Mg-XAl-YCa-ZZn alloy low in cost, high in performance and high in Ca/Al ratio and preparation method

A high-performance, low-cost technology, applied in the field of Mg-Ca-Al-Zn alloy with high Ca/Al ratio and its preparation, Mg-XAl-YCa-ZZn alloy and its preparation, can solve the problem of low strength and plasticity, cast magnesium Problems such as the decline in the mechanical properties of alloys, to achieve good mechanical properties, improve yield strength, and increase plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

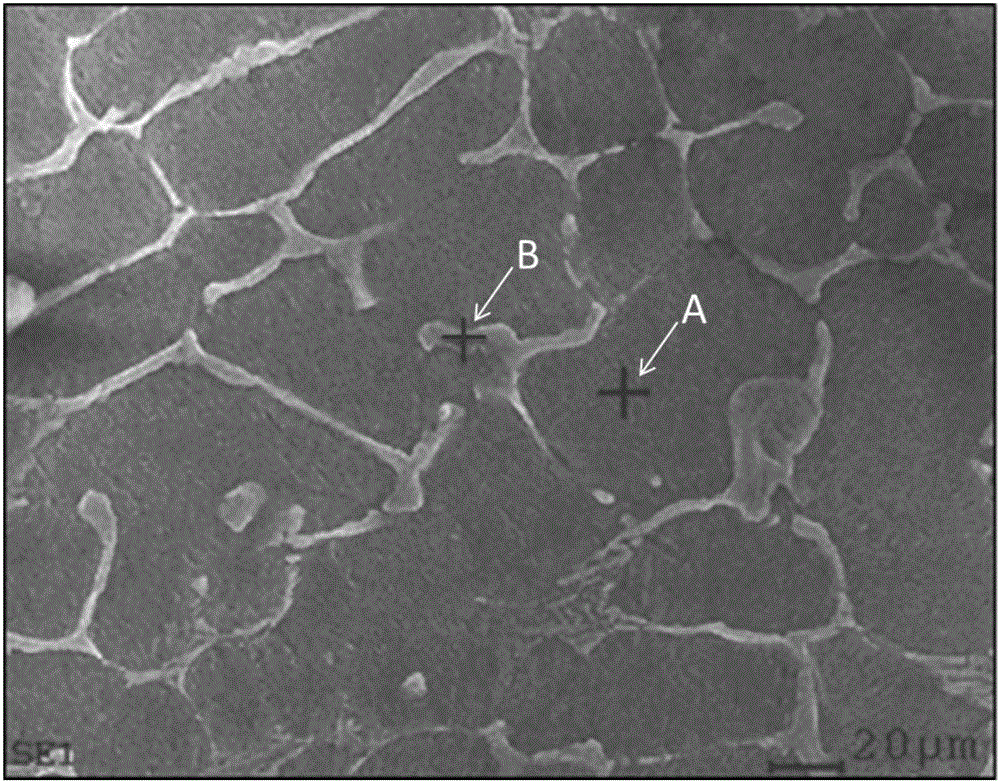

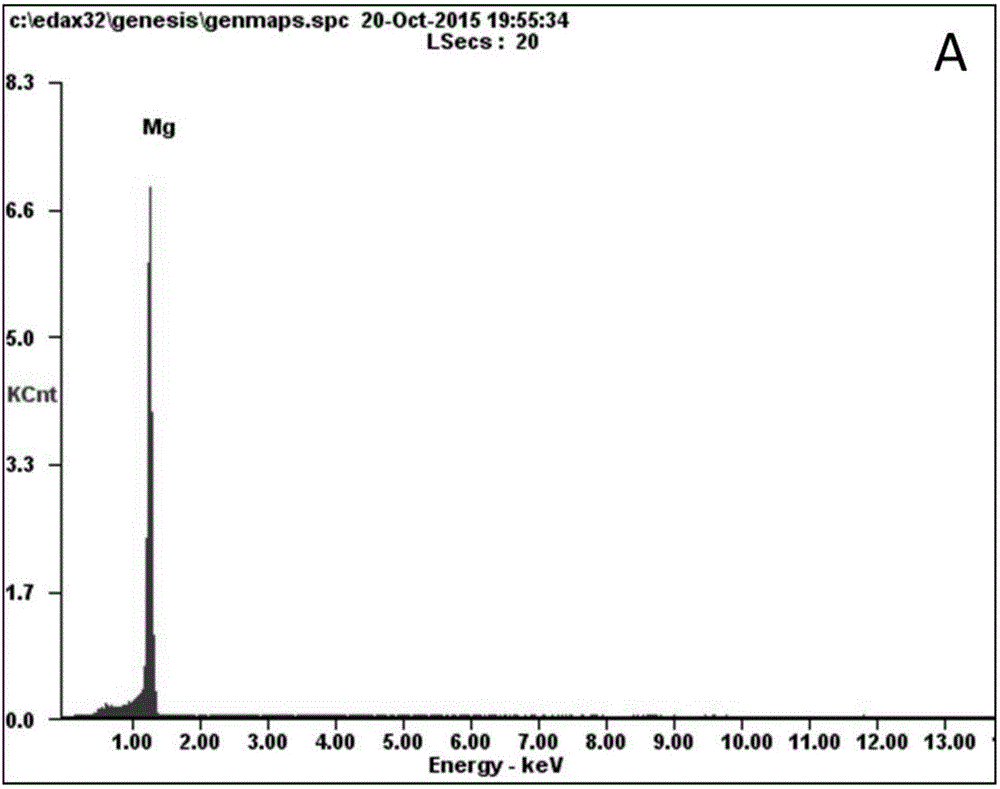

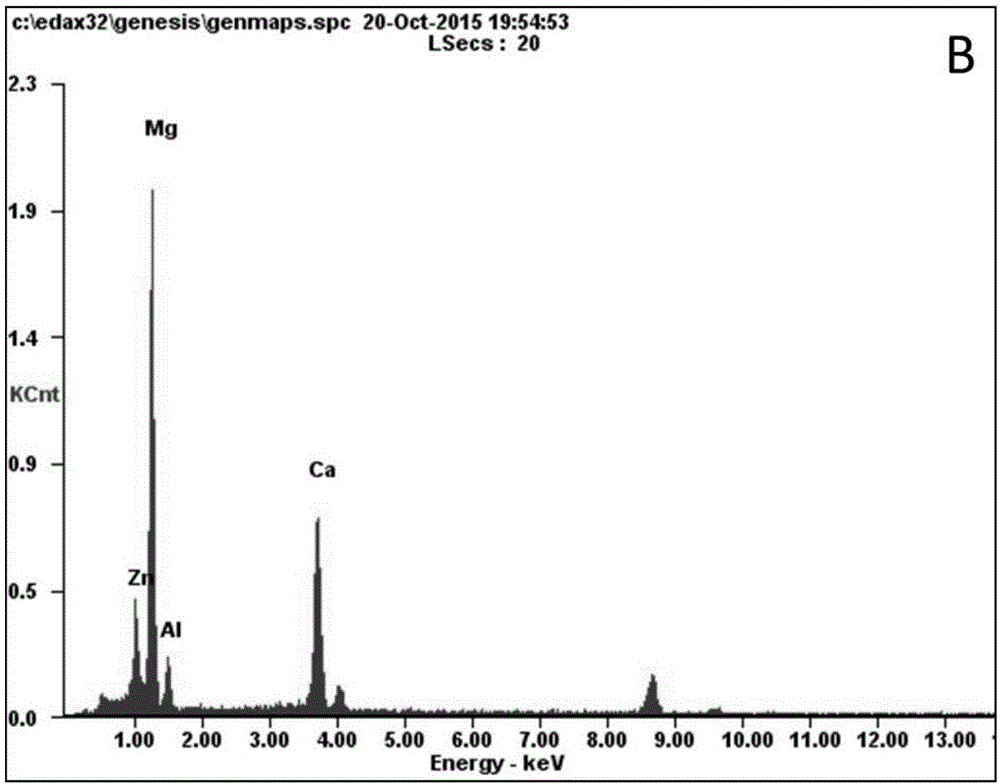

[0048] The tensile properties at room temperature of the extruded Mg-2Ca-2Al-3Zn alloy are shown in Table 1, and the microstructure of the sample is shown in Figure 1. The extruded microstructure is fine and uniform, and the Al 2 Ca and Ca 2 Mg 6 Zn 3 Fully crushed by extrusion, the distribution on the magnesium matrix becomes uniform, thereby improving the tensile properties. After hot extrusion, defects such as keyhole shrinkage and porosity inside the tissue are welded together, and the structure is more dense and continuous. The grains are elongated, thereby increasing the surface area of the grain boundaries and improving deformation resistance. At the same time, some Zn and other elements solid-dissolved in the magnesium matrix can form Coriolis air masses, pin dislocations, and play the role of solid-solution strengthening. The extrusion process parameters of this embodiment are extrusion ratio 16, extrusion temperature 420°C, extrusion speed 0.5-2.5m / min, since t...

Embodiment 2

[0057] Table 2 shows the full immersion test results of Mg-2Ca-2Al-3Zn and AZ31 in 3.5% NaCl solution at 30°C. It can be seen that the corrosion rate of Mg-2Al-2Ca-3Zn is about AZ31 less than AZ31, even better than WE43 with rare earth elements added. The main reason is that a large amount of Al 2 The formation of the Ca phase inhibits the β-Mg 17 Al 12 Phase formation, redistribution of Al elements avoids α-Mg and β-Mg 17 Al 12 The galvanic corrosion between phases increases the self-corrosion potential of the magnesium alloy and reduces the corrosion current density, thereby hindering the corrosion of the magnesium alloy. It can be seen from Figure 4 that the corrosion current density of Mg-2Al-2Ca-3Zn is lower than that of AZ31, indicating that Mg-2Al-2Ca-3Zn has better corrosion resistance. At the same time, in the anode part, the current increases rapidly with the increase of voltage, but the alloy is not passivated, which indicates that the corrosion products have a...

Embodiment 3

[0061] Table 3 compares the ignition point of Mg-2Ca-2Al-3Zn, AZ80, AZ91 and WE43. It is obvious that the ignition point of Mg-2Ca-2Al-3Zn is much higher than that of existing commercial magnesium alloys, even exceeding that of WE43 with rare earth added. This will be very beneficial to the flame retardancy of magnesium alloys in smelting and the use in specific environments, broadening the application of magnesium alloys. The main reason is that the addition of Ca can increase the compactness of the oxide film on the surface of the magnesium alloy. When the molten metal is disturbed, the oxide film containing Ca has better self-repair and regeneration ability. At the same time, the structure contains a large amount of high melting point stable phase Al 2 Ca (melting point 1079°C) hinders the combustion of magnesium and improves the flame retardancy. With the increase of Ca and Al content in Mg-XCa-YAl-ZZn, its flame retardancy will be further improved.

[0062] Table 3 Igni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com