Precipitation strengthening type high-strength and high-toughness medium-manganese steel plate and preparation method thereof

A technology of precipitation strengthening and manganese steel plate, which is applied in the field of precipitation strengthening high-strength and toughness medium manganese steel plate and its preparation, can solve the problem that the plastic-toughening effect of Cu-rich phase strengthening retained austenite cannot be optimally utilized, and achieve microstructure and Good uniformity of mechanical properties, improved elongation after fracture, and high hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

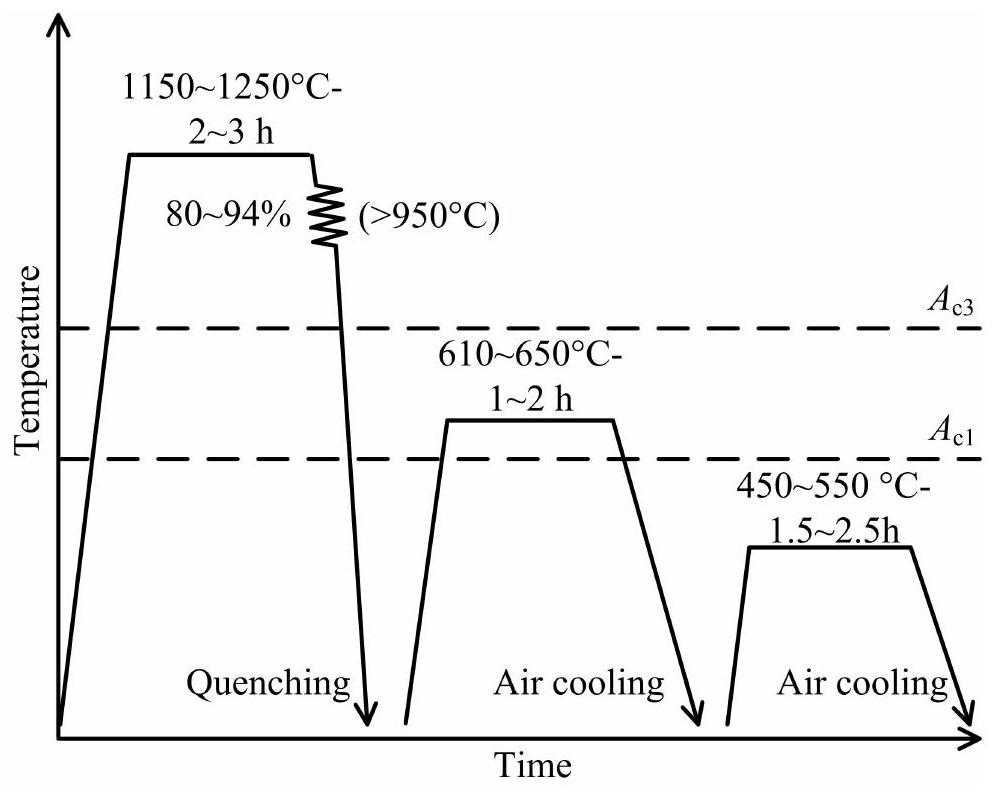

[0058] The present invention also provides a preparation method of the precipitation-strengthened high-strength and tough medium manganese steel plate, the preparation method comprising:

[0059] Using the chemical composition of the precipitation-strengthening high-strength and toughness medium manganese steel plate to melt and forge to obtain a billet;

[0060] rolling the billet to obtain a hot-rolled plate;

[0061] The hot-rolled sheet is annealed and tempered sequentially to obtain a precipitation-strengthened high-strength and tough medium-manganese steel sheet; wherein, the temperature of the annealing is 610°C-650°C, and the soaking time of the annealing is 1h-2h; The tempering temperature is 450°C-550°C, and the soaking time of the tempering is 1.5h-2.5h.

[0062] The preparation method of the precipitation-strengthened high-strength and toughness medium manganese steel plate provided by the present invention is based on the following principles:

[0063] Two-phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com