A kind of method for preparing borazine

A borazane and nitrogen filling technology, which is applied in the field of preparing borazane, can solve the problems of low temperature, reduced borazane yield, inability to produce borazane with high yield and high yield, etc., and achieves high yield , the effect of major economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

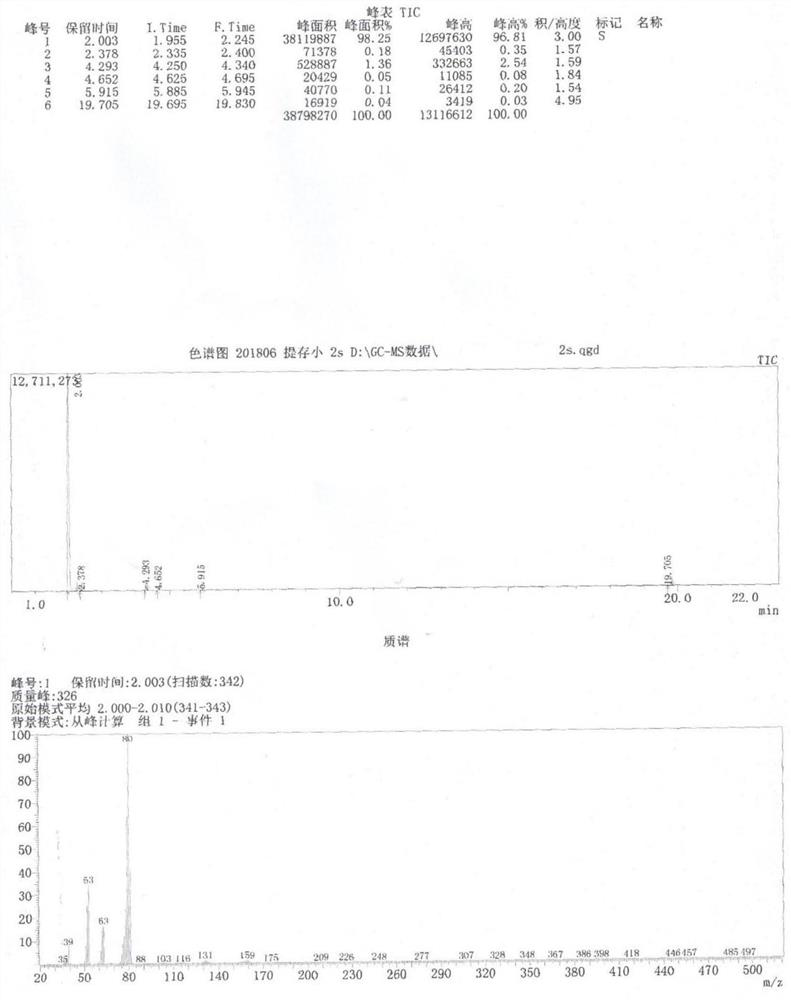

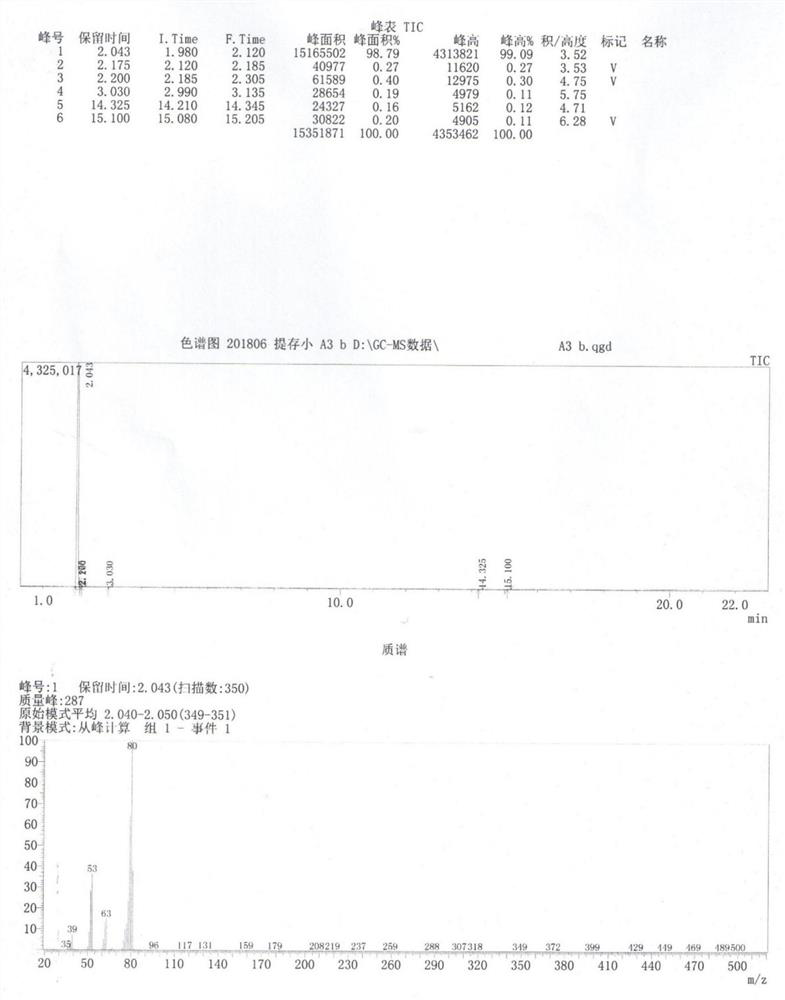

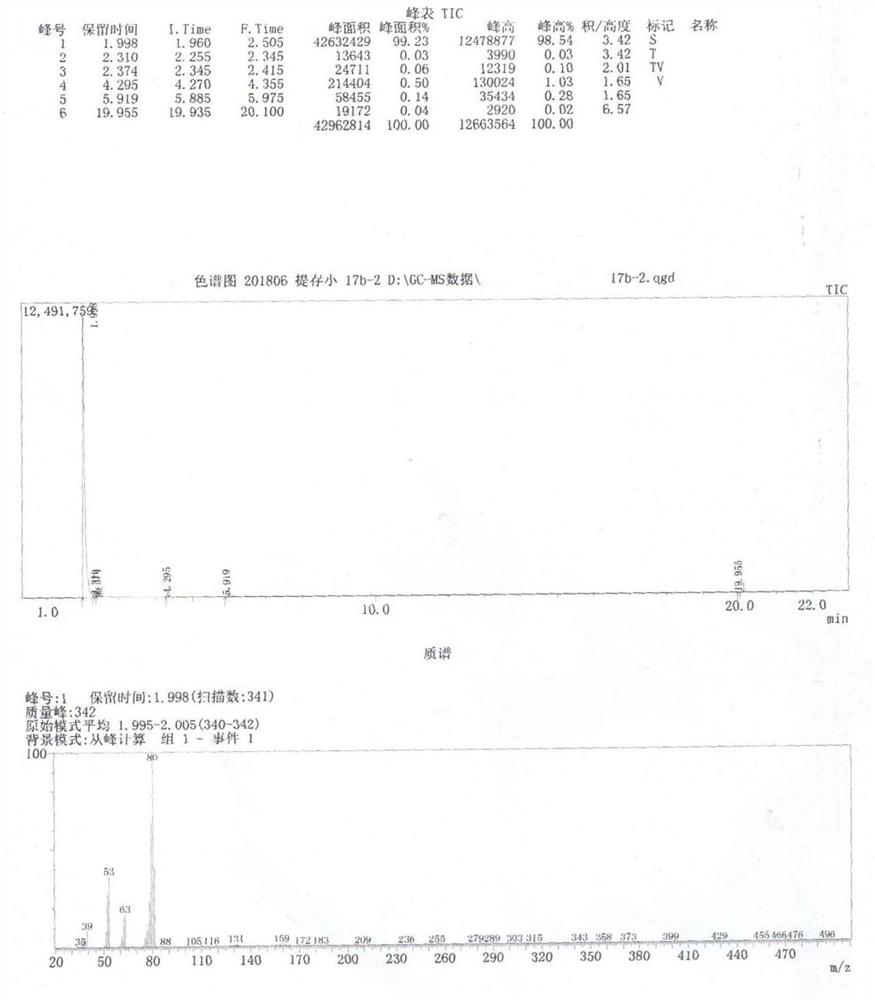

Image

Examples

Embodiment 1

[0029]A kind of method for preparing borazine described in the present embodiment, concrete steps are as follows:

[0030] The first step, mix 22kg tetrahydrofuran and 22kg tetraethylene glycol dimethyl ether, and cool to 0°C, add 28kg ammonium sulfate and 14.5kg sodium borohydride, vacuumize the reaction system, fill it with nitrogen, vacuumize it, and fill it with nitrogen 1. Vacuumize and fill with nitrogen to replace the air in the system, then add liquid ammonia with a molar mass of 1% borohydride ion, and fully stir for 3 hours;

[0031] The second step is to raise the temperature of the reaction system to 25°C and fully stir the reaction for 2.5h;

[0032] The third step is to raise the temperature of the reaction system to 60°C, vacuumize the reaction system while raising the temperature, and fully stir the reaction at 60°C for 3 hours, and collect the gas generated by the reaction;

[0033] The fourth step is to use a cold trap to cool the gas generated by the reacti...

Embodiment 2

[0037] A kind of method for preparing borazine described in the present embodiment, concrete steps are as follows:

[0038] The first step, mix 29kg tetrahydrofuran and 58kg tetraethylene glycol dimethyl ether, and cool to 0°C, add 32kg ammonium sulfate and 14.5kg sodium borohydride, vacuumize the reaction system, fill it with nitrogen, vacuumize it, and fill it with nitrogen 1. Vacuumize and fill with nitrogen to replace the air in the system, then add liquid ammonia with a molar mass of 6% borohydride ion, and fully stir and react for 1.5h;

[0039] The second step is to raise the temperature of the reaction system to 30°C and fully stir the reaction for 0.5h;

[0040] The third step is to raise the temperature of the reaction system to 80°C, vacuumize the reaction system while raising the temperature, and fully stir the reaction at 80°C for 1.5h, and collect the gas generated by the reaction;

[0041] The fourth step is to use a cold trap to cool the gas generated by the r...

Embodiment 3

[0045] A kind of method for preparing borazine described in the present embodiment, concrete steps are as follows:

[0046] The first step, mix 44kg tetrahydrofuran and 22kg tetraethylene glycol dimethyl ether, and cool to 0°C, add 35.4kg ammonium sulfate and 14.5kg sodium borohydride, vacuumize the reaction system, fill with nitrogen, vacuumize, fill Nitrogen, vacuumize, and fill with nitrogen to replace the air in the system, then add liquid ammonia with a molar mass of 3% borohydride ions, and fully stir the reaction for 0.5h;

[0047] In the second step, the temperature of the reaction system is raised to 20°C, and the reaction is fully stirred for 5 hours;

[0048] The third step is to raise the temperature of the reaction system to 100°C, vacuumize the reaction system while raising the temperature, and fully stir the reaction at 100°C for 1.5h, and collect the gas generated by the reaction;

[0049] The fourth step is to use a cold trap to cool the gas generated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com