Nanophase ceramic heat-insulation window membrane

A nano-ceramic, thermal insulation technology, applied in protective equipment, clothing, protective clothing, etc., can solve the problems of easy-fading thermal insulation effect, weather resistance, large apparent haze of products, low visible light transmission, etc., and achieve good clarity , improved flexibility, obvious heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but is not limited thereto.

[0015] The raw materials used in the examples, unless otherwise specified, are commercially available industrial products, which can be purchased through commercial channels.

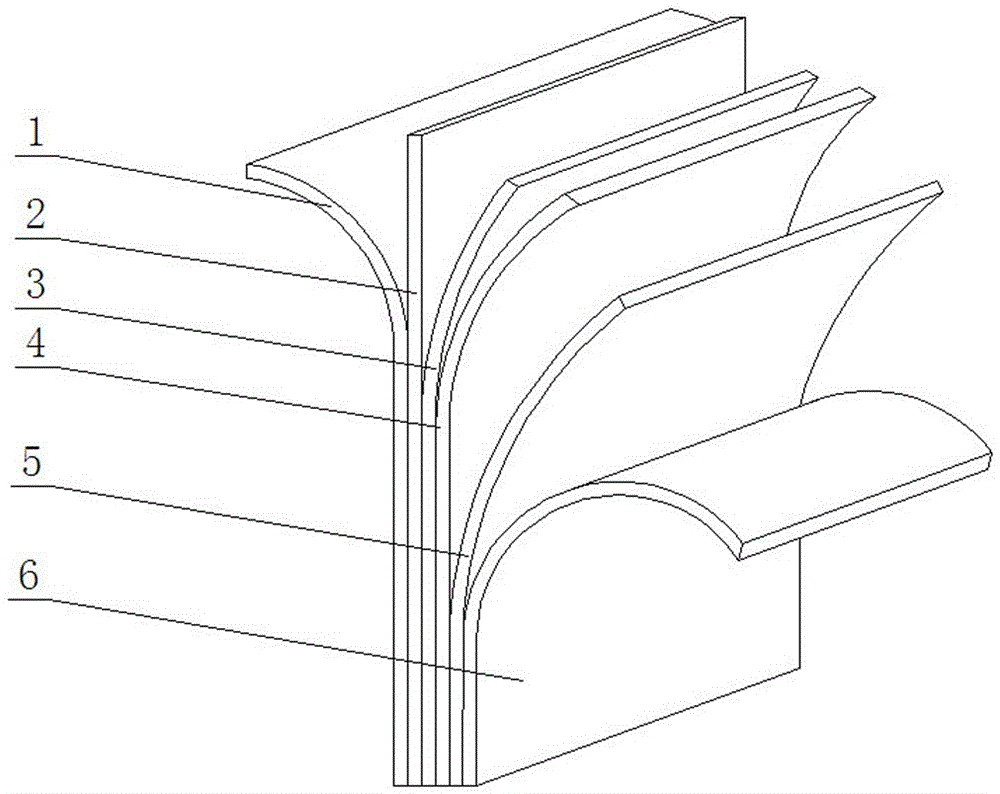

[0016] Such as figure 1 As shown, a nano-ceramic heat-insulating window film is composed of a wear-resistant layer 1, a base film layer 2, a nano-ceramic heat-insulating adhesive layer 3, a functional film layer 4, a pressure-sensitive adhesive layer 5 and a protective film layer 6. , and each layer is combined into one;

[0017] The wear-resistant layer 1 is bonded to one surface of the base film layer 2 by ultraviolet light curing, the nano-ceramic thermal insulation adhesive layer 3 is thermally cured and bonded to the other surface of the base film layer 2, and one surface of the functional film layer 4 is compounded on the nano On the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com