Aluminum alloy lock core

An aluminum alloy, lock cylinder technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems that cannot be directly extruded, cannot meet turning, etc., and achieves the effect of cost saving and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

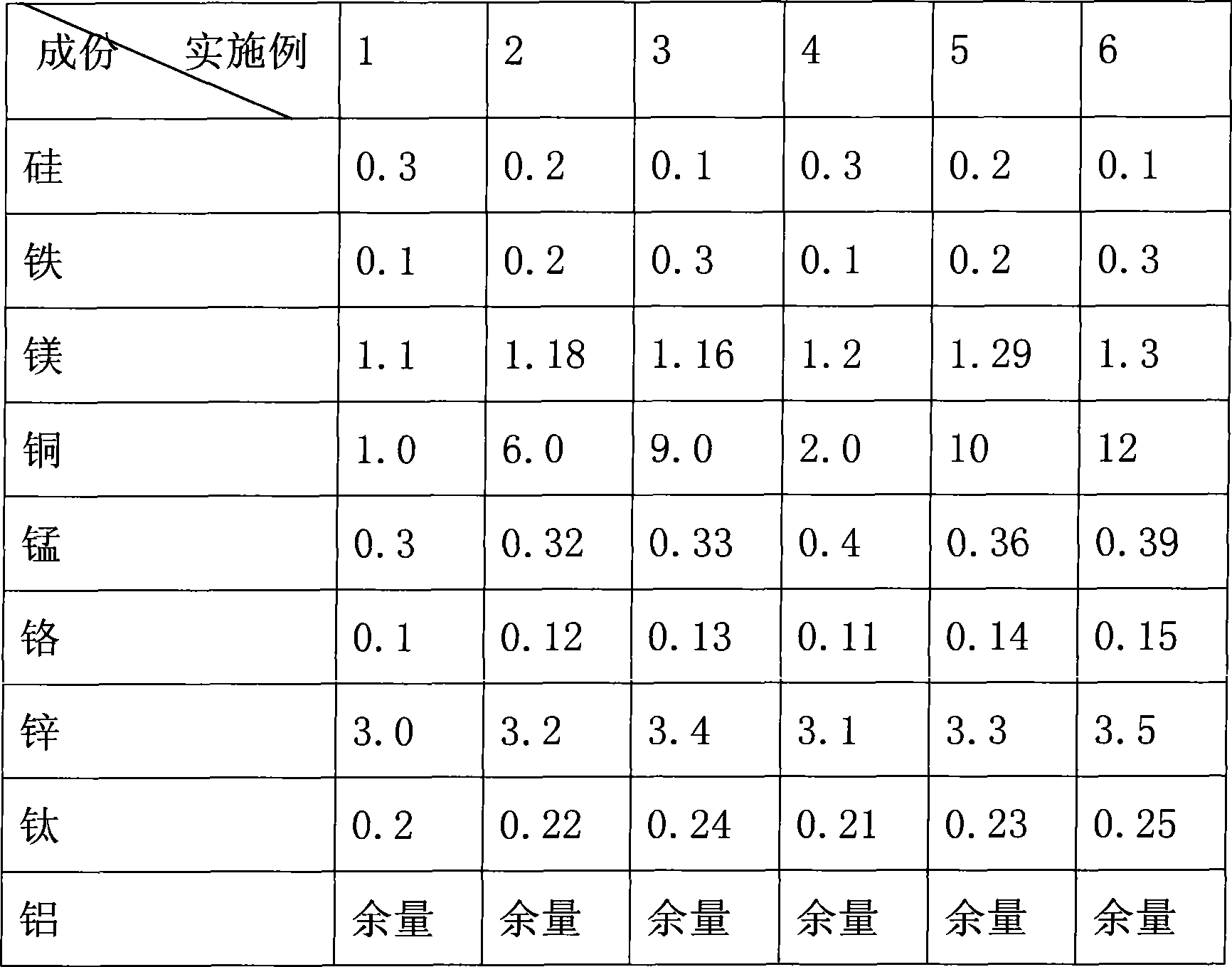

[0007] The technical solutions of the present invention will be further specifically described below through specific examples. Provide 6 embodiments below in tabular form, and the composition of lock cylinder and parts by weight thereof are shown in the following table in each embodiment:

[0008] Proportion content of ingredients used in aluminum alloy lock cylinder (by weight parts)

[0009]

[0010] The preparation method of the lock cylinder in each embodiment is the same: heat the aluminum alloy bar made of the material used to about 380°C, and then go through the processes of die extrusion, preliminary cutting, straightening, etc., and then saw and cut to length, and frame it. Get the required aluminum alloy lock cylinder. The obtained aluminum alloy lock cylinder has better strength, hardness and better ductility, and can meet the needs of further processing and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com