A low temperature processable radiation crosslinked ethylene-tetrafluoroethylene copolymer material

A technology of tetrafluoroethylene and cross-linked ethylene, which is applied in the field of radiation cross-linked ethylene-tetrafluoroethylene copolymer materials, can solve the problems of poor thermal stability, darkening of color, and demanding processing temperature, so as to improve the cross-linking effect and Stability, high elongation at break, low processing temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

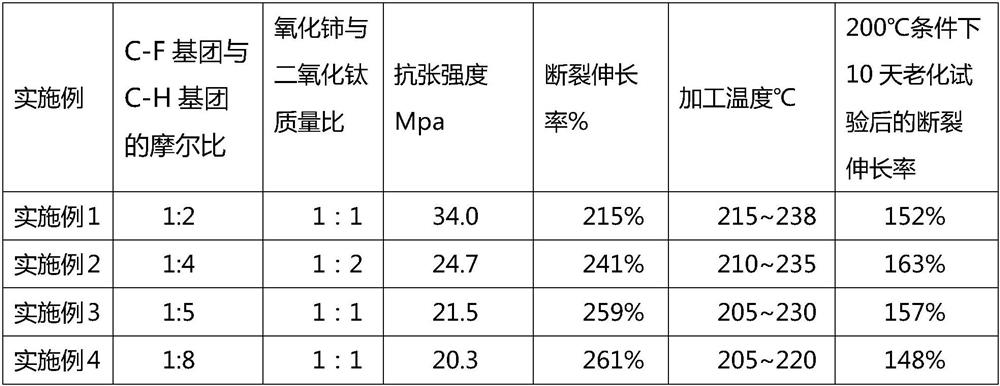

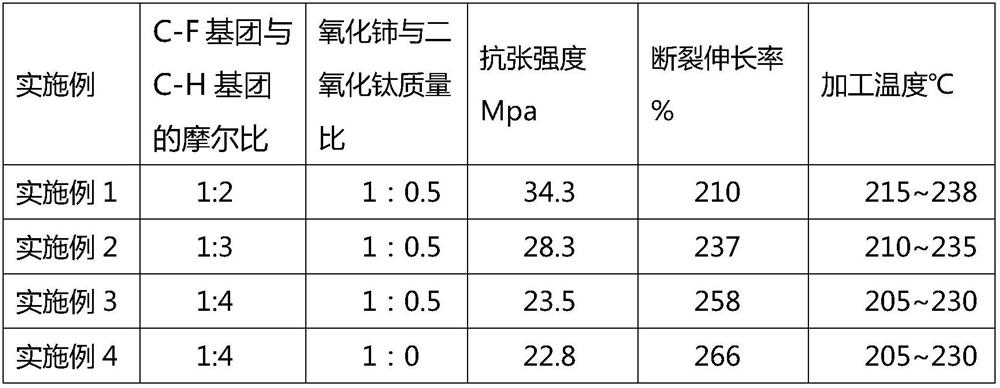

Embodiment 1

[0022] The material components of Example 1 are: 100 parts of ETFE, wherein the molar ratio of C-F group to C-H group is 1:2, 0.5 part of TMPTMA, 1 part of TAIC, 1 part of cerium oxide, 1 part of titanium dioxide, antioxidant 1330 2 parts, 0.4 parts of antioxidant 1024, 5 parts of antimony trioxide, 1 part of pentaerythritol stearate, 0.5 parts of N'N-ethylene bisstearamide, 1.5 parts of white oil.

Embodiment 2

[0024] The preparation material components of Example 2 are: 100 parts of ETFE, wherein the molar ratio of C-F groups to C-H groups is 1:4, 1 part of TMPTMA, 1 part of TAIC, 1 part of cerium oxide, 2 parts of titanium dioxide, antioxidant 2 parts of 1330, 0.4 parts of antioxidant 1024, 5 parts of antimony trioxide, 1 part of pentaerythritol stearate, 0.5 parts of N'N-ethylene bisstearamide, and 1.5 parts of white oil.

Embodiment 3

[0026] The prepared material components of Example 3 are: 100 parts of ETFE, wherein the molar ratio of C-F groups to C-H groups is 1:5, 1.5 parts of TMPTMA, 1 part of TAIC, 2 parts of cerium oxide, 2 parts of titanium dioxide, antioxidant 2 parts of 1330, 0.4 parts of antioxidant 1024, 5 parts of antimony trioxide, 1 part of pentaerythritol stearate, 0.5 parts of N'N-ethylene bisstearamide, 1.5 parts of white oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com