Binder composition for producing template, and method for producing template

A technology of composition and binder, which is applied in the direction of casting moulds, manufacturing tools, casting molding equipment, etc., can solve problems such as internal cracks, unqualified castings, and operator hazards, and achieve the effect of improving the final strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

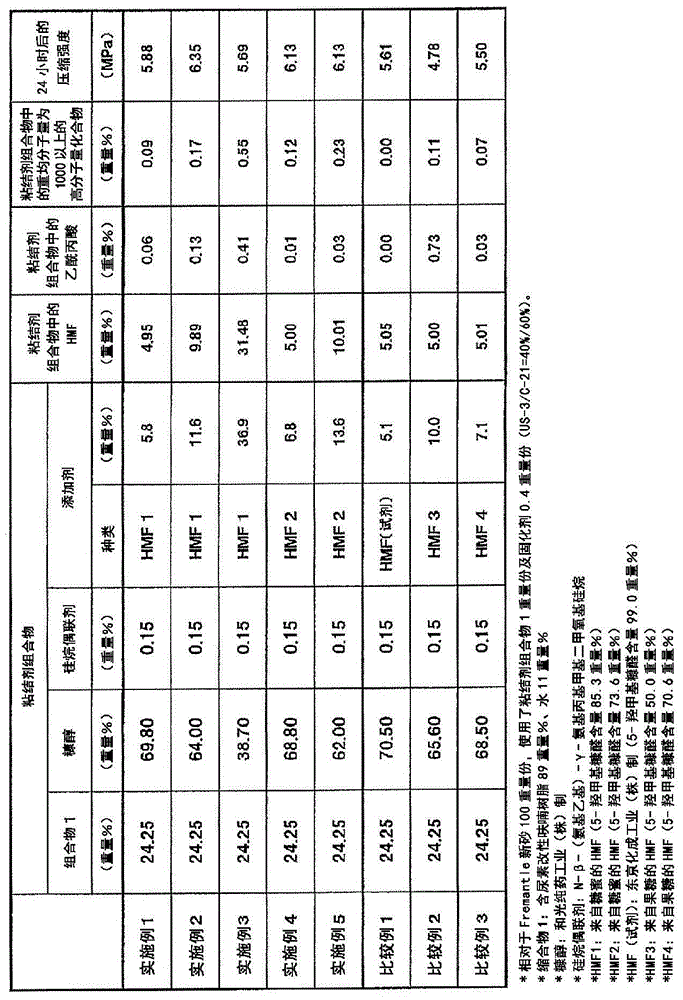

Examples

Embodiment

[0111] Hereinafter, the present invention will be described using specific examples and the like. In addition, the evaluation item in an Example etc. was measured as follows.

[0112]

[0113] The content was calculated by the following method using ion chromatography.

[0114] Device: DX-320 (manufactured by Dionex Corporation, Japan)

[0115] Column: Ion Pac AS11HC

[0116] Eluent: 10mM KOH (0min) → 40mM KOH (25min)

[0117] Flow: 1.5mL / min

[0118] Autosuppressor (Autosuppressor): ASRS-300 (manufactured by Dionex Corporation of Japan)

[0119] Detection: Conductivity

[0120] MS device: LCMS-2010EV (manufactured by Shimadzu Corporation)

[0121] Flow rate: 1mL / min

[0122]

[0123] The content was calculated by the following method using gel permeation chromatography.

[0124] Detector: RI

[0125] Column: TSKgelα-M×2 (manufactured by Tosoh Corporation)

[0126] Temperature: 40°C

[0127] Eluent: N,N-Dimethylformamide

[0128] Flow: 1.0mL / min

[0129] Conve...

manufacture example 1

[0193]

[0194] Add 20.0 g of spent molasses (manufactured by Kaset Thai Sugar Co.), 40.0 g of ion-exchanged water, and 160 g of methyl isobutyl ketone (manufactured by Wako Pure) to a 500 mL titanium electromagnetic valve type autoclave (manufactured by Nitto High Pressure Co., Ltd.). Pharmaceutical Co., Ltd.) and 2.0 g of phosphoric acid (85% purity, manufactured by Aldrich). After sealing the container, the inner space was fully replaced with nitrogen gas. Thereafter, the temperature was raised to 140° C. while fully stirring the contents, and after reaching 140° C., the reaction was carried out while maintaining heat retention and stirring for 3 hours. In addition, the gauge pressure at the time of reaction was 0.4 MPa. After completion of the reaction, the temperature of the content was cooled to 30° C. or lower while maintaining stirring. After cooling, the contents were filtered to remove solid components, samples were collected from the aqueous solution phase and t...

manufacture example 2

[0196]

[0197] Add 20.0 g of spent molasses (manufactured by Kaset Thai Sugar Co.), 40.0 g of ion-exchanged water, and 160 g of methyl isobutyl ketone (manufactured by Wako Pure) to a 500 mL titanium electromagnetic valve type autoclave (manufactured by Nitto High Pressure Co., Ltd.). Pharmaceutical Co., Ltd.) and 2.0 g of phosphoric acid (85% purity, manufactured by Aldrich). After sealing the container, the inner space was fully replaced with nitrogen gas. Thereafter, the temperature was raised to 140° C. while fully stirring the contents, and after reaching 140° C., the reaction was carried out while maintaining heat retention and stirring for 3 hours. In addition, the gauge pressure at the time of reaction was 0.4 MPa. After completion of the reaction, the temperature of the content was cooled to 30° C. or lower while maintaining stirring. After cooling, the contents were filtered to remove solid content, and then a 50% by weight aqueous sodium hydroxide solution was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com