Composite connector for FRP bars and assembly method thereof

An assembly method and composite technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as inapplicability, and achieve the effects of convenient implementation, reasonable design and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

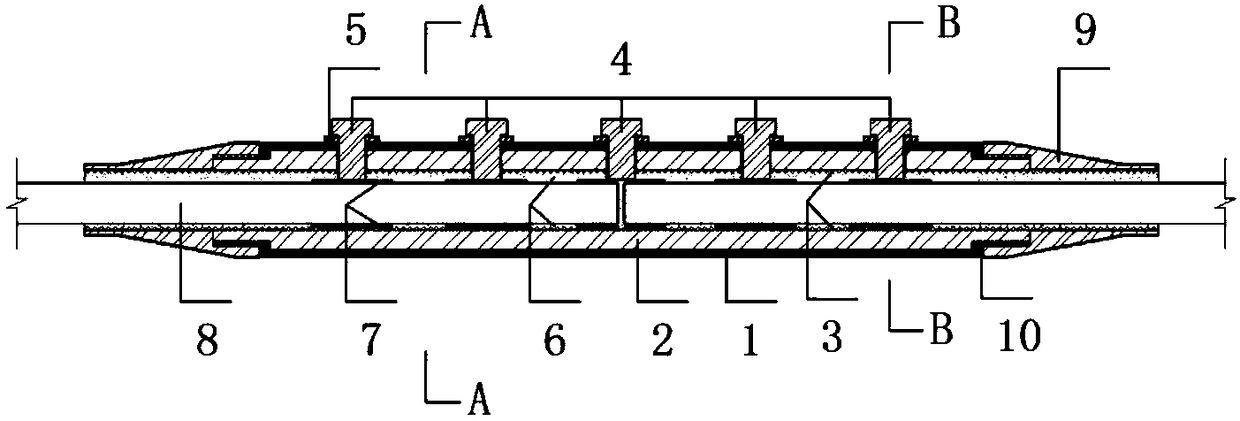

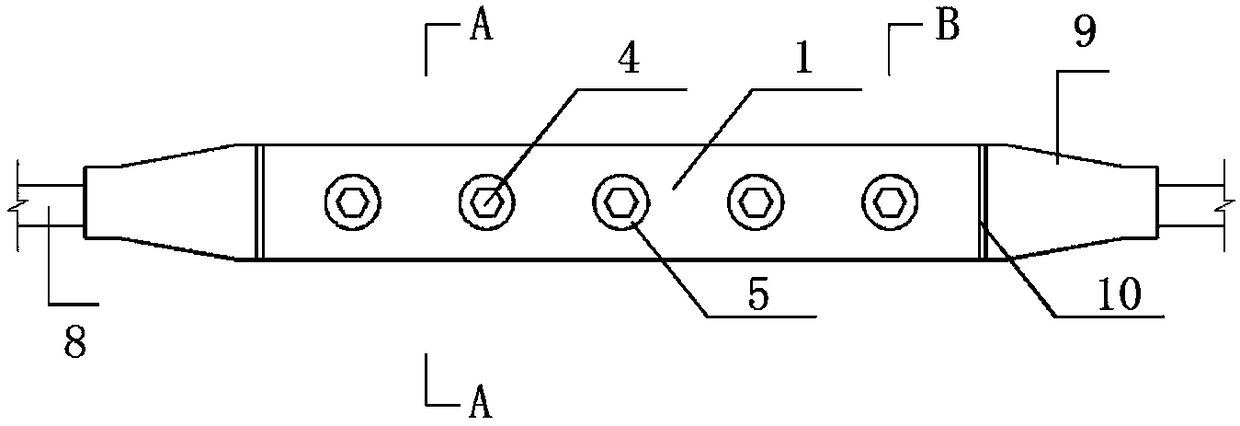

[0048] A method for assembling the above-mentioned composite connector for FRP bars, comprising the following steps:

[0049] Step 1. Extend the contact part of the FRP rib and the hexagon head bolt to a certain length and paste the arc-shaped soft metal gasket;

[0050] Step 2. After the arc-shaped soft metal gasket is glued tightly, insert two sections of FRP bars from the two ports of the steel sleeve respectively, and turn the FRP bars to adjust the position of the arc-shaped soft metal gasket; make the ends of the two sections of FRP bars The part is located in the middle of the steel sleeve, so that the insertion lengths of the two FRP bars are the same; and a hexagon head bolt with a bolt washer is screwed on each bolt hole at both ends to fix the bar to prevent it from sliding;

[0051] Step 3: Set the plug washer on the stainless steel plug, pass the two stainless steel plugs through the two sections of FRP ribs respectively, screw the stainless steel plug to make it ...

Embodiment 2

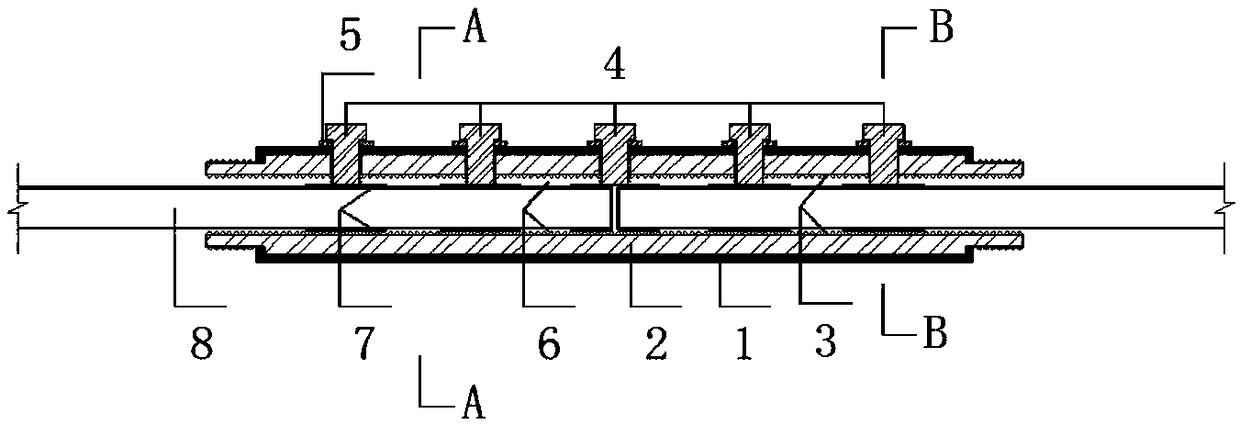

[0056] A method for assembling the above-mentioned composite connector for FRP bars, comprising the following steps:

[0057] Step 1. Extend the contact part of the FRP rib and the hexagon head bolt to a certain length and paste the arc-shaped soft metal gasket;

[0058] Step 2. After the arc-shaped soft metal gasket is glued tightly, coat the inner walls of multiple pre-tightening sleeves with epoxy resin glue and evenly set them on the FRP bars; install two sections of FRP bars from the two ports of the steel sleeve respectively. Insert and turn the FRP bars to adjust the position of the arc-shaped soft metal gasket; make the ends of the two sections of FRP bars be located in the middle of the steel sleeve, so that the insertion lengths of the two sections of FRP bars are the same; and screw at the bolt holes at each end A hexagon head bolt covered with a bolt washer is used to fix the reinforcement to prevent it from sliding; the multiple pre-tightening sleeves are elastic ...

Embodiment 3

[0064] A method for assembling the above-mentioned composite connector for FRP bars, comprising the following steps:

[0065] Step 1. Extend the contact part of the FRP rib and the hexagon head bolt to a certain length and paste the arc-shaped soft metal gasket;

[0066] Step 2. After the arc-shaped soft metal gasket is glued tightly, insert two sections of FRP bars from the two ports of the steel sleeve respectively, and turn the FRP bars to adjust the position of the arc-shaped soft metal gasket; make the ends of the two sections of FRP bars The part is located in the middle of the steel sleeve, so that the insertion lengths of the two FRP bars are the same; and a hexagon head bolt with a bolt washer is screwed on each bolt hole at both ends to fix the bar to prevent it from sliding;

[0067] Step 3: Set the plug washer on the stainless steel plug, pass the two stainless steel plugs through the two sections of FRP ribs respectively, screw the stainless steel plug to make it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com