Belt deflection correcting device

A correction device and deviation technology, applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of corrector failure, difficult to clean, rust and other problems, and achieve improved reliability of performance, improved bottom space, The effect of the compact structure of the whole machine

Inactive Publication Date: 2011-06-15

山西潞安集团司马煤业有限公司 +1

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the height from the lower belt of the belt conveyor to the ground is relatively small, and the height from the lower edge of the rollers to the ground is even smaller, resulting in less than 100 mm of remaining space between the fixed beam and the belt conveyor installation foundation plane, which is easily destroyed by coal and coal falling off the belt. Buried in mud, the rollers are inflexible in rotation, and the swing beam of the corrector is blocked or even invalid. In addition, the rotating shaft on the upper swing beam and the shaft seat on the lower fixed beam will rust to death after being soaked in coal slime for a long time, resulting in the failure of the corrector. Difficult to clean

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

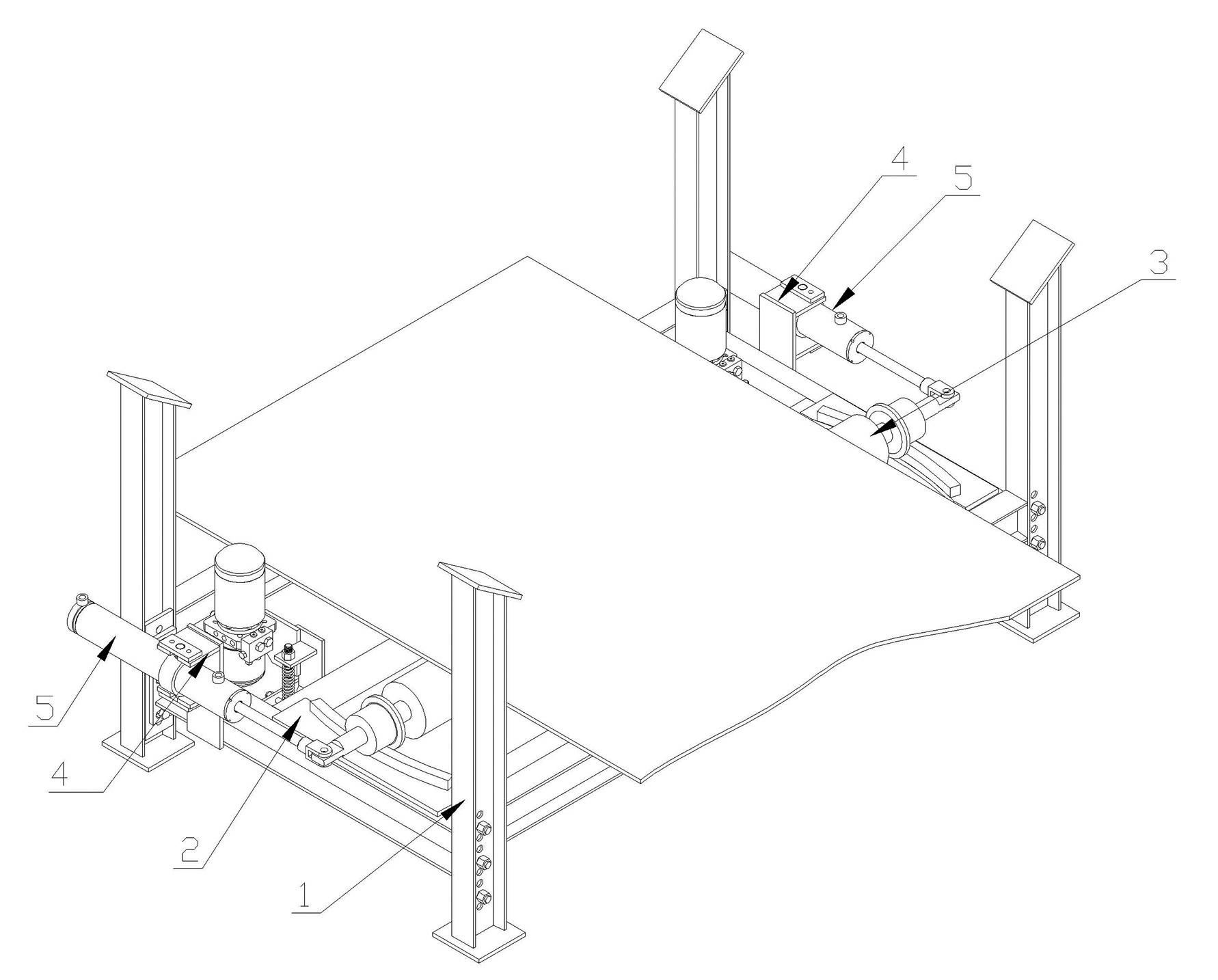

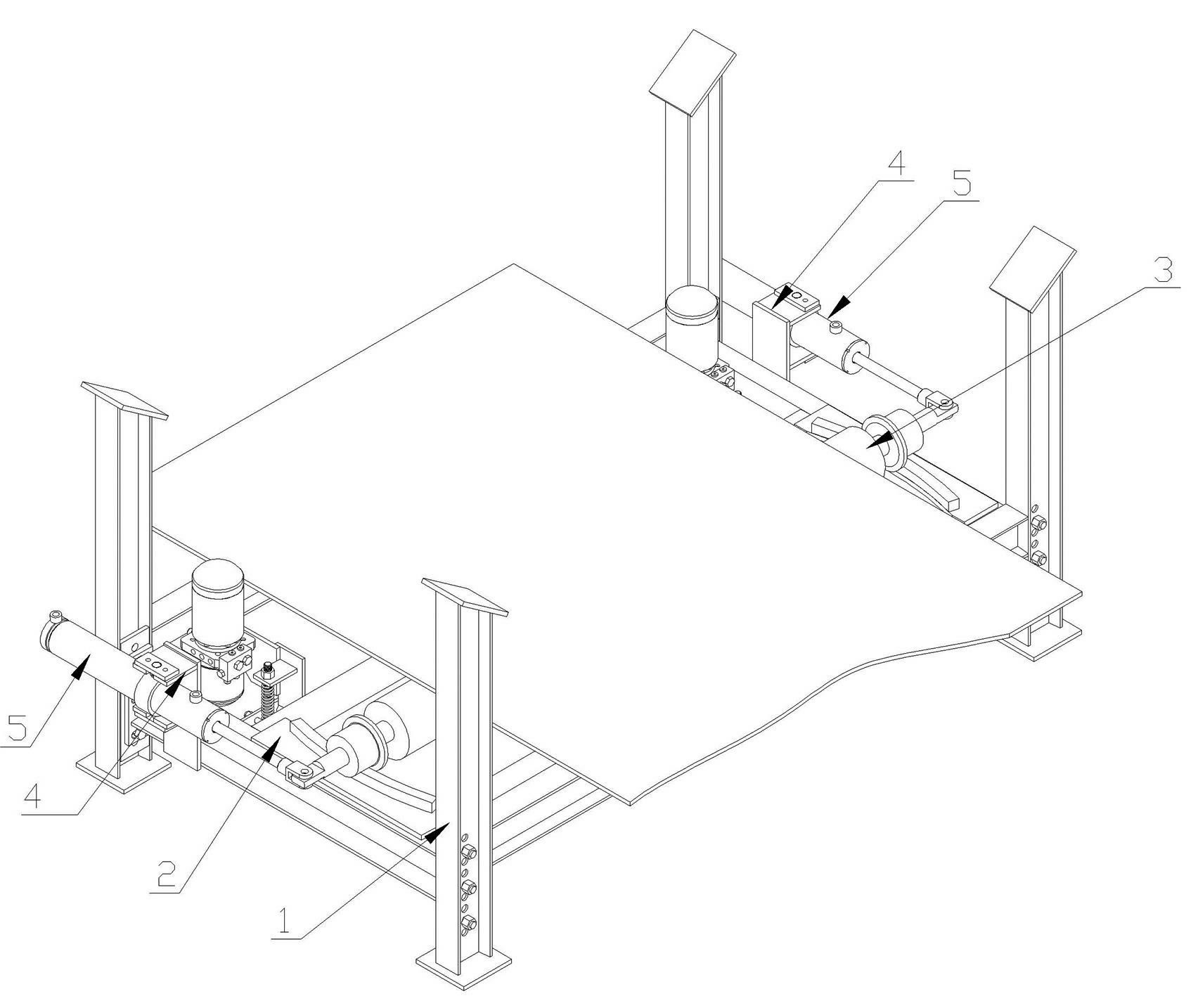

The invention discloses a belt deflection correcting device. The device comprises supporting legs, a fixing bracket, and an aligning roller, a driving detection device and oil cylinders which are arranged on the fixing bracket, wherein the fixing bracket is a horizontal beam bridged on the supporting legs; the upper parts of the two ends of the fixing bracket are provided with an arc-shaped track respectively; the two arc-shaped tracks are concentric with each other; roller wheels at two ends of the aligning roller are embedded with the arc-shaped tracks; and the two ends of the aligning roller are hinged with oil cylinder piston rods on the fixing bracket. The device has a larger bottom space, a compact structure and greatly improved performance reliability and is convenient to mount. When a belt is deviated toward one side, the side edge of the belt touches the driving detection device and drives an oil pump to work, so that the oil cylinder piston rod on one side is extended, and the oil cylinder piston rod on the other side is retracted at the same time; the oil cylinders on the two sides perform reverse motion synchronously to drive the aligning roller to rotate; and transverse friction force is generated depending on a deflection angle formed between the rotating direction of the aligning roller and the advancing direction of the belt so as to finally realize a deflection correction function.

Description

A belt deviation correction device technical field The invention relates to a mine belt conveyor, in particular to a deviation correction device for a mine belt conveyor. Background technique With the continuous development of science and technology, the mechanization level of coal mines has been continuously improved. The history of transporting coal to the outside of the mine by manpower in the past has long since disappeared. Now almost all belt conveyors are used as the main tool for transporting coal. During the working process, the belt conveyor is affected by various factors such as uneven load, belt adhesion and belt thickness difference. Vertical idler axis. After the deviation, the side of the belt will rub against the adjacent objects, increasing the load on the motor, which not only affects the normal transportation, but also easily damages the equipment, which brings potential safety hazards. At present, almost all kinds of belt conveyors are equipped with d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65G15/64B65G39/16

Inventor 谢国龙张立新闫玉晋付晓平陈来平

Owner 山西潞安集团司马煤业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com