Method for controlling crack of super-long wall body

A control method and wall technology, applied in the construction of super-long walls and construction fields, can solve the problem that prestressing technology is difficult to play an effective role, and achieve easy production and installation, reduction of wall shrinkage stress, and construction procedures. concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

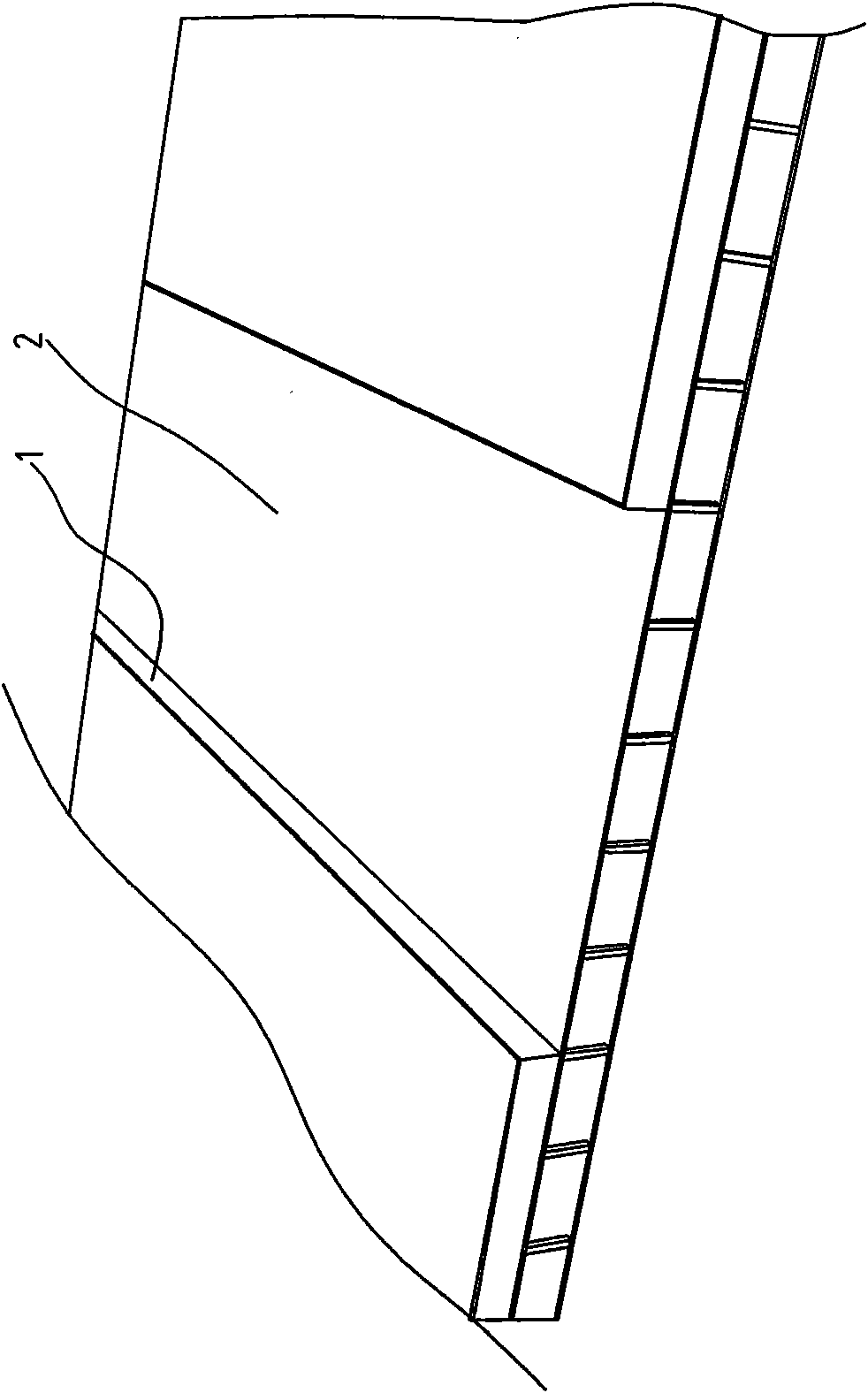

[0026] Such as figure 1 As shown, the method of the present invention is applied in the Phase 2 project of a certain business district. The project is a large-area underground two-story garage structure with a construction area of about 70,000 m 2 , the basement is 256.8m long and 132.8-165m wide, and it is a two-way prestressed frame structure. Higher requirements.

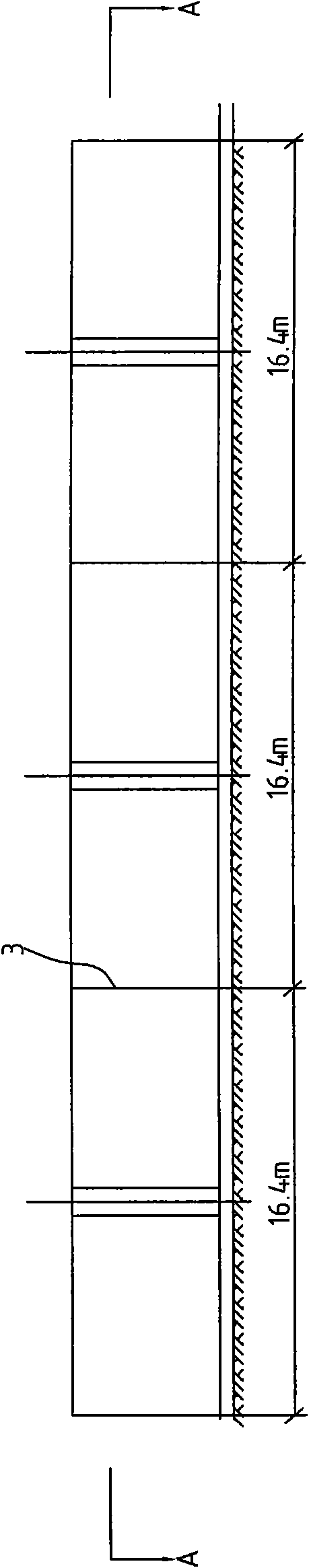

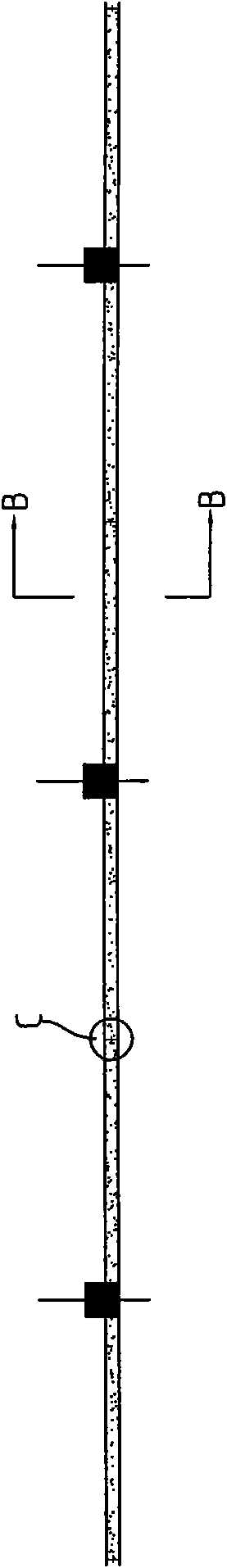

[0027] Such as figure 1 As shown, the water depth of the artificial river 2 is 3m, the height of the side wall panel 1 of the river is 3.1m, and the thickness is 300mm. C30 concrete is used, and 1φ s 15.24@300 unbonded prestressed tendons. In order to reduce the shrinkage stress in the wall, 12 non-bonding ribs 5 are evenly arranged in the joist (b×h=400mm×1100mm) arranged at the bottom of the wallboard. The bottom slab of the river course is the roof of the bottom garage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com