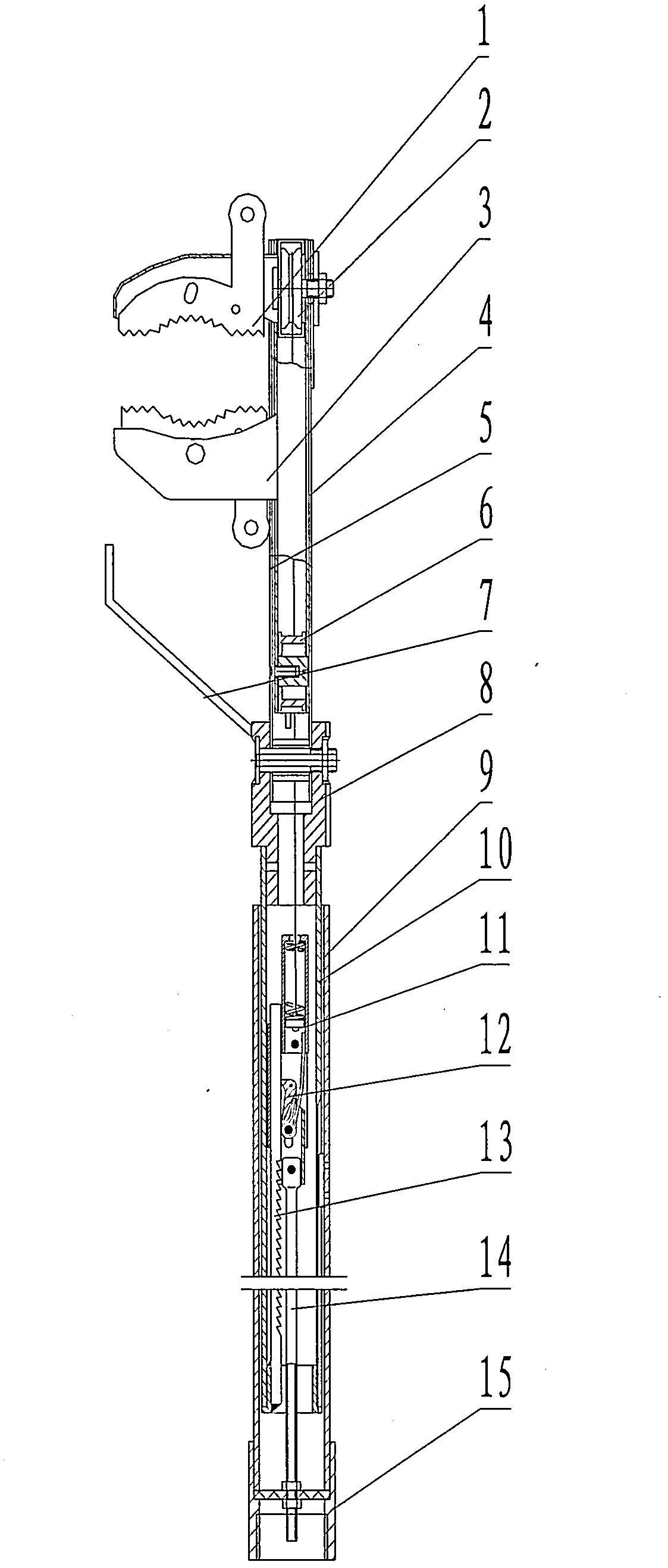

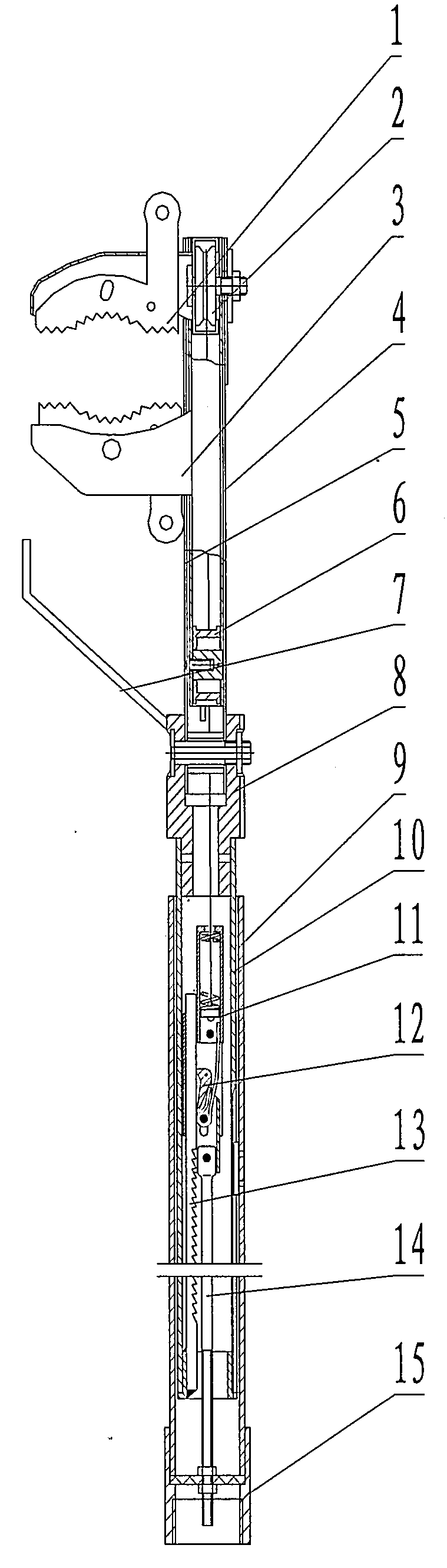

Multi-angle operating rod

An operation stick and multi-angle technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of extended working hours, unsafe equipment and personnel, low efficiency, etc., and achieve the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] With reference to accompanying drawing, when operating the present invention, rotating connector 15 makes it move by push-pull bar, steel wire rope and drives the upper pulley action of rotating bracket 4, and moving jaw approaches to fixed jaw thereupon, makes fixed and moving jaw clamp lead. The push-pull mechanism is equipped with a locking mechanism to ensure the clamping force of the jaws. The installation holes of the fixed and movable jaws are obliquely long, so that lateral frictional movement occurs while the jaws are clamped to overcome the oxide film at the wiring position. Thereby protecting the electrical conductivity.

[0009] In addition to the above-mentioned embodiments, the present invention can also have other embodiments. All technical solutions in the form of equivalent replacement or equivalent transformation fall within the scope of protection required by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com