Extra-deep drawing interstitial free steel and production method thereof

A technology of interstitial-free steel and ultra-deep drawing, which is applied in the field of smelting hot-rolled pickled strip steel for automobiles, can solve the problems of increased strength and reduced formability, and achieves the effect of good resistance to secondary processing brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

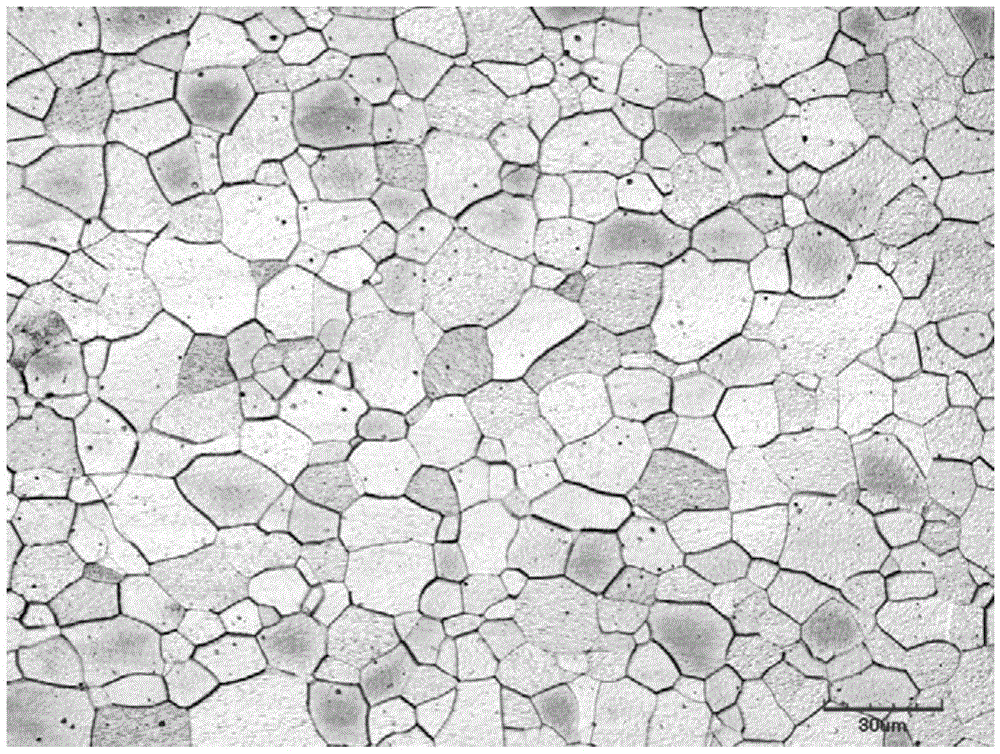

Image

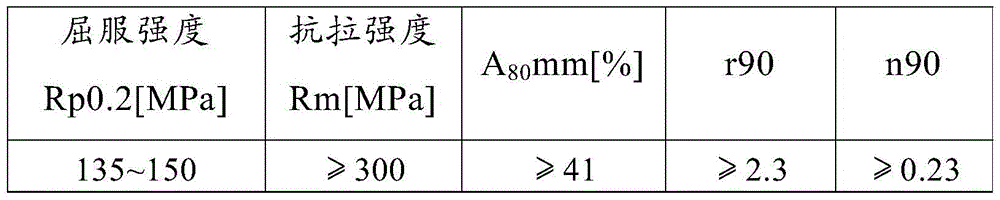

Examples

Embodiment 1

[0054] An ultra-deep drawing interstitial-free steel provided in an embodiment of the present invention has a chemical composition and a mass percent content of: C: 0.0020%, Si: 0.0021%, Mn: 0.20%, P: 0.015%, S: 0.006%, Ti: 0.06%, B: 0.0004%, N: ≤ 0.0022%, and the balance is iron and unavoidable impurities.

[0055] The method for producing above-mentioned ultra-deep drawing interstitial-free steel, its steps are as follows:

[0056] 1) The steelmaking process of molten iron three-stripping, LF refining, and RH refining is adopted, and the product is smelted and continuously cast into billets according to the predetermined composition. The chemical composition and mass percentage content are: C: 0.0020%, Si: 0.0021%, Mn: 0.20%, P: 0.015%, S: 0.006%, Ti: 0.058%, B: 0.0004%, N: ≤ 0.0022%, and the balance is iron and unavoidable impurities.

[0057] 2) After heating the slab, rough rolling and finishing rolling are carried out to obtain a hot-rolled plate. The heating temperatur...

Embodiment 2

[0061] An ultra-deep drawing interstitial-free steel provided in an embodiment of the present invention has a chemical composition and a mass percentage content of: C: 0.0025%, Si: 0.0008%, Mn: 0.12%, P: 0.017%, S: 0.001%, Ti: 0.055%, B: 0.0003%, N: 0.0012%, and the balance is iron and unavoidable impurities.

[0062] A method for producing an ultra-deep drawn interstitial-free steel with a tensile strength above 300 MPa, the steps of which are:

[0063] 1) The steelmaking process of molten iron three-stripping, LF refining, and RH refining is adopted, and the product is smelted and continuously cast into billets according to the predetermined composition. The chemical composition and mass percentage content are: C: 0.0025%, Si: 0.0008%, Mn: 0.12%, P: 0.017%, S: 0.001%, Ti: 0.05%, B: 0.0003%, N: 0.0012%, and the balance is iron and unavoidable impurities.

[0064] 2) After heating the slab, rough rolling and finish rolling are carried out to obtain a hot-rolled slab, and the ...

Embodiment 3

[0068] An ultra-deep drawing interstitial-free steel provided in an embodiment of the present invention has a chemical composition and a mass percent content of: C: 0.0018%, Si: 0.0017%, Mn: 0.16%, P: 0.016%, S: 0.006%, Ti: 0.05%, B: 0.0004%, N: 0.0028%, and the balance is iron and unavoidable impurities.

[0069] The method for producing above-mentioned ultra-deep drawing interstitial-free steel, its steps are as follows:

[0070] 1) The steelmaking process of molten iron three-stripping, LF refining, and RH refining is adopted, and the product is smelted and continuously cast into billets according to the predetermined composition. The mass percentage content is: C: 0.0018%, Si: 0.0017%, Mn: 0.16%, P: 0.016%, S: 0.006%, Ti: 0.07%, B: 0.0004%, N: 0.0028%, and the balance is iron and unavoidable impurities.

[0071] 2) After heating the slab, rough rolling and finish rolling are carried out to obtain a hot-rolled plate. The heating temperature is 1220°C, the rough rolling exi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com