Single-surface friction power generator based on transverse friction and preparation method of single-surface friction power generator

A surface friction and generator technology, applied in the direction of friction generators, processes for producing decorative surface effects, manufacturing of microstructure devices, etc., can solve problems such as unfavorable processing integration, and achieve easy integrated processing, simple process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

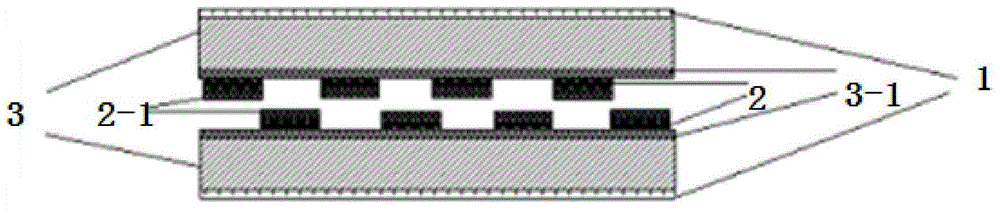

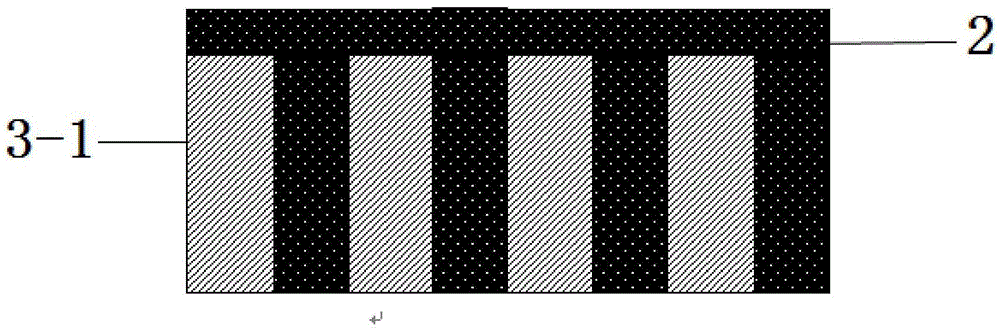

[0027] Example: such as Figure 1 to Figure 5 As shown, it includes a conductive layer 1, an aluminum electrode 2 with a grid structure, an aluminum electrode nanostructure layer 2-1, a PTFE film layer 3, and a film nanostructure layer 3-1. The preparation steps are as follows:

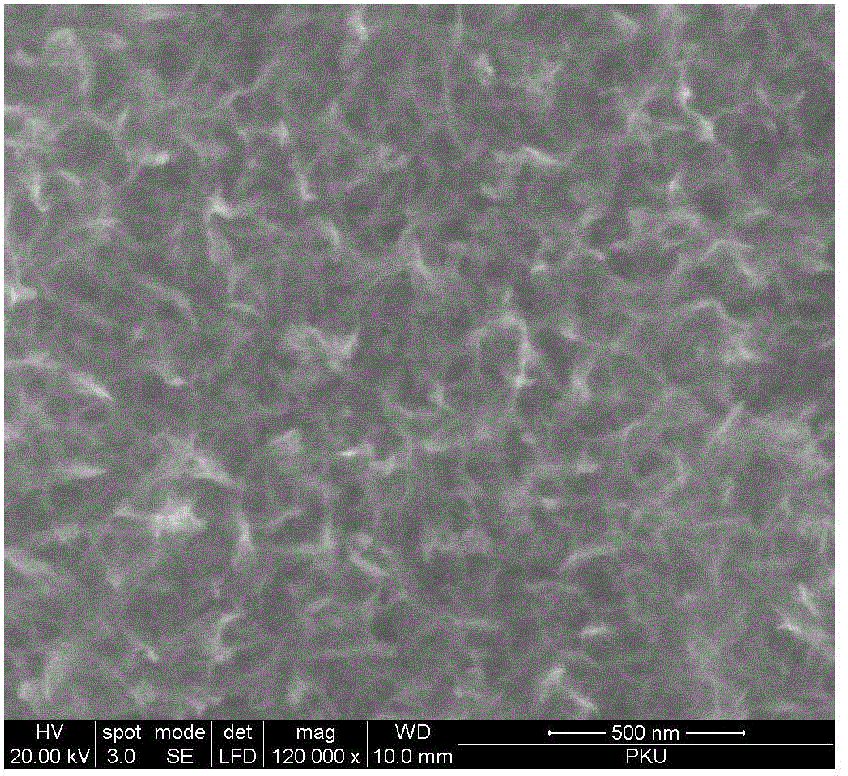

[0028] Step 1: using the positive plasma generated by the reactive ion etching process to bombard the surface of the PTFE film layer 3 to form an irregular thin film nanostructure layer 3-1 on one side of the PTFE film layer 3 .

[0029] Step 2: using sputtering or evaporation or a chemical vapor deposition process to form a complete aluminum electrode on the surface of the thin film nanostructure layer 3-1;

[0030] Step 3: using a photoresist mask to realize a patterned metal electrode by photolithography, so as to obtain an aluminum electrode 2 with a grid structure;

[0031] Step 4: Use water bath heating method to obtain aluminum electrode nanostructure layer 2-1 on the surface of aluminum elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com