Preparation method of high-strength 550L automobile beam steel

A technology of automobile frame steel and high strength, which is applied in the manufacture of converters, etc., and can solve the problems of heavy weight, low strength, and difficult cold forming of automobiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

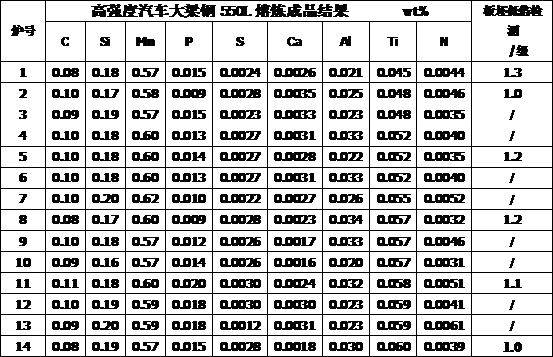

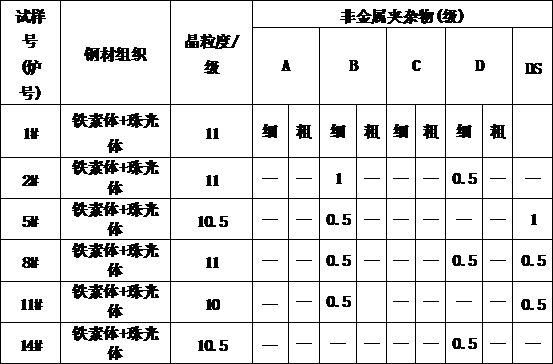

[0029] A high-intensity 550L automotive beam steel preparation method, including the following steps: 1. Ingredient design: The components of the bullying steel become C: 0.080 ~ 0.11%, Si: ≤0.20%, Mn: 0.55 ~ 0.65 wt%, P: ≤0.018 wt%, S: ≤0.004 wt%, Ti: 0.045 ~ 0.060 wt%, Al: 0.020 ~ 0.0045 wt%, N: 0.0030 ~ 0.0045 wt%, steel TO ≤ 0.0020 wt%, margin is impurities; 2. Preparation method: Using iron water desulfurization pretreatment, 120T top-bottomed reincarnation casting, LF refining treatment, slab continuous casting, 1750 hot rolling process production, [1] converter smelting, steel control: [C]: 0.06 -0.08%, [P]: ≤0.015%, [S]: ≤0.008%, [O] ≤400ppm. The converter export steel is made of octal stone deoxidation, in order to prevent the stalline and steel water, the steel is tumbling and exploding, and the fluorite, calcium stones, and active lime are mixed in 1: 1: 3, and the particle size of the three raw materials is 10. -15mm, in the process of time separation of 1 minute, 2 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com