Gum dipping device and method for improving performance of optical fiber coil

A technology of optical fiber coils and dipping devices, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of not forming products, staying, gaps, etc., and achieve the effects of reducing shrinkage stress, improving temperature stability and anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

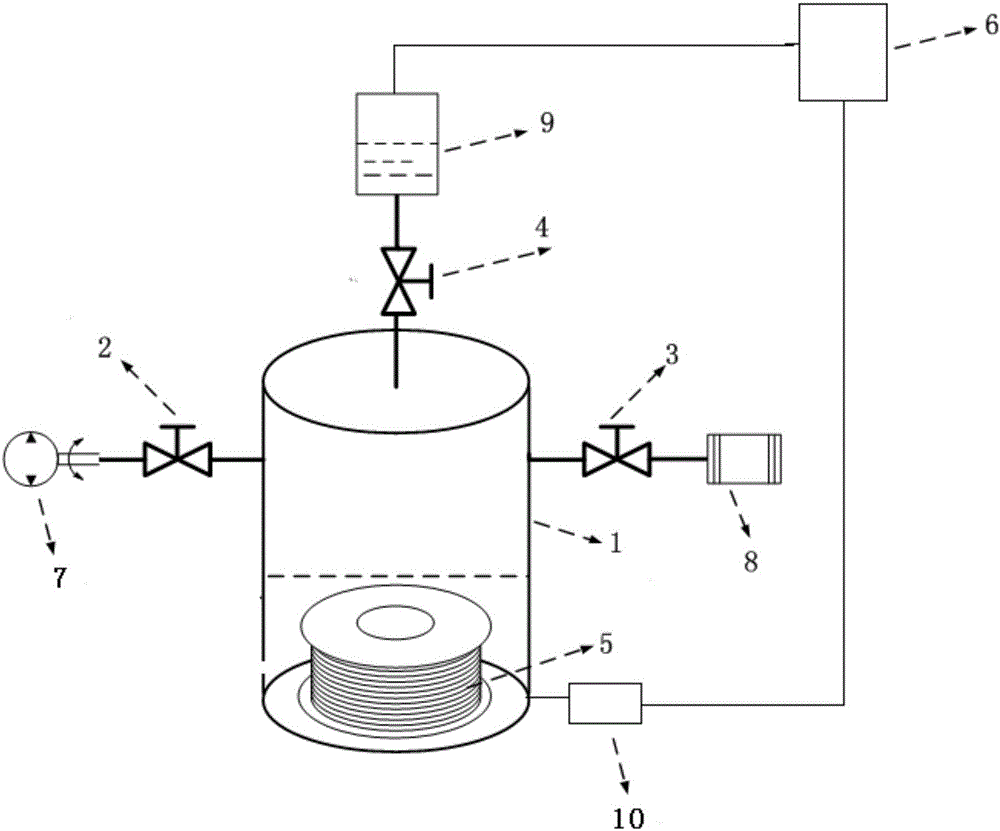

[0056] Add 100 parts of polysiloxane containing vinyl, 100 parts of dimethyl polysiloxane containing Si-H bond, and 1.6 parts of platinum catalyst into the beaker, put it on a high-strength magnetic stirrer and stir it for 10 minutes, and let it stand for 15 minutes Finally, put it in a vacuum defoaming box for 20 minutes, then transfer it to the glue container on the upper part of the dipping tank, and wait for 10 minutes to absorb the glue.

[0057] Place the optical fiber coil to be dipped in the bottom of the vacuum pressure impregnation tank, close the cover and seal it, turn on the vacuum pump and open the vacuum valve to vacuum the inside of the tank, when the vacuum reaches below 100Pa, continue to vacuum for 2 hours, and then open the upper connection The glue suction valve of the glue container, slowly suck the adhesive into the bottom of the tank until it completely submerges the optical fiber coil, close the glue suction valve, continue vacuuming the tank for 1 hour...

Embodiment 2

[0063] Add 50 parts of A polysiloxane containing vinyl groups, 50 parts of dimethylpolysiloxane containing Si-H bonds, and 0.8 parts of platinum catalyst into a beaker, place it on a high-intensity magnetic stirrer and stir it for 18 minutes, and let it stand After 13 minutes, put it in a vacuum degassing box for 16 minutes, then transfer it to the glue container on the upper part of the dipping tank, and wait for 8 minutes to absorb the glue.

[0064] Place the optical fiber coil to be dipped in the bottom of the vacuum pressure impregnation tank, close the cover and seal it, then turn on the vacuum pump and open the vacuum valve to vacuum the inside of the tank. When the vacuum reaches 10-2Pa, continue to vacuum for 4 hours, and then open the upper part Connect the glue suction valve of the glue container, slowly suck the adhesive into the bottom of the tank until it completely submerges the optical fiber coil, close the glue suction valve, continue vacuuming the tank for 0.5...

Embodiment 3

[0071] Add 100 parts of epoxy resin prepolymer compound and 10 parts of acid anhydride curing agent into a beaker, put it on a high-strength magnetic stirrer and stir it for 20 minutes, let it stand for 20 minutes, put it in a vacuum defoaming box for 15 minutes, and then transfer it to the impregnation In the glue container 9 on the top of the tank body 1, place it for 20 minutes to wait for glue suction.

[0072] Place the optical fiber coil 5 to be dipped in the bottom of the vacuum pressure impregnation tank 1, close the cover and seal it, then turn on the vacuum pump 7 and open the vacuum valve 2 to vacuumize the inside of the tank, and continue vacuuming for 3 hours after the vacuum degree reaches below 50Pa. Then open the upper glue-absorbing valve 4 connected to the glue container 9, slowly suck the adhesive into the bottom of the tank until the optical fiber coil 5 is completely submerged, close the glue-absorbing valve 4, and continue vacuuming the tank for 0.8h, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com