Automotive cold-rolled high-strength steel and production method thereof

A high-strength steel and production method technology, applied in the field of metallurgical materials, can solve the problems of high carbon content and poor welding performance, and achieve the effects of high elongation after fracture, good stamping performance, and high elongation after fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

[0023] A cold-rolled high-strength steel for automobiles, the model is SPFC390, its chemical composition and mass percentage are: C≤0.006; Si: 0.10-0.20; Mn: 0.50-0.80; P: 0.06-0.10; S≤0.005; Al≤ 0.040; Ti: 0.040~0.060; N≤50ppm; the rest is Fe and unavoidable inclusions.

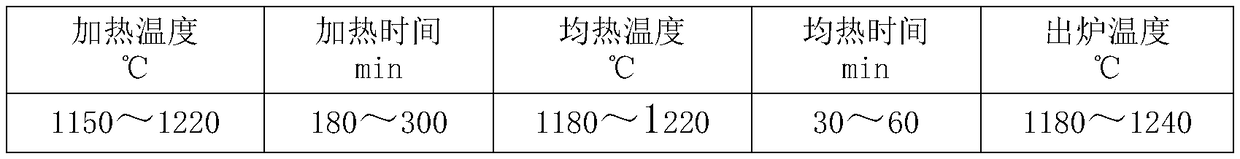

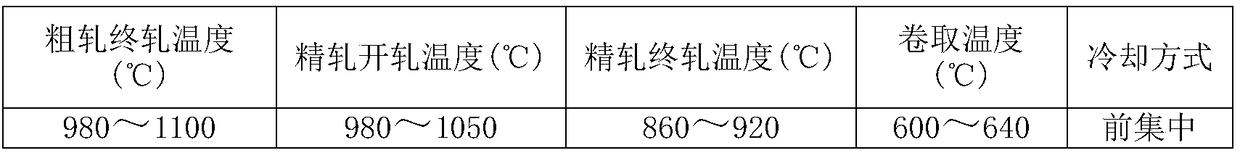

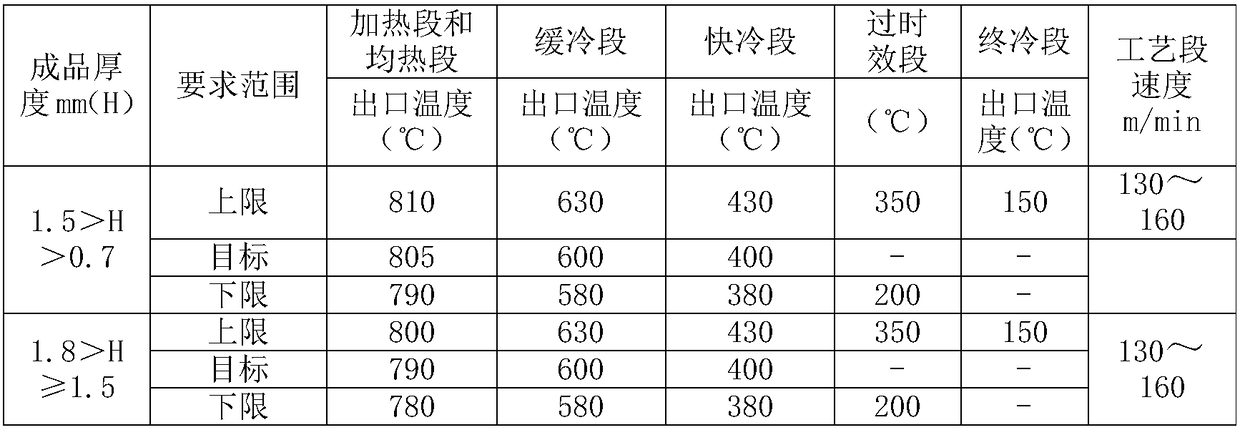

[0024] A production method of cold-rolled high-strength steel for automobiles comprises: blast furnace molten iron→converter smelting→RH refining→slab continuous casting→hot rolling→cold rolling.

[0025] Converter smelting adopts KR pre-desulfurized molten iron, deoxidation alloying of ferrosilicon, ferromanganese, ferroniobium and ferro-titanium alloys, and argon blowing and stirring in the whole process of molten steel.

[0026] After RH cycle for more than 3 minutes, add metal manganese, phosphorus iron, titanium iron and other alloys to adjust the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com