Production method of foamed concrete block manufactured from steel slag

A technology of foam concrete and production methods, applied in applications, household utensils, ceramic products, etc., can solve problems affecting the sustainable development of the steel industry, cracking of building material products, and difficulty in utilization, etc., to achieve comprehensive utilization of resources and energy saving. The effect of reducing rowing and drying shrinkage and improving final strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

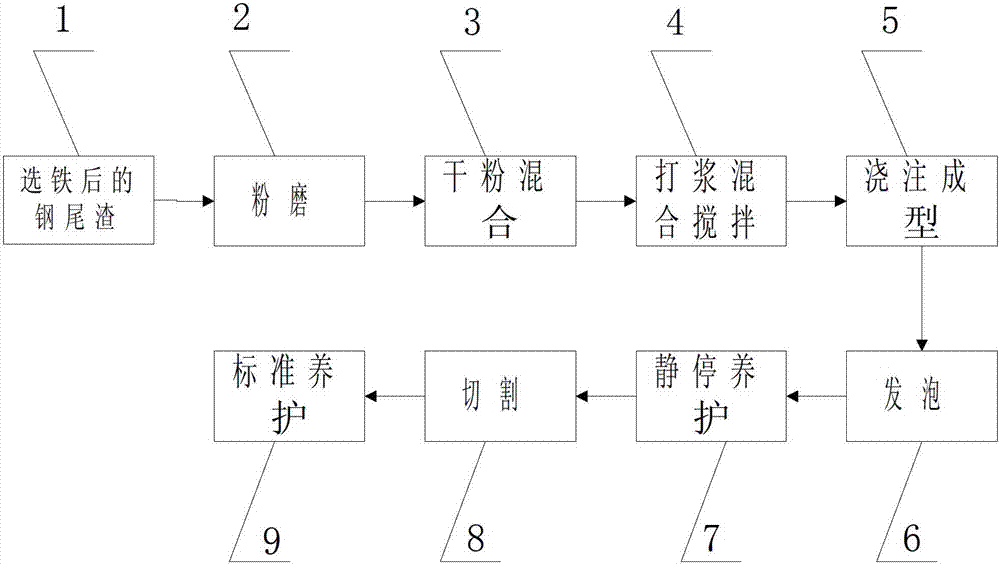

Method used

Image

Examples

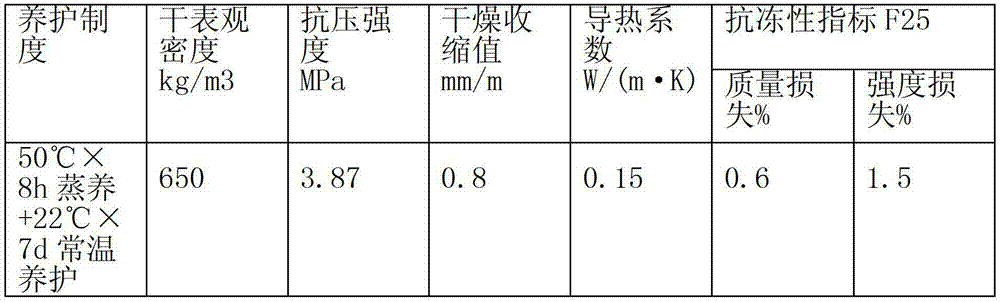

Embodiment 1

[0026] 1) After the water-quenched steel slag is subjected to conventional crushing, screening and magnetic separation processes, the composition requirements of the remaining steel tailings are: TFe (full iron) is 24%, MFe (metal iron) is 0.5%, f-CaO ( free calcium oxide) is 0.08%, f-MgO (free magnesium oxide) is 0.7%, SO 3 1%; the steel tailings after magnetic separation are classified and then dried, dried until the moisture content is ≤1%, and then ground until the specific surface area reaches 600cm 2 / g;

[0027] 2) Dry the slag obtained from blast furnace ironmaking after conventional water quenching until the moisture content is ≤1%, and then grind until the specific surface area reaches 360cm 2 / g;

[0028] 3) Mix the ground steel slag and slag powder with the cement clinker, gypsum and lime produced by the new dry process production line according to weight percentage: 30% of steel tailings fine powder, 45% of slag fine powder, and 10% of natural gypsum %, lime 5%...

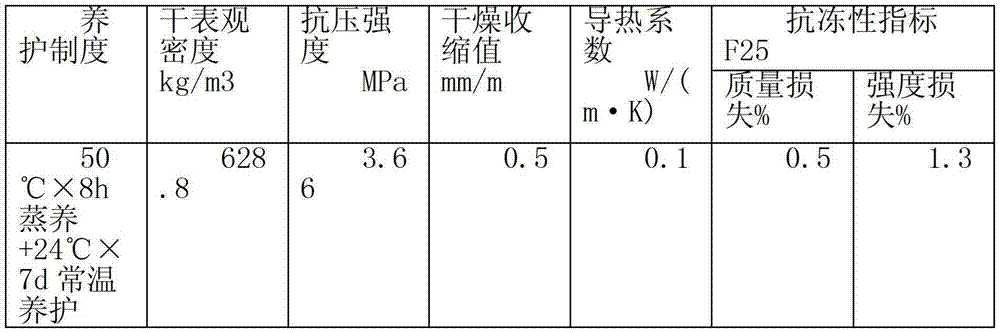

Embodiment 2

[0039] 1) After the water-quenched steel slag is subjected to conventional crushing, screening and magnetic separation processes, the composition requirements of the remaining steel tailings are: TFe (full iron) is 22%, MFe (metal iron) is 1%, f-CaO ( free calcium oxide) is 1%, f-MgO (free magnesium oxide) is 0.9%, SO 3 ≤2%. . The steel tailings after magnetic separation are classified and dried, dried until the moisture content is ≤1%, and then ground until the specific surface area reaches 660cm 2 / g.

[0040] 2) The slag obtained from blast furnace ironmaking is subjected to conventional water quenching to obtain slag with a particle size of ≤10mm, dried until the moisture content is ≤1%, and then ground until the specific surface area reaches 400cm 2 / g.

[0041] 3) Mix the finely ground steel slag and slag powder with the cement clinker, gypsum and lime produced by the new dry process production line according to weight percentage: 40% of steel tailings fine powder, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com