Bath towel and production technology thereof

A production process and technology of bath towels, applied in the field of bath towels and its production, can solve problems such as easy slippage of bath towels, and achieve the effects of long service life, high production efficiency, and enhanced bonding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a production process for bath towels, which mainly includes the following steps:

[0032] Prepare microfibers with a diameter less than or equal to 5 microns, which include nylon and polyester in a mass ratio of 1:4. More than 200 superfine fibers are then woven into yarn, and then the yarn is woven into terry cloth. The woven terry cloth continues to be rinsed, dyed, rinsed, drained, and set at high temperature.

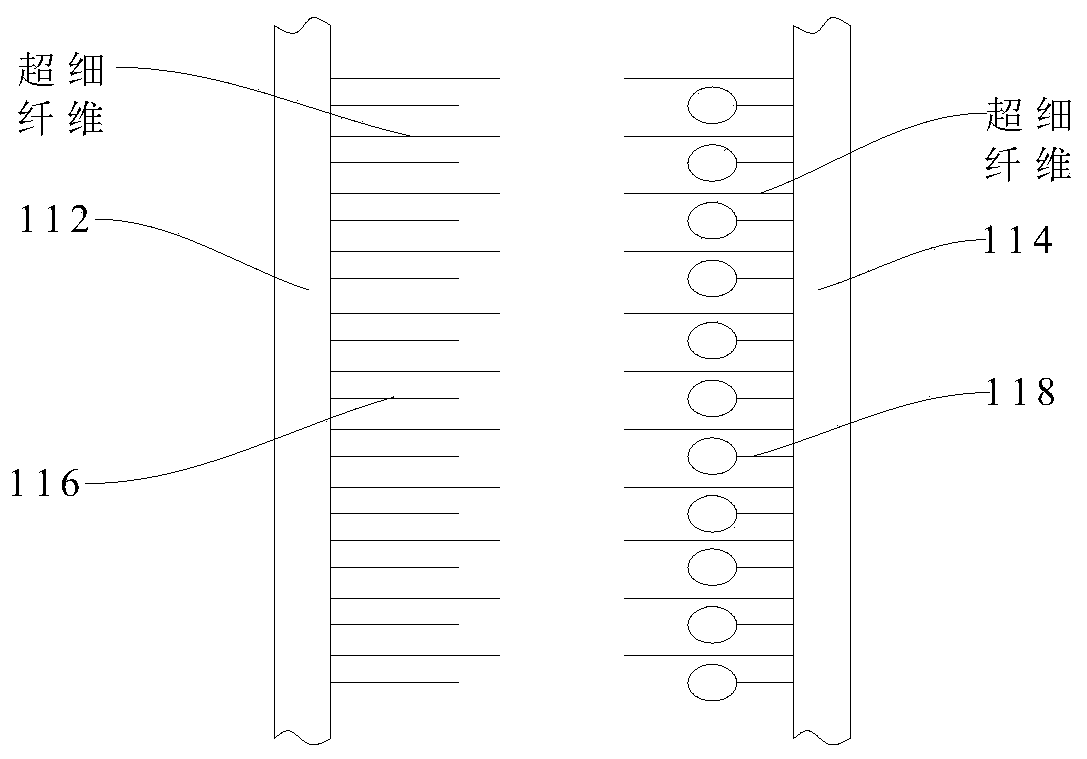

[0033] The first fleece is woven into loops by the weave method of sheared fleece, and the loops are cut off after setting the shape to obtain the needle-shaped first bonded fleece. After weaving the loops, it is produced through scouring, washing, dyeing, drying, grasping, shaping and other processes, and then the 1mm long loops are cut off by a high-precision shearing machine imported from Germany to produce needle fleece (that is, the first flannel). The second flannelette adopts the VISA fabric weaving method to weave umbrella-...

Embodiment 2

[0036] This embodiment provides a production process for bath towels, which differs from the production process provided in Example 1 in that it also includes the following steps:

[0037]After the terry cloth is produced, the terry cloth is cut into 3 areas, including the first arm area, the main body area and the second arm area connected in sequence. One end of the first arm area is fixedly connected with the main body area, and the other end is detachably connected with the main body area. One end of the second arm area is fixedly connected with the main body area, and the other end is detachably connected with the main body area. A plurality of (at least 2) first pressing sheets are arranged at one end of the main body area close to the first arm area, the two ends of the first pressing sheets penetrate the main body area, and after the two ends of the first pressing sheets are bent, the first pressing The sheet fits snugly on the body area. The end of the first arm reg...

Embodiment 3

[0040] This embodiment provides a bath towel 100, which is mainly produced by the production process of the embodiment *.

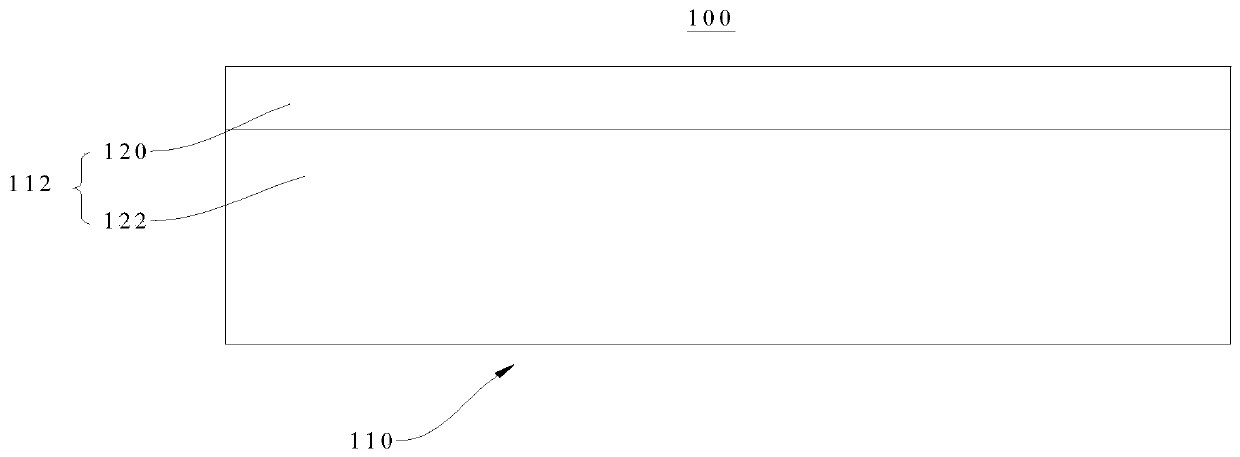

[0041] Please refer to figure 1 , figure 1 Shown is a schematic view of the structure of the bath towel 100 . The function of the bath towel 100 is basically the same as that of the traditional bath towel. It can be used for wiping or wrapping the body after bathing.

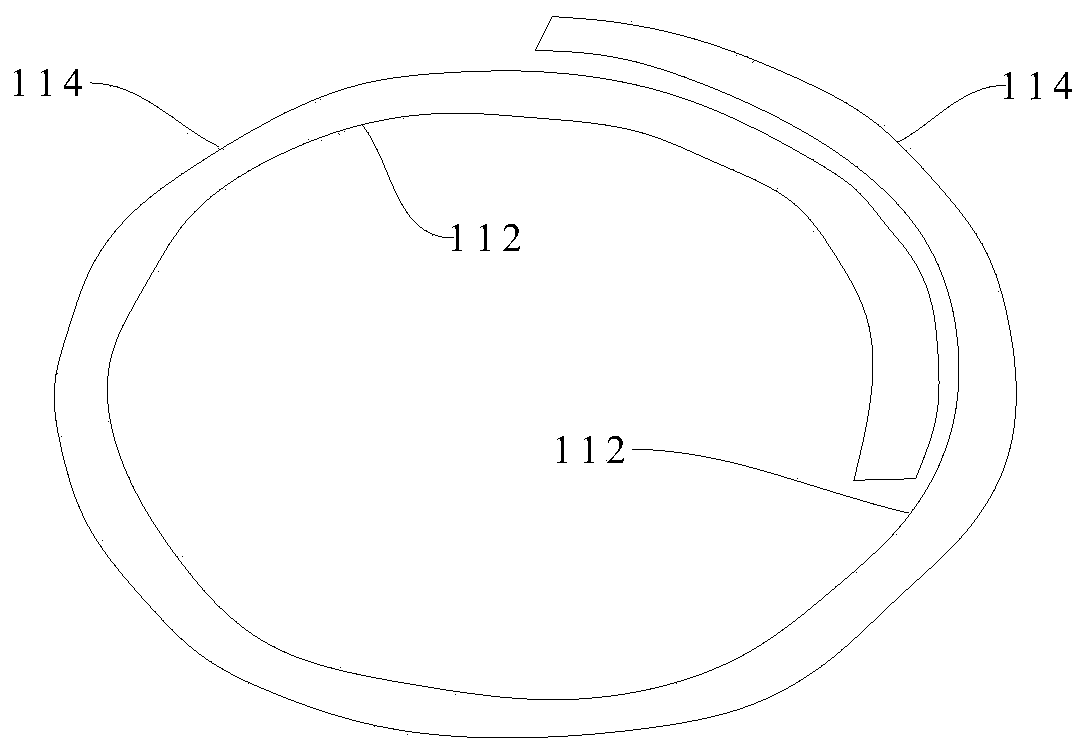

[0042] The bath towel 100 mainly includes a bath towel body 110 . Please refer to figure 1 , figure 2 and image 3 , figure 2 Shown is a schematic structural view of the bath towel 100 after it is wound, image 3 Shown is a schematic diagram of the adhesive mating of the two sides of the bath towel 100 . The bath towel body 110 includes a first side 112 and a second side 114 oppositely arranged, figure 1 Shown in is the first side 112 . The first side 112 is provided with a first bonding fleece 116 , and the second side 114 is provided with a second bonding fleece 118 that match...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com