Preparation method of superplastic aluminum-based composite material plate

An aluminum-based composite material and superplastic technology, which is applied in the field of aluminum-based composite material processing, can solve the problems of grain recovery and recrystallization growth, difficulty in large-scale production, and inability to be put into industrial applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

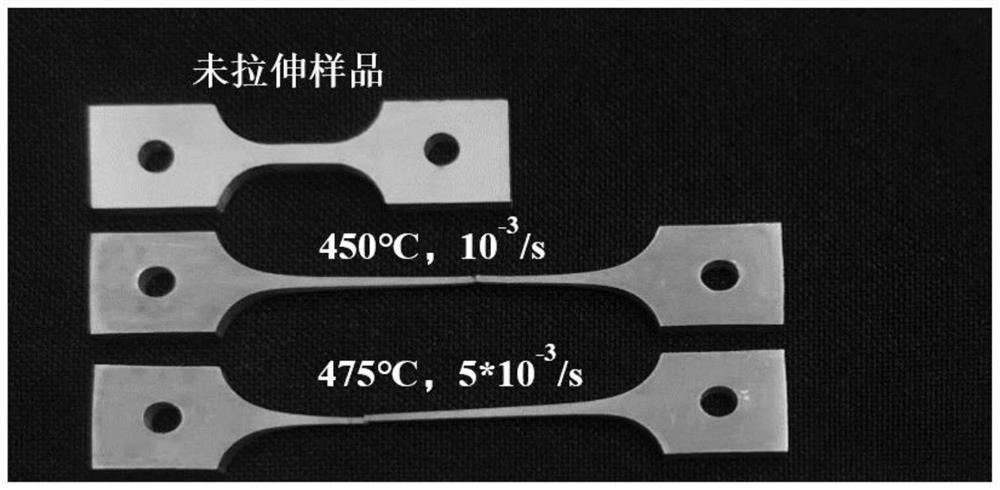

Image

Examples

Embodiment 1

[0028] In situ self-generated 6wt.%TiB obtained by casting 2 / 7050Al composite material plate, its processing method is:

[0029] (1) The particle-reinforced aluminum matrix composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the homogenization heat treatment temperature is 475 °C, and the heat treatment time is 24 hours;

[0030] (2) The in-situ particle reinforced aluminum matrix composite material after homogenization heat treatment is subjected to unidirectional hot extrusion deformation, the hot extrusion temperature is 450 ° C, and the extrusion ratio is 15:1 to obtain the aluminum matrix composite material to be processed;

[0031] (3) The aluminum-based composite material to be processed is subjected to solution treatment at 475°C, kept for 3 hours, and quickly put into 0°C water and quenched to room temperature after the heat preservation is completed;

[0032] (4) The above-mentioned aluminum-bas...

Embodiment 2

[0038] In situ self-generated 6wt.%TiB obtained by casting 2 / 7050Al composite material plate; its treatment method is:

[0039] (1) The particle-reinforced aluminum-based composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the homogenization heat treatment temperature is 475°C, and the homogenization heat treatment time is 24h;

[0040] (2) The in-situ particle reinforced aluminum matrix composite material after homogenization heat treatment is subjected to unidirectional hot extrusion deformation, the hot extrusion temperature is 450 ° C, and the extrusion ratio is 15:1 to obtain the aluminum matrix composite material to be processed;

[0041] (3) The aluminum-based composite material to be processed is subjected to solution treatment at 475°C, kept for 3 hours, and quickly put into 0°C water and quenched to room temperature after the heat preservation is completed;

[0042] (4) The above-mentioned alumi...

Embodiment 3

[0048] In situ self-generated 6wt.%TiB obtained by casting 2 / 7075Al composite material plate, the processing steps are:

[0049] (1) The particle-reinforced aluminum matrix composite material obtained by in-situ autogenous casting is subjected to homogenization heat treatment of alloy elements, the homogenization heat treatment temperature is 475°C, and the homogenization heat treatment time is 24h;

[0050] (2) The in-situ particle-reinforced aluminum matrix composite material after the homogenization heat treatment is subjected to unidirectional hot extrusion deformation, the hot extrusion temperature is 450°C, and the extrusion ratio is 15:1 to obtain the aluminum matrix composite material to be processed;

[0051] (3) The aluminum-based composite material to be processed is subjected to solution treatment at 475°C, kept for 3 hours, and quickly put into 0°C water and quenched to room temperature after the heat preservation is completed;

[0052] (4) The above-mentioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com