Method for improving superplasticity of zinc-aluminum alloy through heat treatment

A zinc-aluminum alloy and superplasticity technology, which is applied in the field of improving the superplasticity of zinc-aluminum alloy through heat treatment, can solve the problems of low equipment requirements, special equipment, and high cost, and achieve low equipment requirements, increase superplasticity, and increase elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

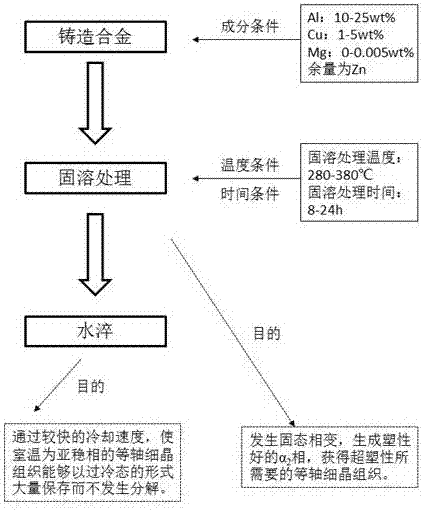

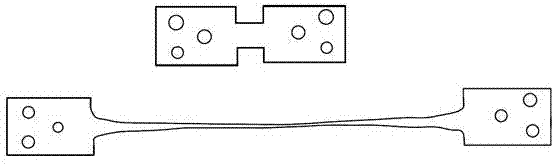

[0019] The cast zinc-aluminum alloy, wherein the mass percentage of each component in the alloy is: 22%Al, 0.2%Cu, 0.005%Mg, and the balance is Zn, according to the national standard GB / T 228.1-2010 Metal material tensile test No. Part: The room temperature test method specifies that the specimen is cut into a thin plate shape for the tensile test specimen. The test specimen includes a gripping end and a deformation zone, the gripping end being symmetrical about the deformation zone. The length of the clamping end is 12 mm, and the width is 9 mm; the length and width of the deformation zone are both 3 mm; the thickness of the test sample is 2 mm.

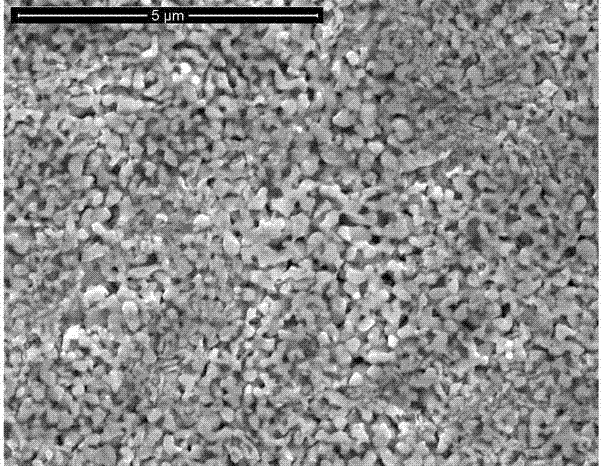

[0020] The test specimens were first solution treated. The solution treatment is to heat the test sample at a constant temperature of 280 ° C for 10 hours to promote the transformation of the internal structure of the alloy into a face-centered cubic structure of zinc-rich α 2 Equivalent axis fine-grained structure. Zinc-rich alp...

Embodiment 2

[0025] Cast zinc-aluminum alloy, wherein the mass percentage of each component in the alloy is: 25%Al, 3%Cu, 0.005%Mg, and the balance is Zn, according to the national standard GB / T 228.1-2010 Metal material tensile test part one : The room temperature test method stipulates that the sample is cut into a tensile test sample in the shape of a thin plate. The test specimen includes a gripping end and a deformation zone, the gripping end being symmetrical about the deformation zone. The length of the clamping end is 12 mm, and the width is 9 mm; the length and width of the deformation zone are both 3 mm; the thickness of the test sample is 2 mm.

[0026] The test specimens were first solution treated. The solution treatment is to heat the test sample at a constant temperature of 360 ° C for 10 hours to promote the transformation of the internal structure of the alloy into a face-centered cubic structure of zinc-rich α 2 Equivalent axis fine-grained structure. Zinc-rich alpha ...

Embodiment 3

[0030] The cast zinc-aluminum alloy, wherein the mass percentage of each component in the alloy is: 15%Al, 1%Cu, 0.005%Mg, and the balance is Zn, according to the national standard GB / T 228.1-2010 Metal material tensile test No. Part: The room temperature test method specifies that the specimen is cut into a thin plate shape for the tensile test specimen. The test specimen includes a gripping end and a deformation zone, the gripping end being symmetrical about the deformation zone. The length of the clamping end is 12 mm, and the width is 9 mm; the length and width of the deformation zone are both 3 mm; the thickness of the test sample is 2 mm.

[0031] The test specimens were first solution treated. The solution treatment is to heat the test sample at a constant temperature of 320 ° C for 10 hours to promote the transformation of the internal structure of the alloy into a face-centered cubic zinc-rich α 2 Equivalent axis fine-grained structure. Zinc-rich alpha 2 The equia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com