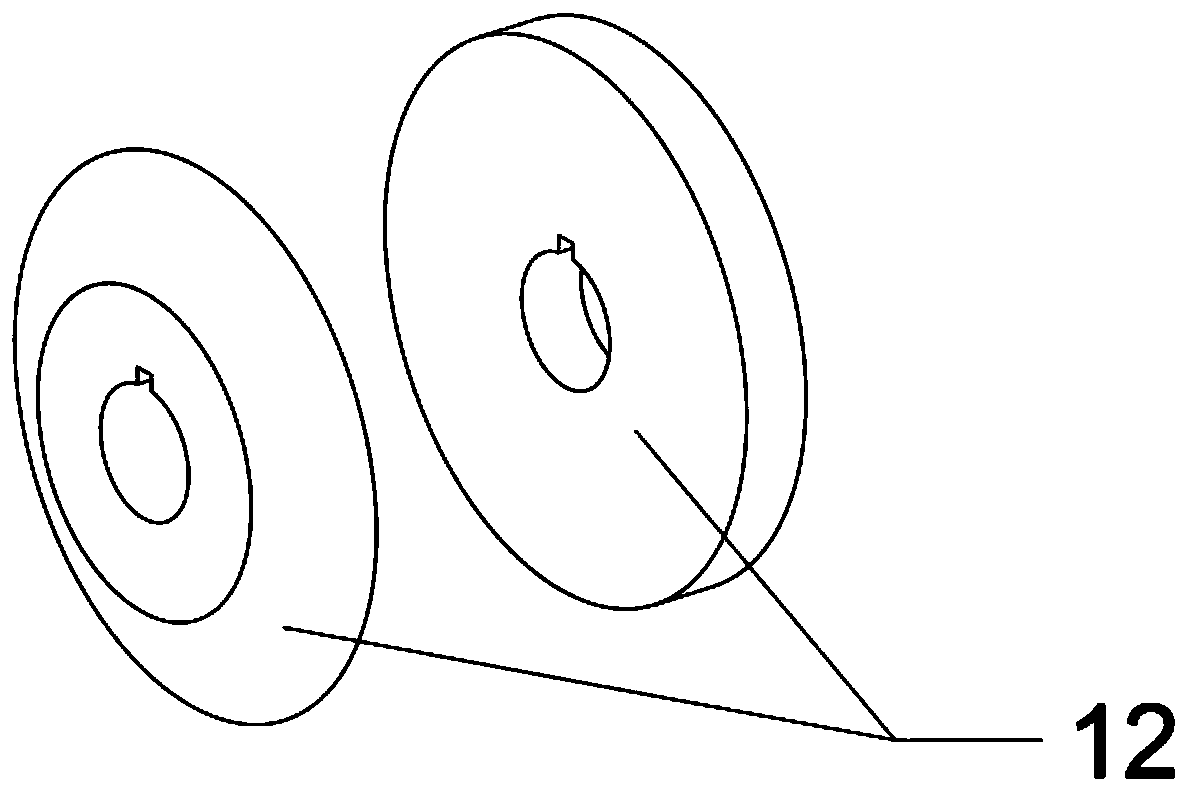

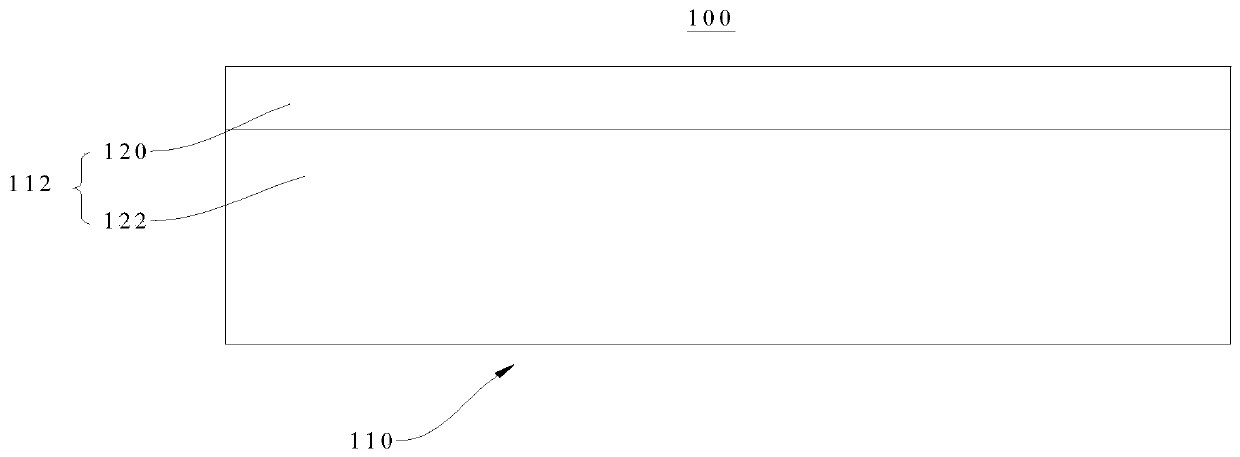

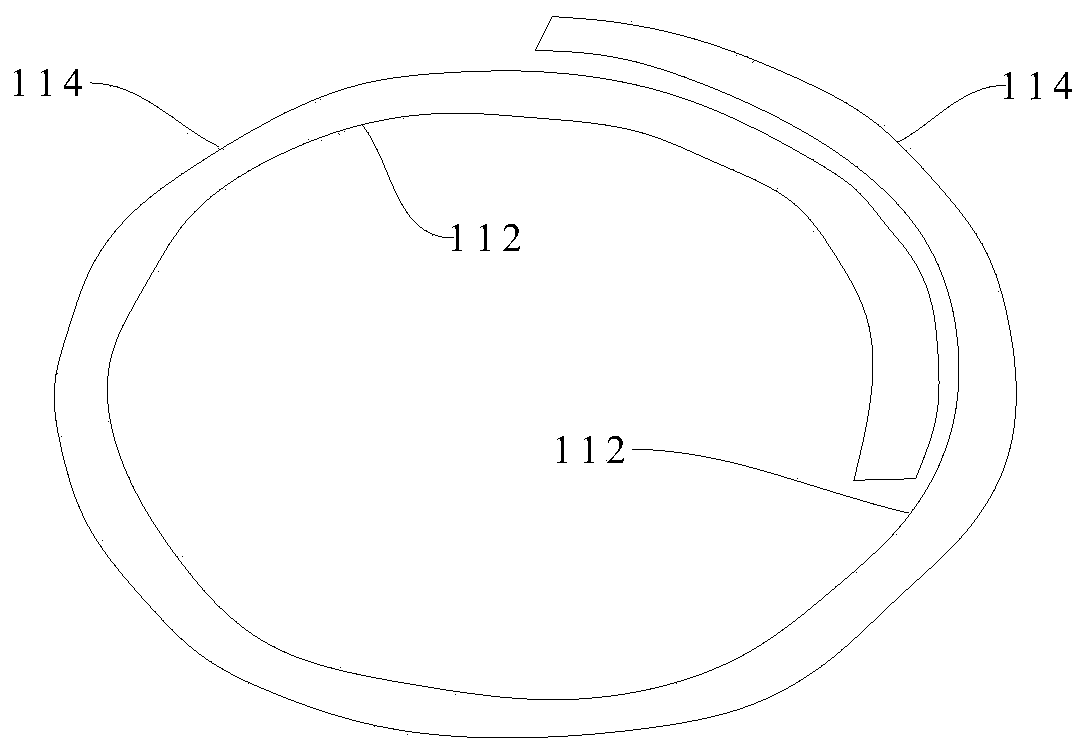

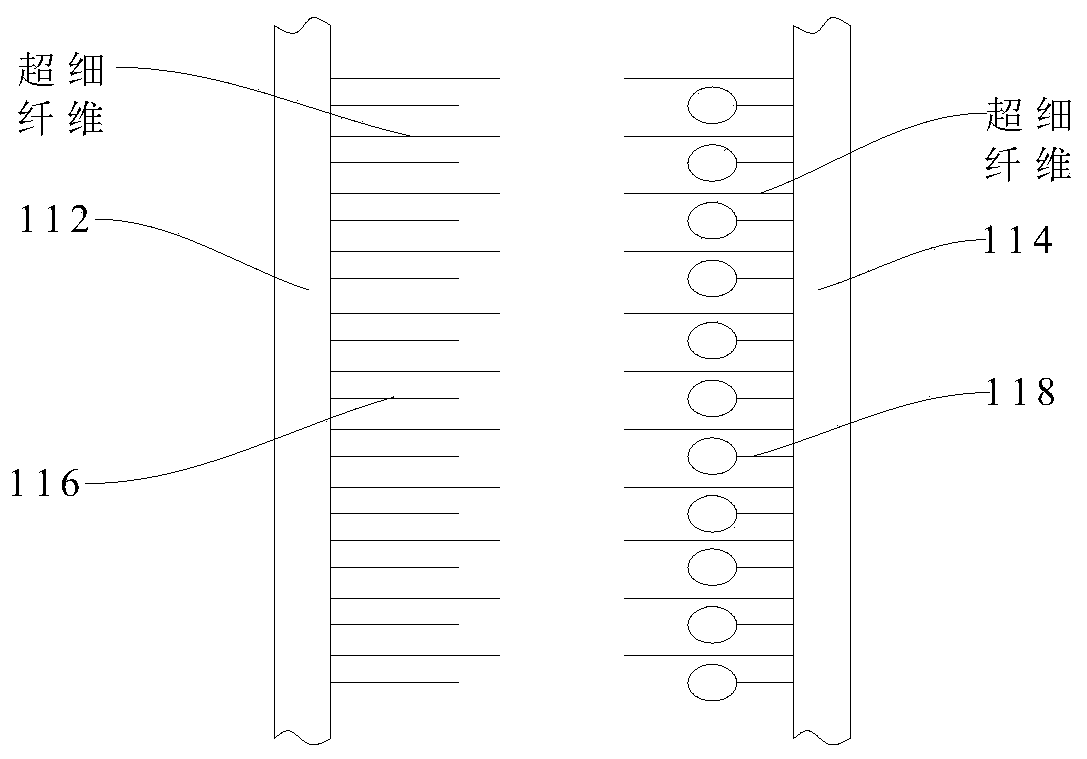

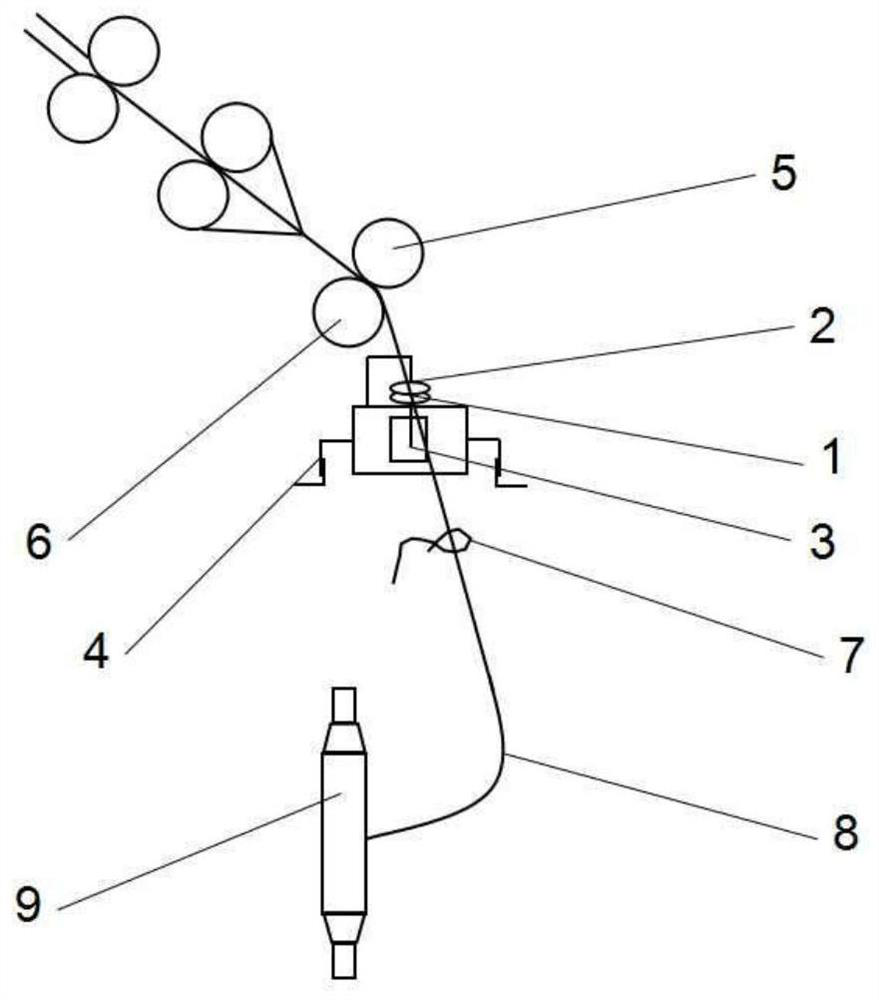

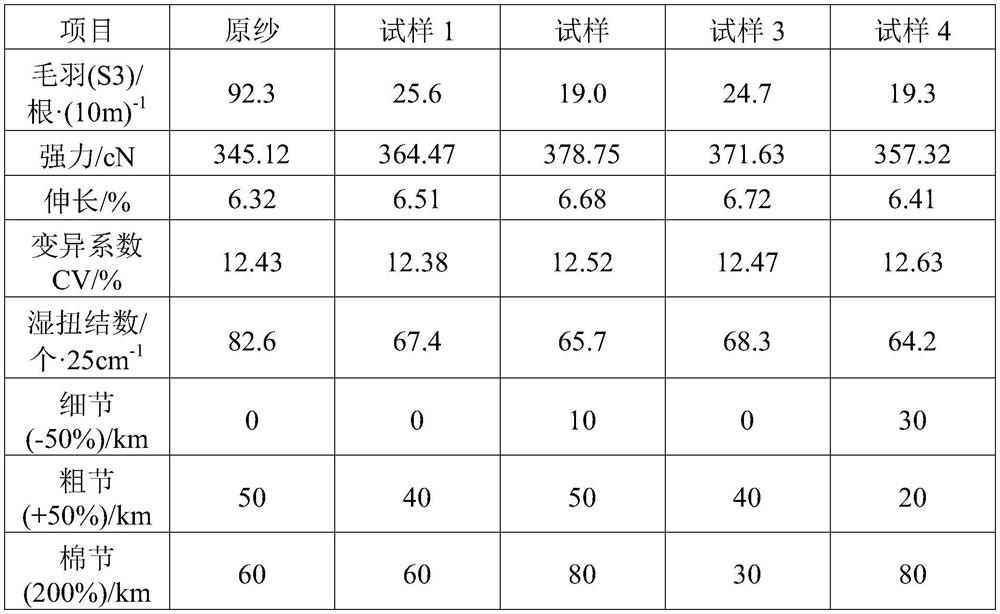

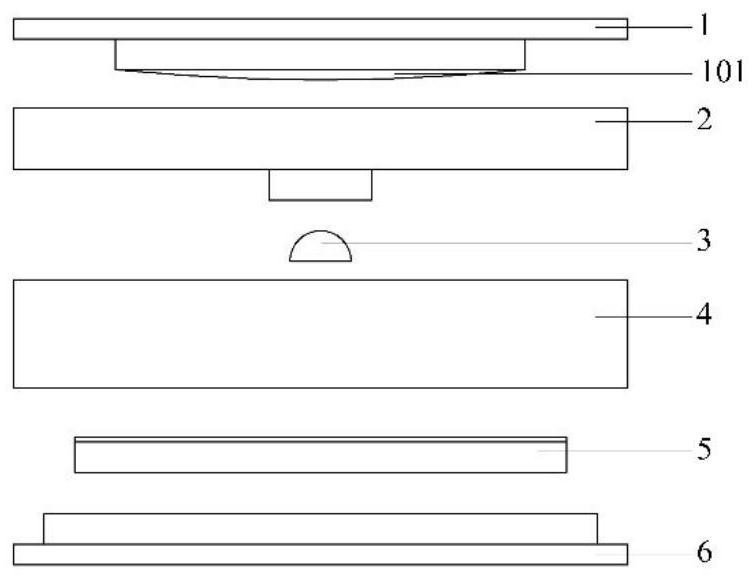

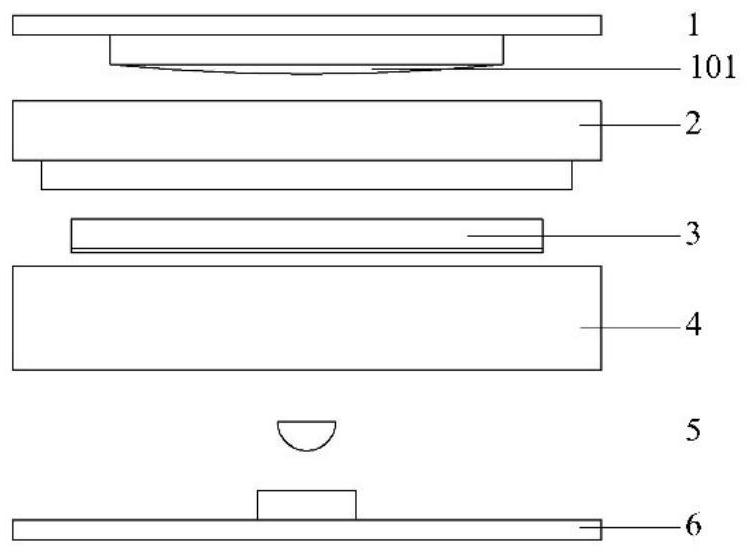

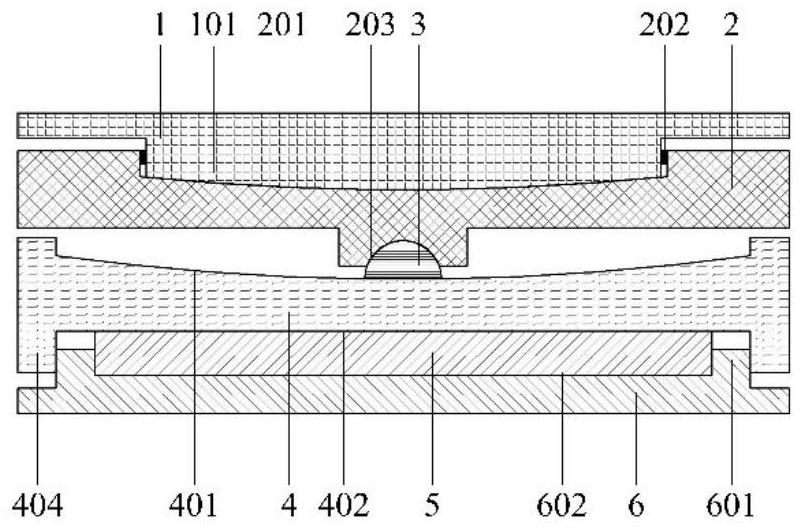

Spinning method capable of adaptively regulating yarn structure and false twisting device

PendingCN112877823ATorque balanceImprove straightening parallelismContinuous wound-up machinesYarnFiber

The invention relates to a spinning method capable of adaptively regulating and controlling a yarn structure and a false twisting device, and belongs to the technical field of spinning processing. An electromechanical device is mainly adopted to drive a rotating device to run at a high speed, and a tension device regulates a contact behavior and restrains yarn movement by means of self weight; during spinning, yarns pass through a gap between the rotating device and the tension device; and the transverse friction force generated by high-speed rotation of the rotating device regulates and controls the fiber arrangement structure and heats the yarn at the same time, so that the fiber modulus is reduced, and the fibers are fully transferred. The false twisting device is simple and reasonable in structure and high in production efficiency, and the spun yarn has the advantages that the hand feeling is soft, the strength is improved, hairiness is obviously reduced, and the evenness is stable.

Owner:WUHAN TEXTILE UNIV

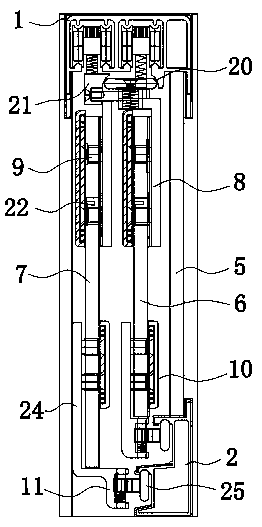

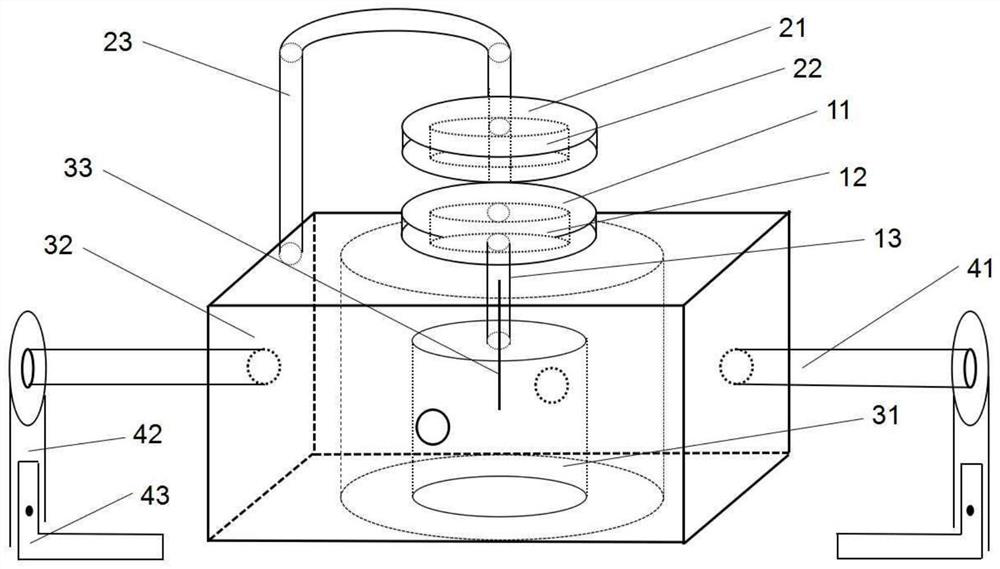

Separated friction support with adjustable horizontal bidirectional mechanical parameters

ActiveCN114319601ASimplify the Seismic Design ProcessMeet the requirements of different mechanical propertiesBridge structural detailsProtective buildings/sheltersTransverse frictionsMechanical engineering

The invention discloses a separated friction support with adjustable horizontal two-way mechanical parameters. The support comprises a rotating plate, a longitudinal translation plate, a longitudinal friction cylinder, a two-way translation plate, a transverse friction cylinder and a fixed plate from top to bottom. Wherein a spherical crown body at the lower part of the rotating plate is attached to a concave surface at the upper part of the longitudinal translation plate to form a pair of rotating friction surfaces so as to bear the rotation of the support in a horizontal plane; the longitudinal translation plate, the longitudinal friction cylinder and the bidirectional translation plate are overlapped to form two pairs of sliding friction surfaces so as to bear the translation of the support along the horizontal longitudinal direction; the bidirectional translation plate, the transverse friction column body and the fixing plate are overlapped to form two pairs of sliding friction surfaces so as to bear translation of the support in the horizontal transverse direction. Compared with the prior art, the horizontal deformation of the support is decomposed into translation and rotation in the two vertical directions in the plane, the friction surfaces in the two horizontal directions can be designed respectively, so that different requirements of mechanical properties in the two directions are met, and meanwhile, the energy dissipation capacity of the support under the action of earthquakes and the like is improved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com