Method for synthesizing BTX aromatic methyl into unsym-trimethyl benzene

A technology for BTX aromatics and trimethylene, which is applied in the fields of condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, organic chemistry, and isomerization to hydrocarbons, etc. It can solve the problems of no industrial application prospect and low yield of trimethylene. , to achieve good industrial application prospects, low cost of raw materials, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of molecular sieve catalyst:

[0025]Separate preparation of SiO by hydrothermal synthesis 2 / Al 2 o 3 =55 NaZSM-5, SiO 2 / Al 2 o 3 =30 NaZSM-22, SiO 2 / Al 2 o 3 =50 NaMCM-22, SiO 2 / Al 2 o 3 =25 NaMCM-49, SiO 2 / Al 2 o 3 =25 NaMCM-56 molecular sieve and SiO 2 / Al 2 o 3 =30 Naβ molecular sieve, the resulting molecular sieve is exchanged with ammonium chloride, washed and roasted, then pressed into tablets and sieved to get a certain number of particles to obtain hydrogen molecular sieve catalysts HZSM-5, HZSM-22, HMCM-22, HMCM -49, HMCM-49, HMCM-56 and Hβ are used as catalysts for the synthesis of trimethylene by alkylation.

Embodiment 2~7

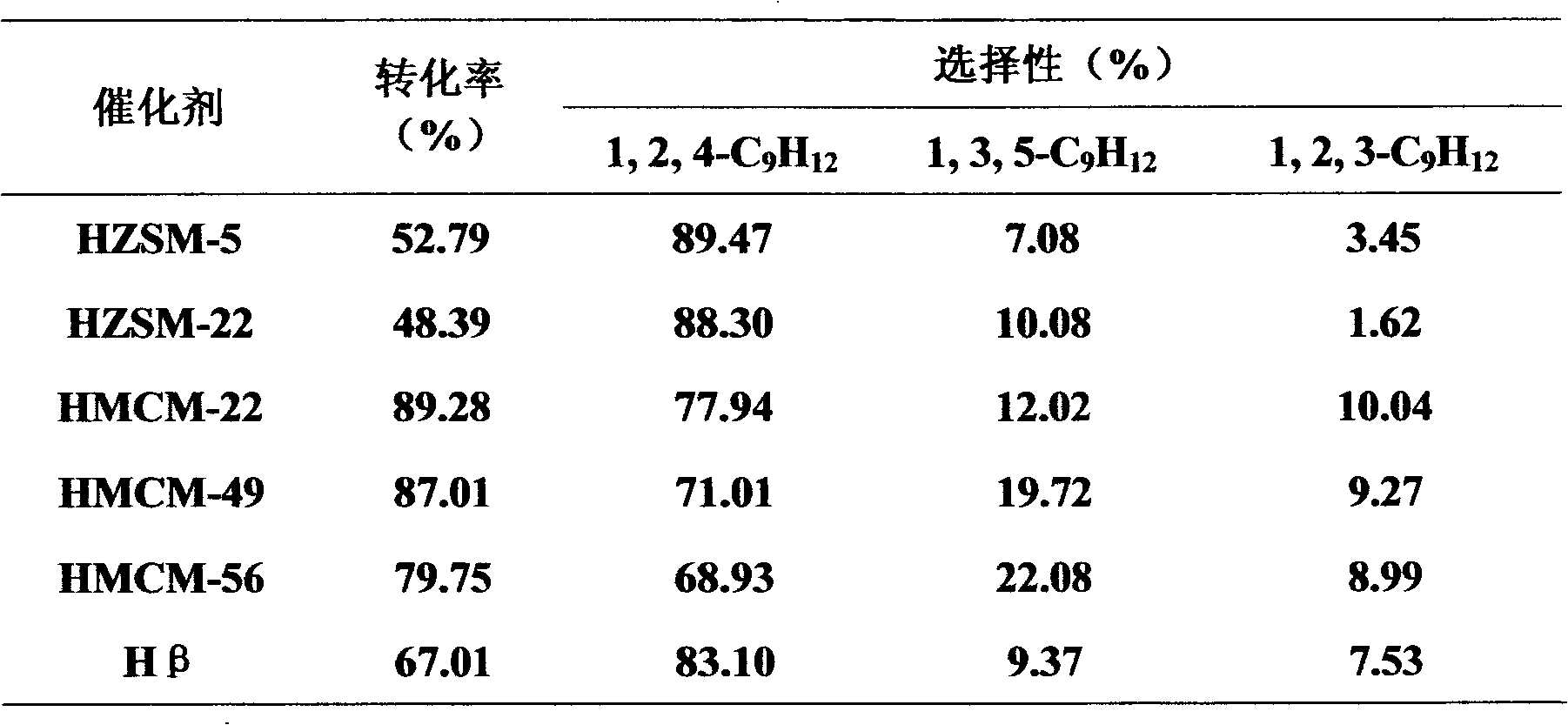

[0027] The catalyst prepared in Example 1 was applied to the alkylation reaction of toluene and methanol to synthesize trimitylene, and the fixed-bed continuous reaction was adopted. The reaction conditions are: temperature 350°C, liquid mass space velocity 1h -1 , Benzene: Methanol (molar ratio) 1:2, the reaction time is 1 hour, normal pressure. The reaction results are shown in Table 2.

[0028] Table 2 Reaction performance of toluene and methanol alkylation to synthesize mesitylene on different catalysts

[0029]

Embodiment 8~10

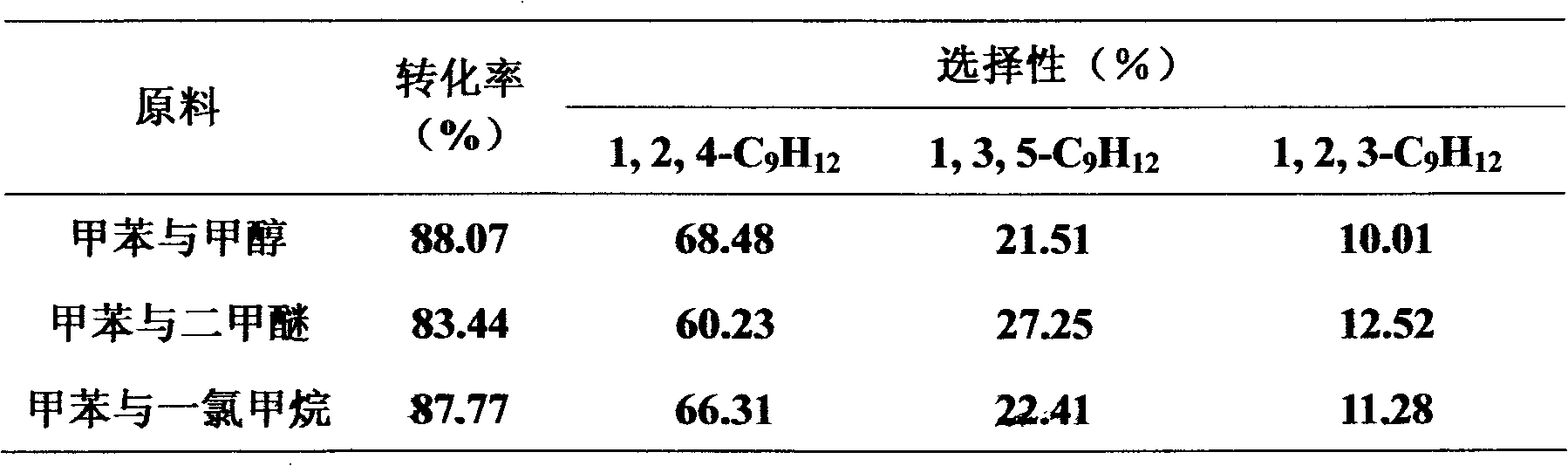

[0031] Toluene is alkylated with methanol, dimethyl ether or methylene chloride to synthesize trimitylene, and the fixed-bed continuous reaction is adopted.

[0032] Reaction conditions: temperature 400°C, liquid mass space velocity 1h -1 , toluene: methanol or methyl chloride (molar ratio) 1:2, toluene: dimethyl ether (molar ratio) 1:1, the reaction time is 1 hour, normal pressure. The catalyst is SiO 2 / Al 2 o 3 =50 HMCM-22 molecular sieve. The reaction results are shown in Table 3.

[0033] Table 3 Reaction performance of toluene alkylation to synthesize mesitylene on HMCM-22 catalyst

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com