6082 aluminium alloy thick-wall pipe production technology

A production process and technology of aluminum alloy, which is applied in the field of aluminum alloy profile manufacturing, can solve the problem that the mechanical properties of 6082 aluminum alloy thick-walled pipe can not meet the production requirements, and the elongation after fracture can not meet the production requirements. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

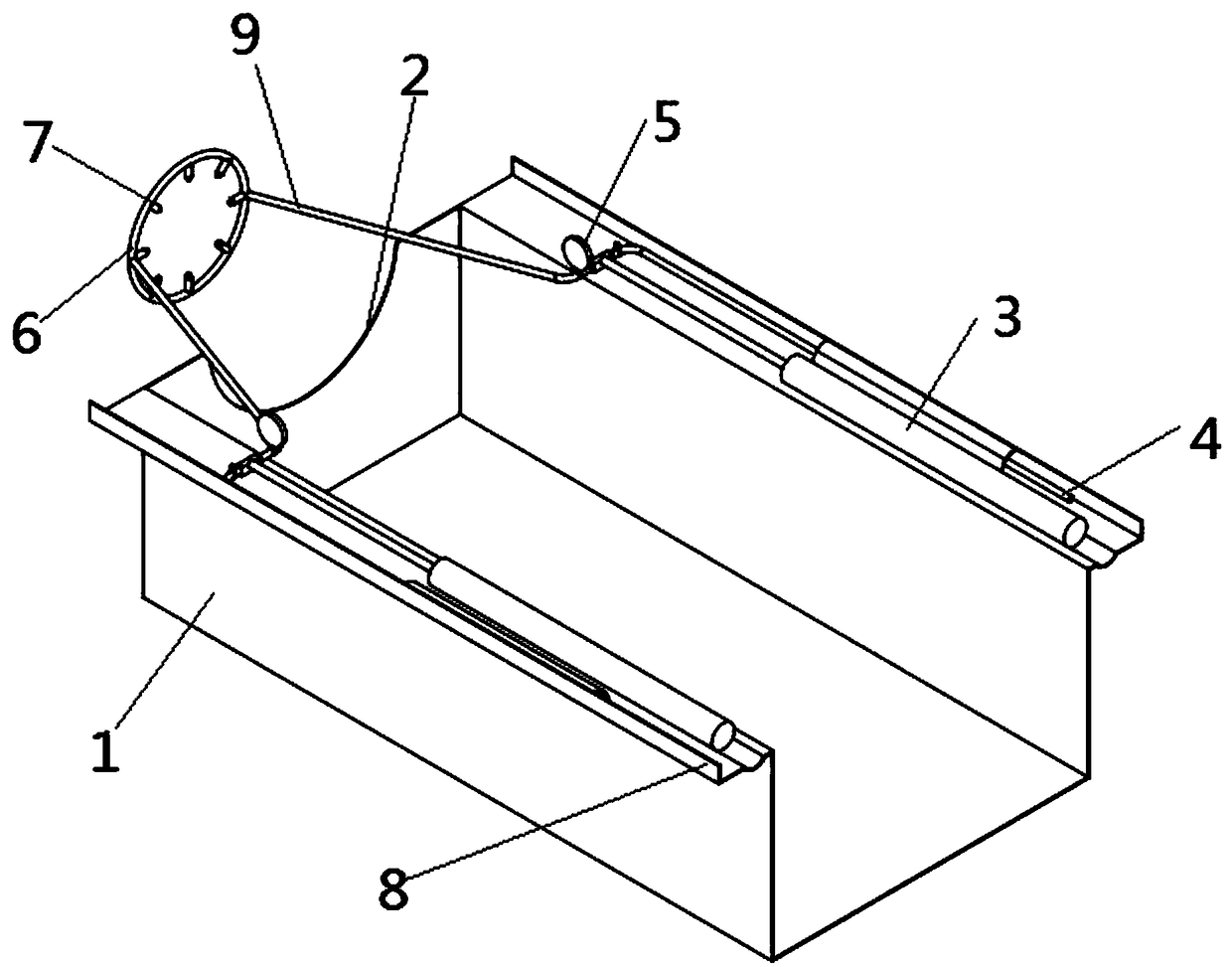

Image

Examples

Embodiment 1

[0034] A kind of 6082 aluminum alloy thick-walled pipe production process, comprises the steps:

[0035] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio. The ratio of the mass percentage of each element of the aluminum alloy raw material is as follows:

[0036] element

Si

Mg

Cu

mn

Cr

Ti

Fe

Zn

Impurities

Al

content

1.19

0.94

0.20

0.84

0.13

0.11

0.19

0.05

0.10

margin

[0037] Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt into liquid aluminum alloy. The melting temperature is 700°C. After the smelted liquid aluminum alloy is left still, refined, slag removed, on-line degassing, and filtered , melting and casting the liquid aluminum alloy into an aluminum alloy ingot;

[0038] B. Homogenization: Homogenize the aluminum alloy ingots in a homogenizat...

Embodiment 2

[0045] The difference between embodiment 2 and embodiment 1 is that, in step A, the mass percentage ratio of each element of the aluminum alloy raw material is as follows:

[0046] element

[0047] The melting temperature is 750°C.

Embodiment 3

[0049] The difference between Example 3 and Example 1 is that in step B, the aluminum alloy ingot is subjected to homogenization treatment in a homogenizing furnace, the temperature of the homogenization treatment is 560° C., and the holding time is 10 h. Strong wind to cool to room temperature.

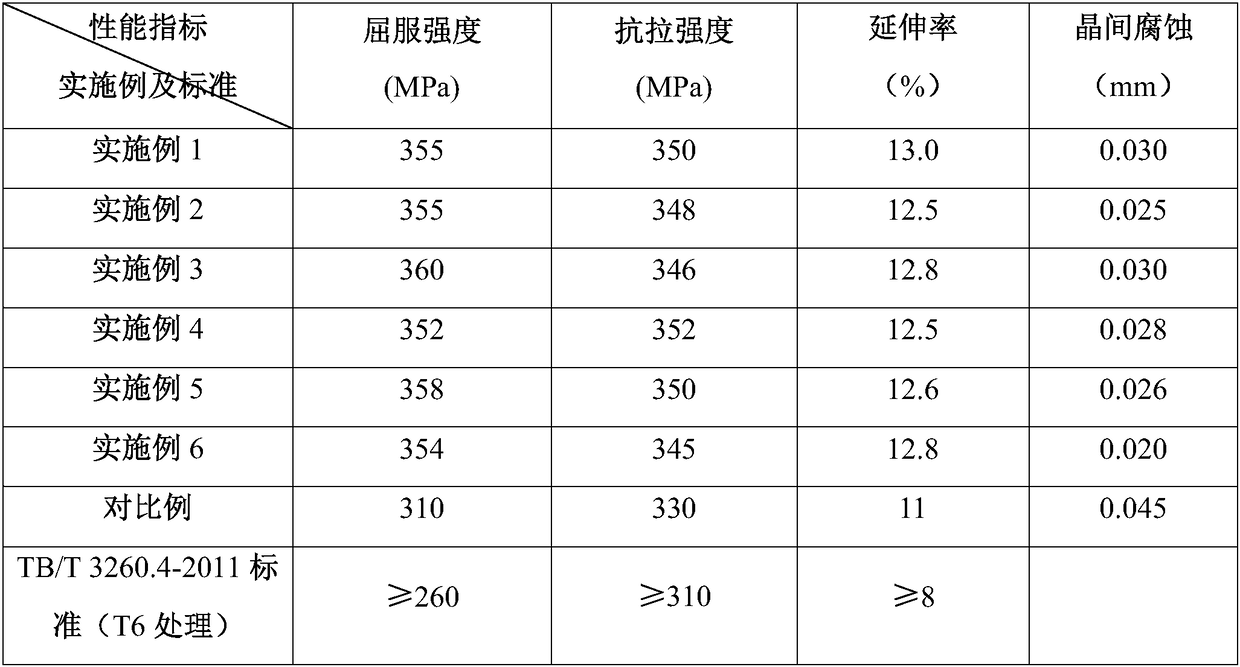

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com