Grinding device for burr of aluminum end ring of cast aluminum rotor

A technology for cast aluminum rotors and end rings, which is applied in the direction of grinding drive devices, grinding machines, grinding workpiece supports, etc., and can solve problems such as the safety impact of hand-held rotor grinding methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

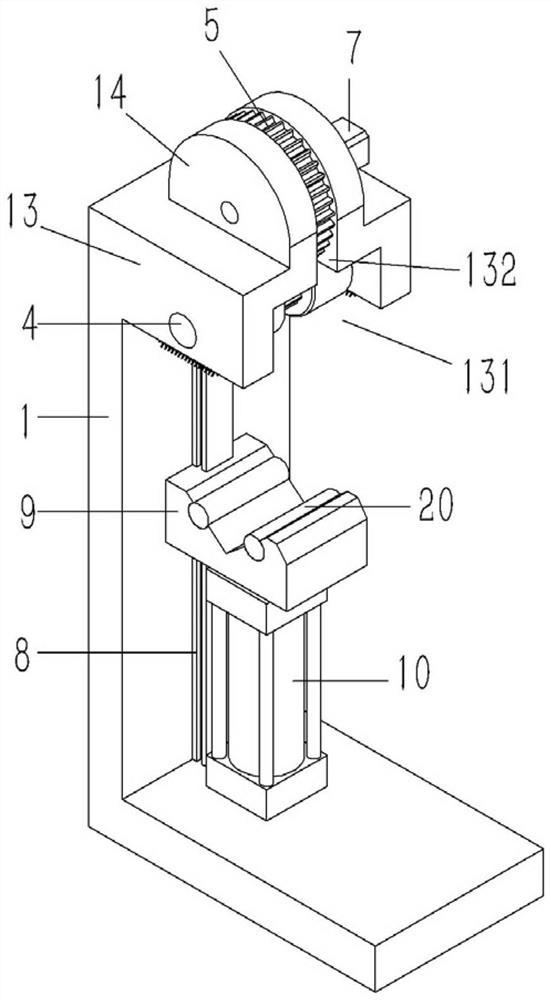

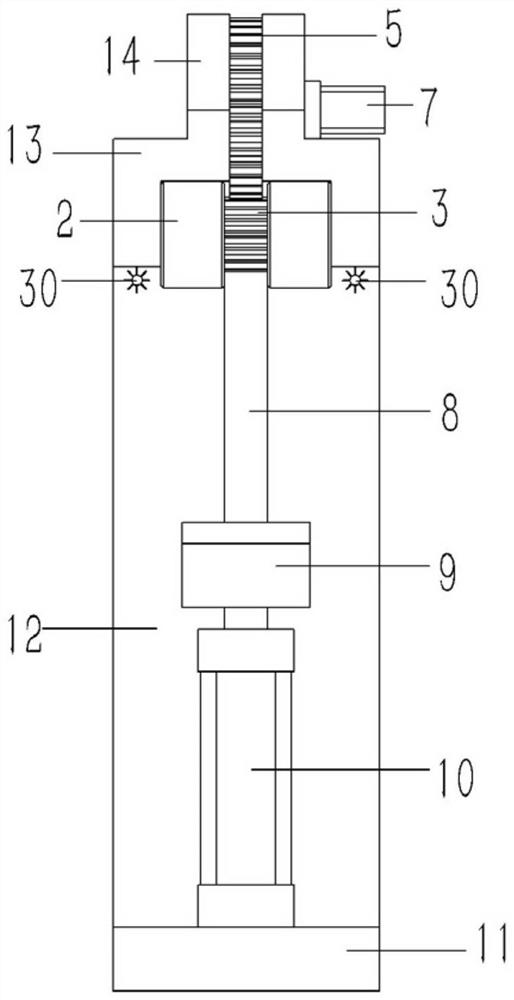

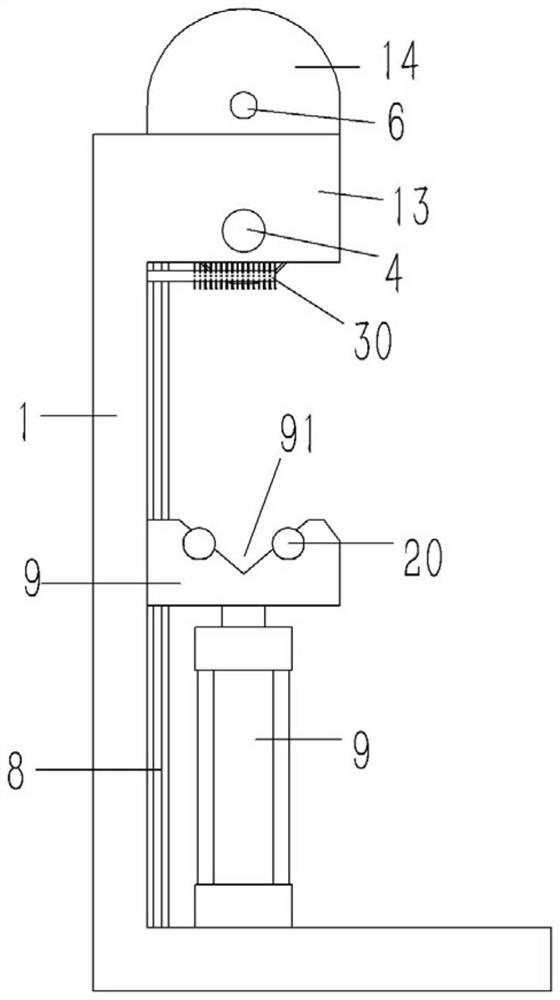

[0018] Example: see Figures 1 to 3 As shown, a grinding device for the aluminum end ring burr of a cast aluminum rotor includes an L-shaped machine base 1, the machine base 1 includes a bottom plate 11 and a vertical support plate 12 at the rear end of the bottom plate 11, and the upper end of the support plate 12 is formed with Rectangular grinding seat 13, the lower end surface of the grinding seat 13 is formed with a slot 131 that runs through the front end face of the grinding seat 13, and two transverse friction wheels 2 are inserted in the slot 131 of the grinding seat 13. The lower end of the wheel 2 exposes the lower end surface of the grinding seat 13; a transmission gear 3 is interposed between the friction wheels 2, and the transmission gear 3 and the friction wheel 2 are all inserted and fixed on the coupling shaft 4, and the two coupling shafts 4 The end is hinged on the grinding seat 13 through a bearing; the upper end surface of the grinding seat 13 directly ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com