Batch chamfering clamp of acousto-optic crystal blocks

A crystal block and acousto-optic technology, which is applied in the core material processing field of the acousto-optic tunable filter, can solve the problems of low efficiency, poor processing uniformity, cumbersome process, etc., achieve good chamfering uniformity, improve yield, The effect of reducing cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

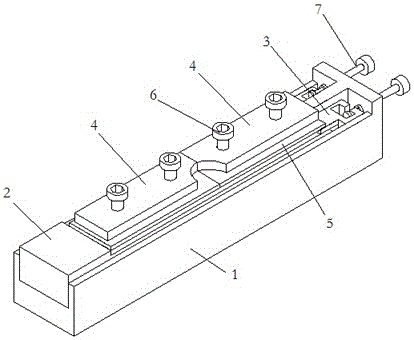

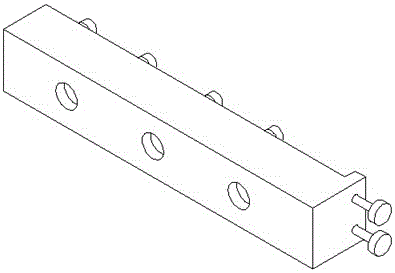

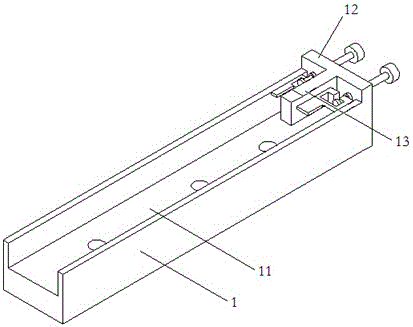

[0025] see figure 1 and figure 2 , as can be seen from the figure, the batch chamfering fixture of the acousto-optic crystal block of the present invention includes an outer frame 1, a positioning block 2, an end baffle 3, a pressing plate 4 and a rubber pad 5, and the upper surface of the outer frame 1 has a The installation groove 11 , the positioning block 2 is fixedly installed in the installation groove 11 and protrudes from the installation groove 11 . see also Figure 4 The upper surface of the positioning block 2 is formed with a T-shaped convex structure consisting of an end protrusion 21 and a central protrusion 22, and the areas on both sides of the central protrusion 22 on the upper surface of the positioning block 2 form a crystal block for placing the crystal block. In the block placement area 23, the height of the T-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com