Device for increasing transverse friction of template for manufacturing precast concrete

A concrete prefabrication and friction technology, applied in the direction of manufacturing tools, mold auxiliary parts, auxiliary molding equipment, etc., can solve the problems of increased error of concrete prefabricated parts, movement of side molds, poor positioning effect of side molds, etc., to reduce work The effect of reducing the amount of pulp, preventing slurry leakage and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

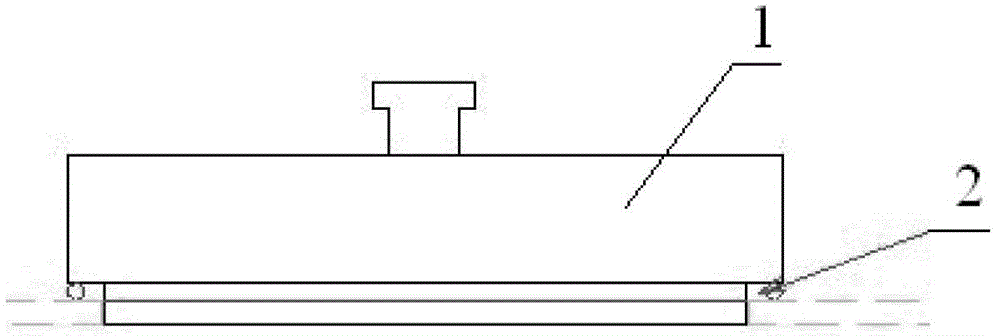

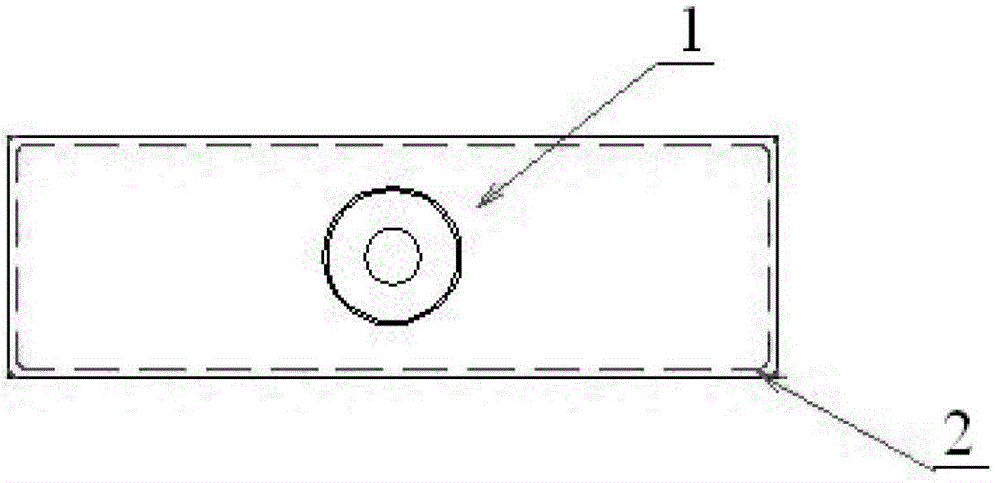

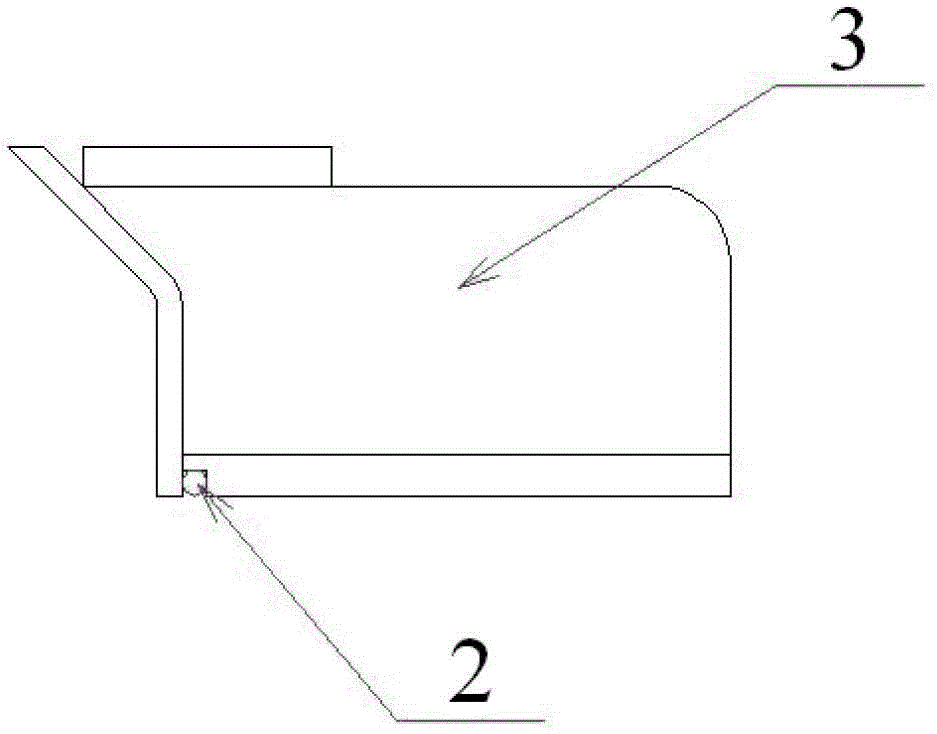

[0021] A device for increasing the lateral friction force of the concrete prefabricated formwork, its structure is as follows Figure 1-2 As shown, the device is used to fix the side mold 3, including a magnet 1 and a rubber strip 2, the magnet 1 is fixed on the side mold 3, the outer ring of the magnet 1 is provided with a groove, and the rubber strip 2 is arranged in the groove, increasing the The friction between the magnet and the side form prevents the side form from sliding. In addition, the structure of the side mold 3 is as image 3 As shown, there is a groove at the bottom of the side mold 3, and a rubber strip 2 is arranged in the groove, which can also increase the friction between the magnet 1 and the side mold 3, prevent the side mold from sliding, and prevent leakage. pulp effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com