Bicomponent water-based nano waterproof coating and preparation method thereof

A waterproof coating and nano-waterproof emulsion technology, which is applied in the field of architectural coatings, can solve the problems of losing the waterproof performance of the waterproof layer, reducing the waterproof performance of the waterproof layer, and tile hollowing, achieving excellent permeability, overcoming tile hollowing, and improving adhesion. The effect of knot force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

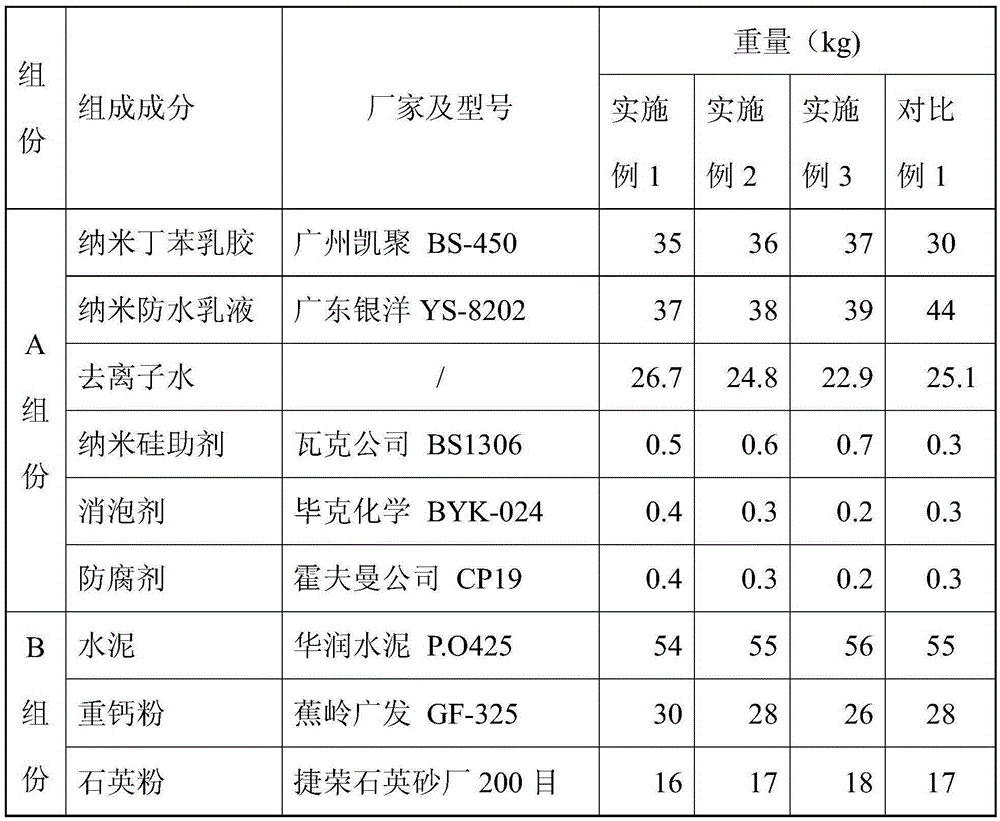

Embodiment 1

[0074] Component A:

[0075] 1. Add 35kg of nano-styrene-butadiene latex BS-450 from Guangzhou Kaiju Chemical Co., Ltd., 37kg of nano-waterproof emulsion YS-8202 from Guangdong Yinyang Resin Co., Ltd., and 26.7kg of deionized water into the production tank. Stir at 500 rpm for 15 minutes until uniform;

[0076] 2. Under stirring at a speed of 500 rpm, add 0.5 kg of nano-silicon additive of the model BS1306 of WACKER and BYK-024 of defoaming agent of BYK Chemicals in sequence. The preservative 0.4kg of agent 0.4kg, the model of Hoffman Company are CP19, stir 10min to uniform;

[0077] 3. Filter and package the finished product through a 100-mesh filter.

[0078] Component B

[0079] 1. Add the "China Resources-Runfeng" brand of China Resources Cement Holdings Co., Ltd., 54kg of cement of the model P.O425, 30kg of heavy calcium powder of the model GF-325 of Jiaoling County Guangfa Building Materials Co., Ltd., 16kg of 200-mesh quartz powder from Jierong Quartz Sand Factory i...

Embodiment 2

[0084] Component A:

[0085] 1. Add 36kg of nano-styrene-butadiene latex of model BS-450 from Guangzhou Kaiju Chemical Co., Ltd., 38kg of nano-waterproof emulsion of model YS-8202 from Guangdong Yinyang Resin Co., Ltd., and 24.8kg of deionized water into the production tank, 600 Stir for 10 min at rpm until uniform;

[0086] 2. Under stirring at 600 rev / min, add 0.6kg of nano-silicon additive of model BS1306 from WACKER, agent of Shenzhen Xinzhuneng Technology Co., Ltd., and defoamer of BYK-024 from BYK Chemicals. The preservative 0.3kg of agent 0.3kg, the model of Hoffman Company are CP19, stir 8min to even;

[0087] 3. Filter and package the finished product through a 100-mesh filter.

[0088] Component B:

[0089] 1. Add the "China Resources-Runfeng" brand of China Resources Cement Holdings Co., Ltd., 55kg of cement of the model P.O425, 28kg of heavy calcium powder of the model GF-325 of Jiaoling County Guangfa Building Materials Co., Ltd., 17kg of 200-mesh quartz powde...

Embodiment 3

[0094] Component A:

[0095] 1. Add 37kg of nano-styrene-butadiene latex of model BS-450 from Guangzhou Kaiju Chemical Co., Ltd., 39kg of nano-waterproof emulsion of model YS-8202 from Guangdong Yinyang Resin Co., Ltd., and 22.9kg of deionized water into the production tank, 700 Stir for 5 minutes at a rotating speed of rpm until uniform;

[0096] 2. Under stirring at a speed of 700 rpm, add 0.7kg of nano-silicon additive of the model BS1306 of WACKER and BYK-024 defoaming agent of BYK Chemicals in sequence. Antiseptic 0.2kg, Hoffman's model is CP19 preservative 0.2kg, stir 10min until uniform;

[0097] 3. Filter and package the finished product through a 100-mesh filter.

[0098] Component B:

[0099] 1. Add the "China Resources-Runfeng" brand of China Resources Cement Holdings Co., Ltd., 56kg of cement of the model P.O425, 26kg of heavy calcium powder of the model GF-325 of Jiaoling County Guangfa Building Materials Co., Ltd., 18kg of 200-mesh quartz powder from Jierong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com