High-adhesion high-gloss black UV inkjet ink and preparation method and application thereof

A high-adhesion, inkjet ink technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of short shelf life, increased viscosity of UV ink, late start, etc., and achieve short preparation time, good gloss and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

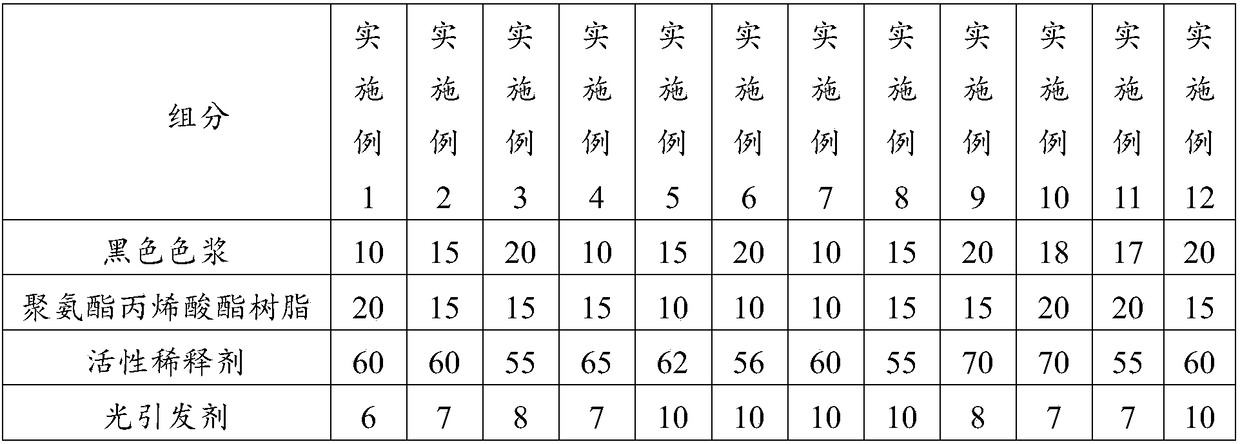

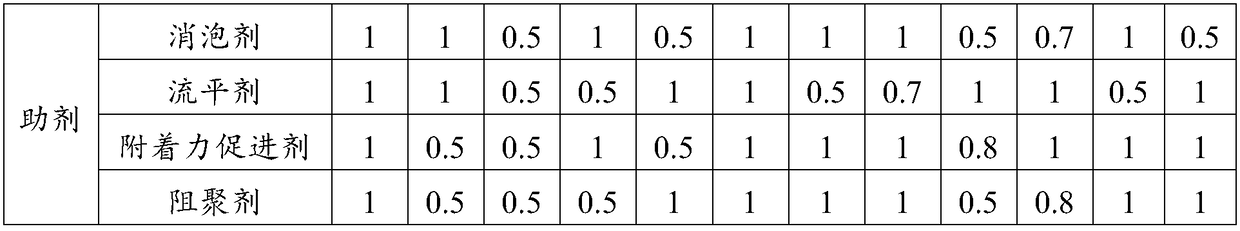

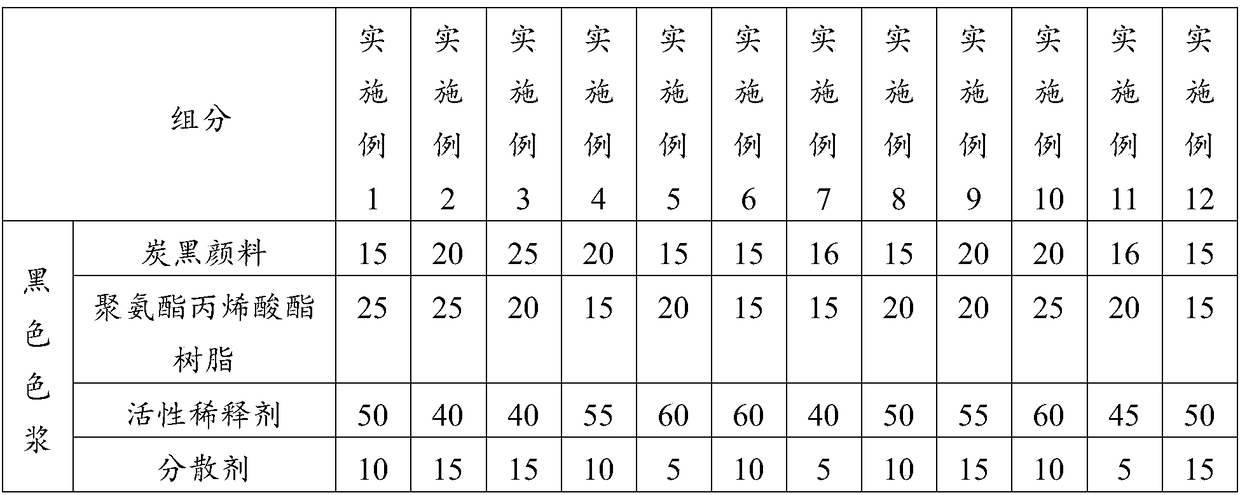

[0038] The present invention will be described in further detail below in conjunction with specific embodiments.

[0039] According to the proportioning relationship in Table 1 to Table 9, add polyurethane acrylate resin, active diluent and dispersant to the reaction kettle in proportion, and then stir and disperse with a disc stirring paddle. The dispersion time is 20 to 30 minutes. The dispersion system Control the temperature at 20°C to 40°C to obtain component A.

[0040] Add carbon black pigment to component A in proportion, and then stir and disperse with a disc stirring paddle. The dispersion time is 20-30 minutes, and the temperature of the dispersion system is controlled at 20°C-40°C to obtain component B.

[0041] Add component B into the grinder for high-speed grinding. The grinding time is 60-90 minutes. The temperature of the grinding system is controlled at 20°C-40°C to obtain a black color paste.

[0042]Add black color paste and urethane acrylate resin into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com