Rotating type friction energy dissipation wall

A technology of friction energy consumption and friction plate, which is applied in the field of shock absorption control of building structures, can solve problems such as output force drop, secondary material wear, and residual deformation of friction dampers, so as to prevent changes in friction coefficient and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

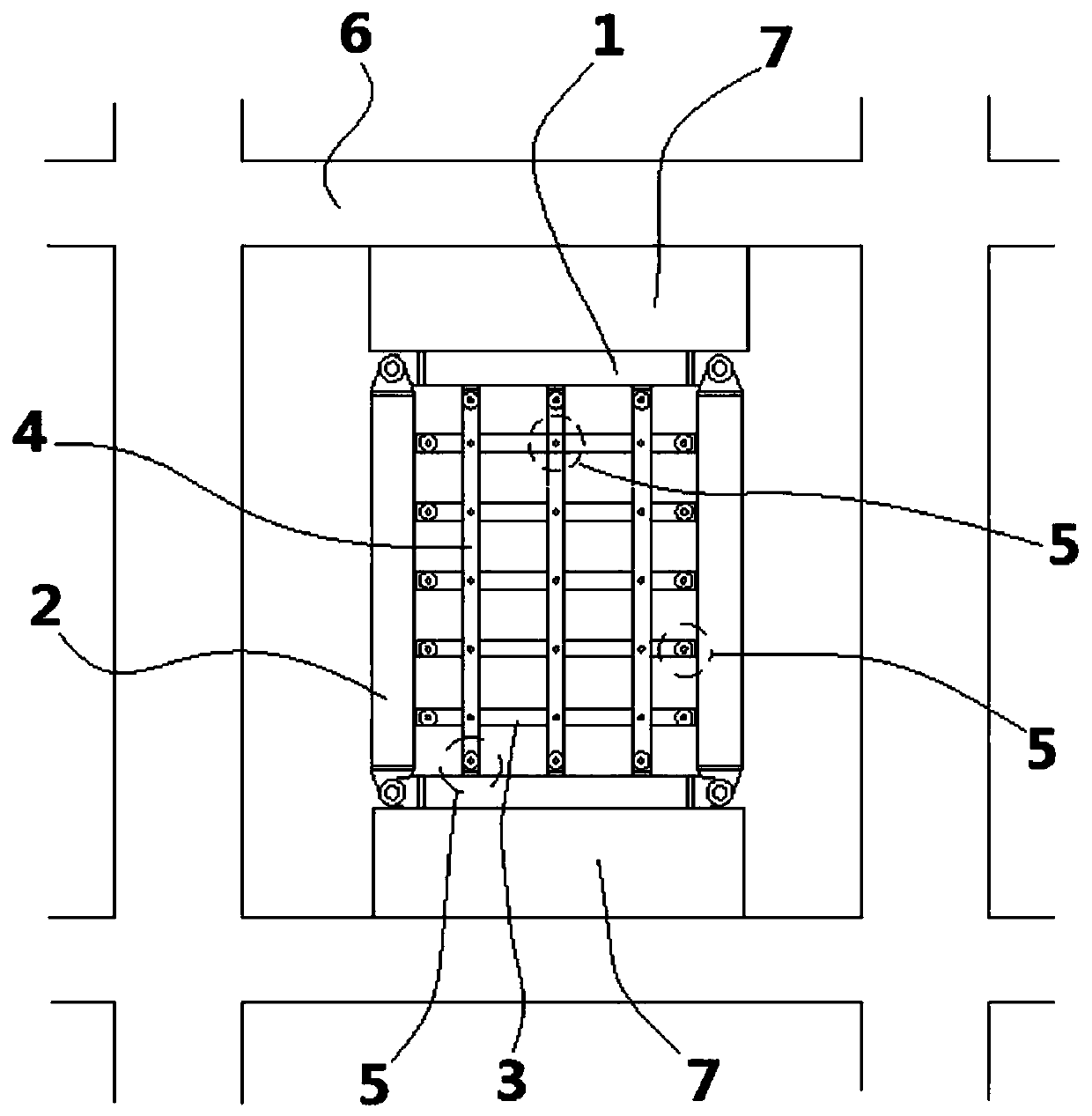

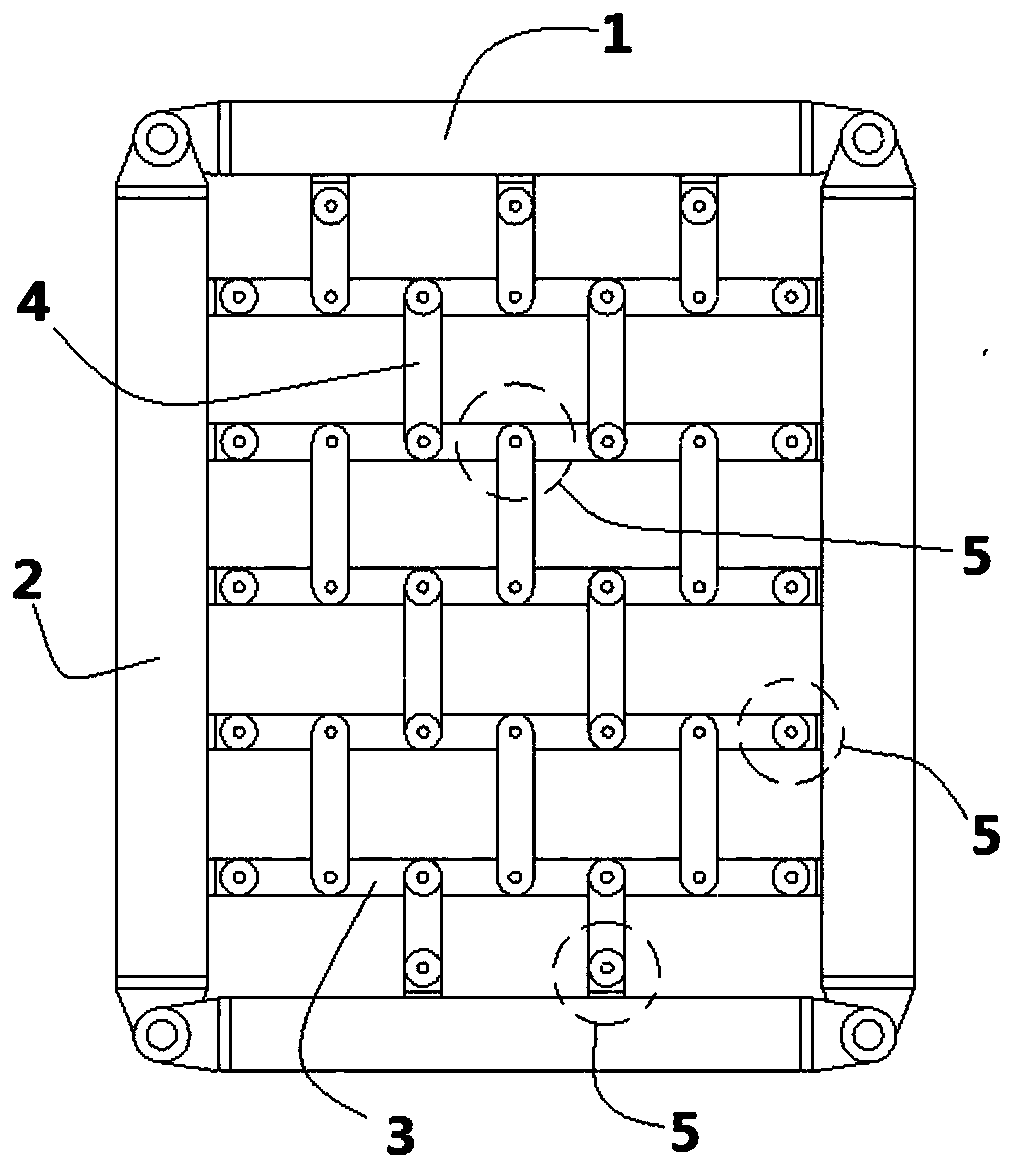

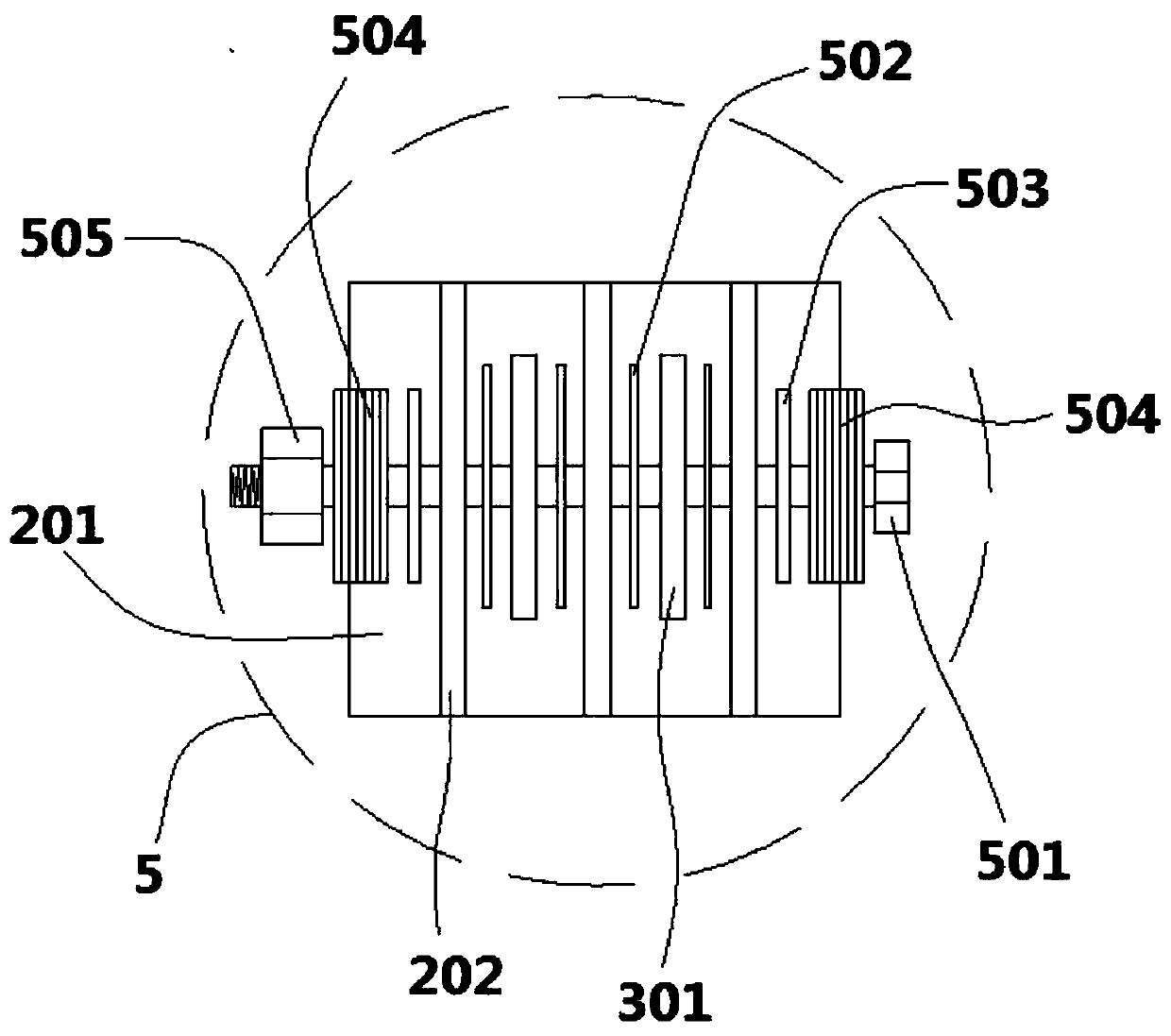

[0035]This embodiment discloses a rotating frictional energy-dissipating wall, including horizontal outsourcing steel 1 , vertical outsourcing steel 2 , several horizontal friction steel plate groups 3 , several longitudinal friction steel plate groups 4 , several friction nodes 5 and a building frame structure 6 . The cross-sections of the transverse outsourcing section steel 1 and the longitudinal outsourcing section steel 2 are I-shaped or H-shaped, and both ends of the transverse outsourcing section steel 1 and the longitudinal outsourcing section steel 2 are connected with hinges, and the two transverse outsourcing section steel 1 and Two longitudinal outsourcing shaped steels 2 are hinged to each other to form a rectangular frame, and the two transverse outsourcing shaped steels 1 are respectively connected to the upper beam and the lower beam of the building frame structure 6 .

[0036] A number of welded steel plates I101 are arranged on the opposite plate surfaces of t...

Embodiment 2

[0048] This embodiment discloses a rotating frictional energy-dissipating wall, including horizontal outsourcing steel 1, vertical outsourcing steel 2, several horizontal friction steel plate groups 3, several longitudinal friction steel plate groups 4, several friction nodes 5, building frame structure 6 and steel plates 7. The cross-sections of the transverse outsourcing section steel 1 and the longitudinal outsourcing section steel 2 are I-shaped or H-shaped, and both ends of the transverse outsourcing section steel 1 and the longitudinal outsourcing section steel 2 are connected with hinges, and the two transverse outsourcing section steel 1 and Two longitudinal outsourcing steel sections 2 are hinged to each other to form a rectangular frame. see figure 1 A steel plate 7 is connected between one of the transverse outsourcing steel 1 and the upper beam of the building frame structure 6 , and a steel plate 7 is connected between the other horizontal outsourcing steel 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com