Spinning method capable of adaptively regulating yarn structure and false twisting device

A self-adaptive control and yarn technology, which is applied in the field of textile processing, can solve problems such as uneven pressure between the spinning section and the disc, inability to significantly reduce hairiness, and fiber whisker collision, etc. The effect of tightness and increased fiber cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

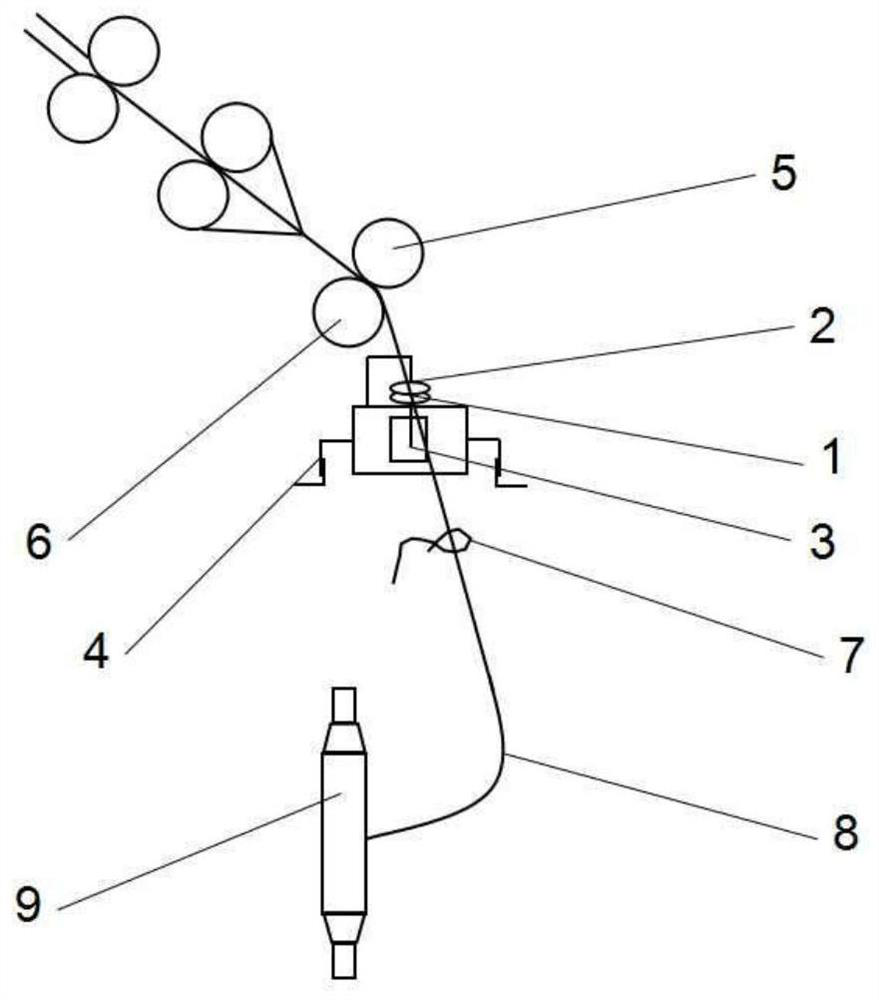

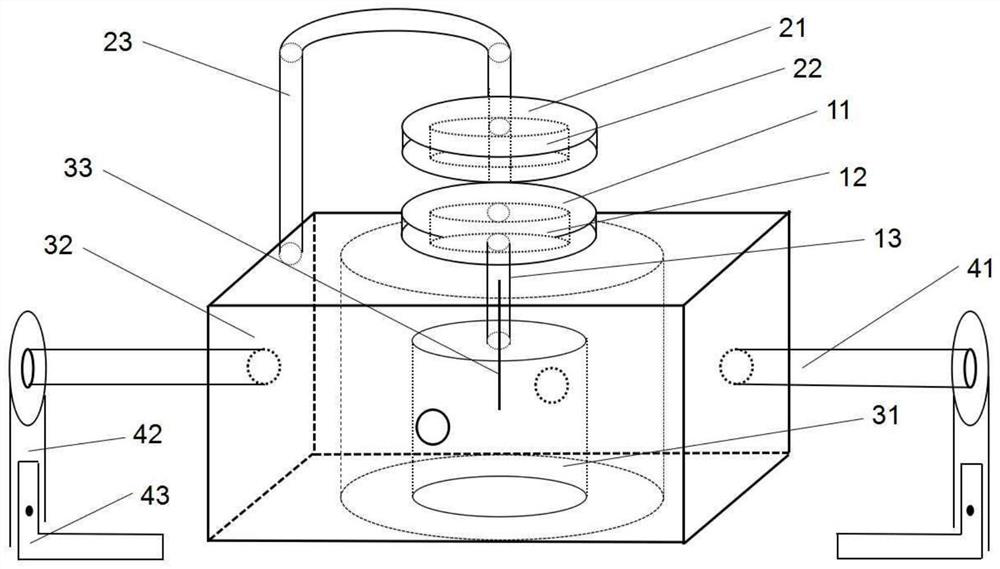

Method used

Image

Examples

specific Embodiment

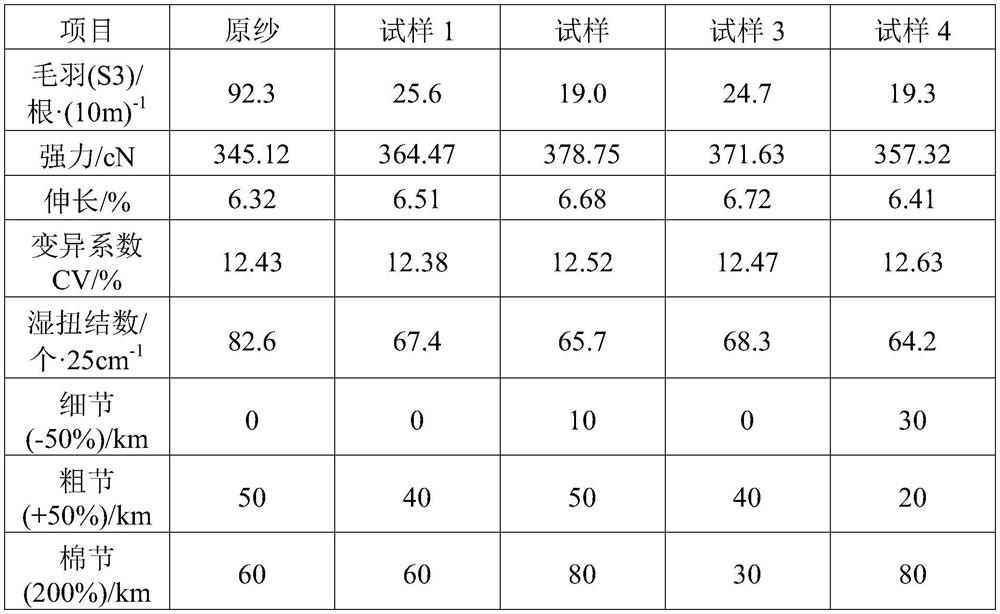

[0038] In this embodiment, the spinning device according to the present invention is used to produce 15tex yarn. The raw material used in the experiment is 100% pure cotton roving, the spindle speed of the ring spinning machine is 8000r / min, and the rotating disc speed is 500, 1000, 1500, 2000rpm / min (respectively samples 1 to 4) for spinning, wherein The rotation of the rotating disk is clockwise (consistent with the yarn movement direction), and the tension disk is driven by the rotating disk to rotate adaptively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com