Method for improving superplasticity of semi-stable beta titanium alloy

A technology of β titanium alloy and superplasticity, which is applied in the field of titanium alloy, can solve the problems of limiting the wide application of metastable β titanium alloy and low superplasticity of metastable β titanium alloy, and achieve the effect of increasing elongation and increasing superplasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

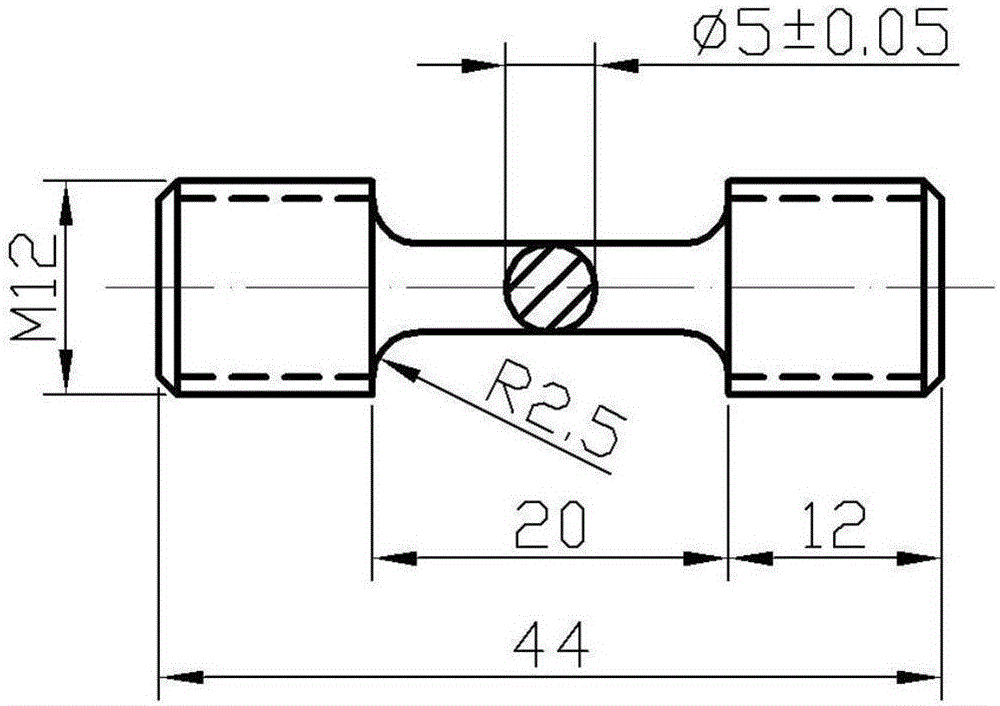

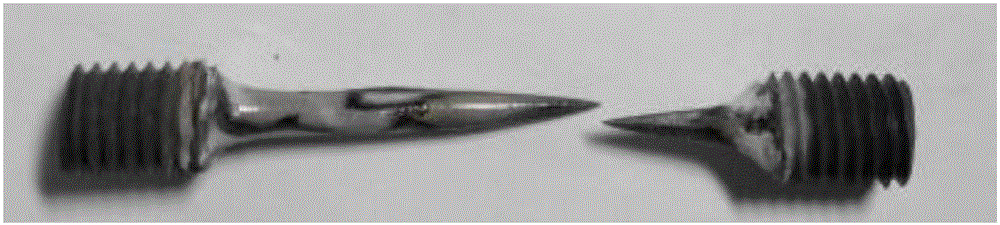

[0047] The metastable β titanium alloy Ti-15Mo-3Al-2.7Nb-0.2Si was placed in an XY-1200 high-temperature box-type resistance furnace for pre-aging treatment. The temperature in the resistance furnace was limited to 520°C. The metastable β titanium alloy was After 20 minutes of heat preservation in the resistance furnace, take it out and cool it naturally in the air, and the cooled metastable β titanium alloy according to figure 1 The samples shown were processed and then tested on a SANS-CMT4104 electronic tensile testing machine at 840°C and 0.001s -1 Under the condition of the strain rate, the tensile performance test is carried out, and the sample after fracture is as follows Figure 4 As shown, the obtained elongation was 287%.

Embodiment 2

[0049] On the basis of the pre-aging treatment parameters in Example 1, keep the pre-aging temperature 520°C unchanged, change the pre-aging time, the pre-aging time is 40min and 70min respectively, and the metastable β titanium alloy Ti-15Mo-3Al-2.7Nb- 0.2 Si is placed in XY-1200 high temperature box-type resistance furnace for pre-aging treatment, and then it is taken out and cooled naturally in the air, and the cooled metastable β titanium alloy is figure 1 The samples shown were processed and then tested on a SANS-CMT4104 electronic tensile testing machine at 840°C and 0.001s -1 Under the condition of the strain rate, the tensile property test is carried out. After the pre-aging temperature is 520 ℃, and the pre-aging holding time is 40min, the fractured sample is as follows: Figure 5 As shown, the obtained elongation rate is 361.8%, and the pre-aging treatment is 520 ° C for 70 min after fracture. Figure 6 As shown, the obtained elongation was 303%. Comparing the elon...

Embodiment 3

[0051] On the basis of the pre-aging treatment parameters in Example 3, keep the pre-aging heat preservation time 40min unchanged, change the pre-aging temperature, the pre-aging temperature is 440°C, 480°C and 545°C respectively, and the metastable β titanium alloy Ti-15Mo- 3Al-2.7Nb-0.2Si was placed in an XY-1200 high-temperature box-type resistance furnace for pre-aging treatment, and then it was taken out and cooled naturally in the air, and the cooled metastable β-titanium alloy was figure 1 The samples shown were processed and then tested on a SANS-CMT4104 electronic tensile testing machine at 840°C and 0.001s -1 Under the condition of the strain rate, the tensile performance test is carried out. The pre-aging treatment after the pre-aging temperature is 440 ° C and the pre-aging holding time is 40 minutes is shown in 7. The obtained elongation is 174%, and the pre-aging treatment is 480 ℃ holding for 40min after breaking the sample such as Figure 8 As shown, the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com