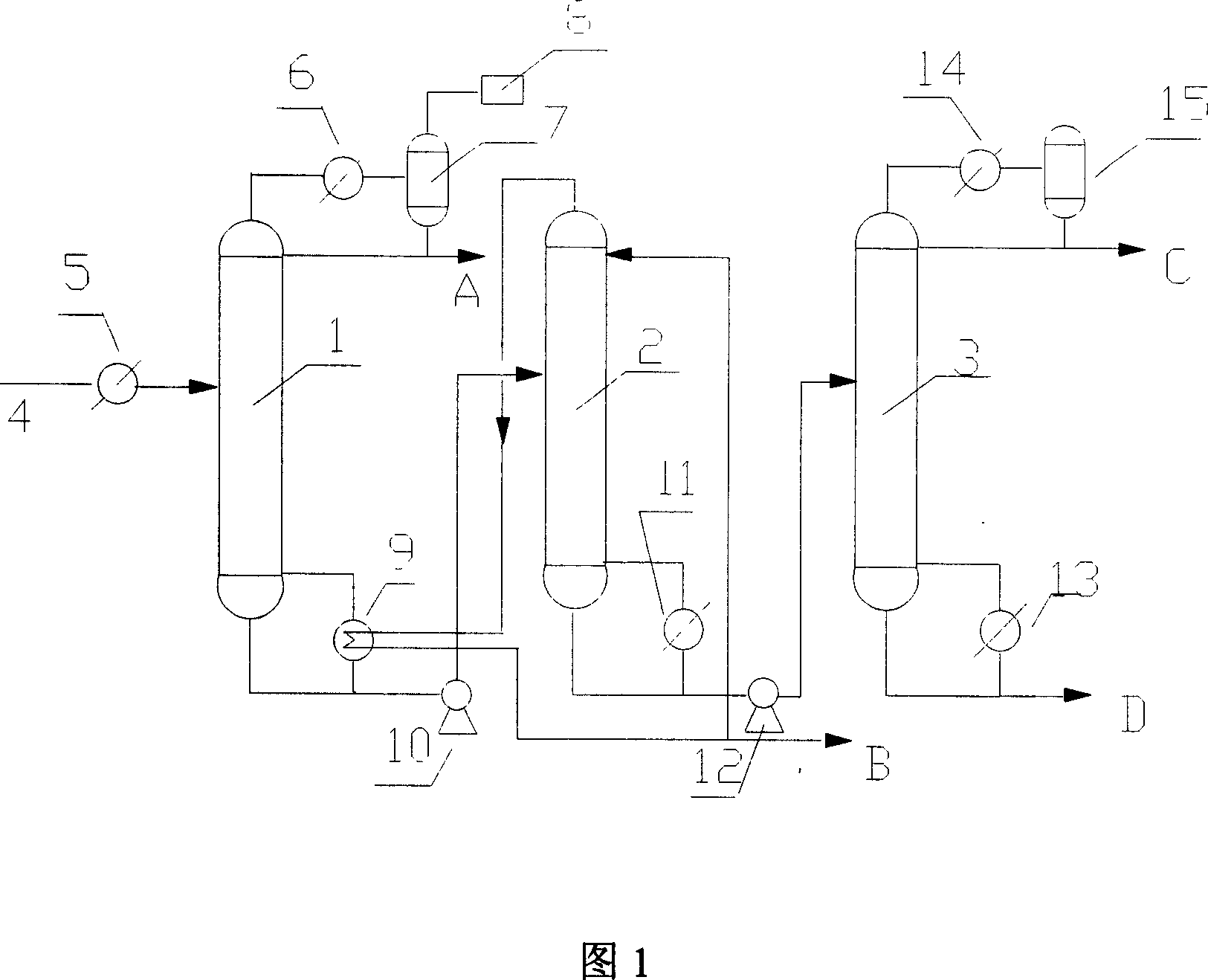

Serial trimethyl benzene separating apparatus and method

A separation device and separation method technology, applied in distillation purification/separation, fractionation, organic chemistry and other directions, can solve the problems of high energy consumption, difficult separation, high investment and operating costs, and achieve the effect of reducing unit energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

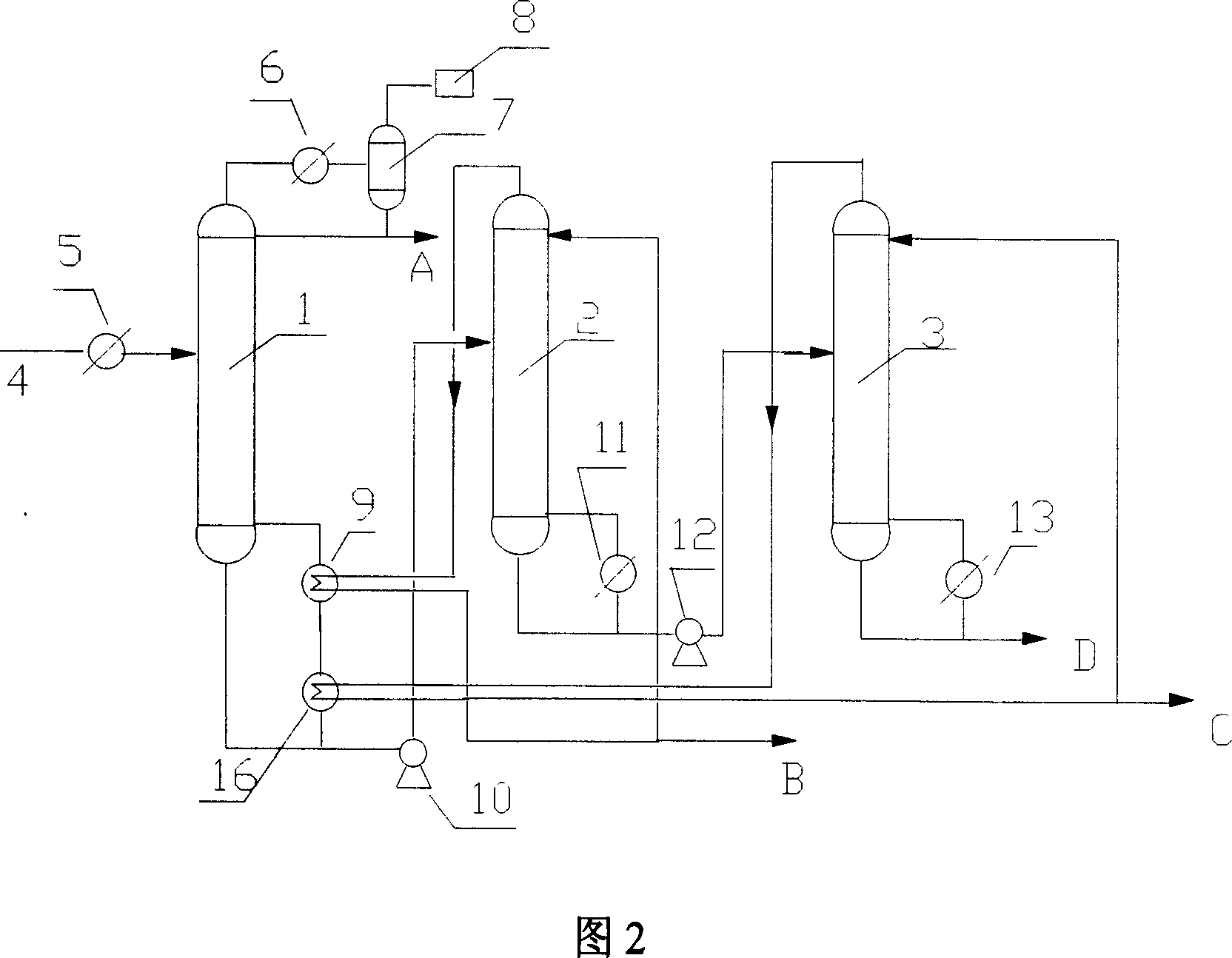

[0021] The pre-separation tower, the mesitylene tower and the partial toluene tower all use metal mesh corrugated packing. The thermal coupling process is to realize thermal coupling between the pre-separation tower and the mesitylene tower and the partial toluene tower, as shown in Figure 2. The C9 aromatic hydrocarbon raw material 4 enters the pre-separation tower 1 after heat exchange by the heat exchanger 5, and the pre-separation tower is operated at 30KPa, and the temperature at the top of the tower is controlled at 100°C. The top of the tower is connected to a vacuum device 8, and the gas phase at the top of the tower passes through a condenser 6 Then enter the reflux tank 7, wherein the condensate is partly refluxed, partly as light solvent oil A out of bounds. The pressure of the mesitylene tower is controlled at 100KPa, and the temperature at the top of the tower is controlled above 150°C, so that the gas phase at the top of the tower is used as the heat source of th...

Embodiment 2

[0023] The pre-separation tower, the mesitylene tower and the partial toluene tower all use metal mesh corrugated packing. The thermal coupling process is to realize thermal coupling between the pre-separation tower and the mesitylene tower and the partial toluene tower, as shown in Figure 2. The C9 aromatic hydrocarbon raw material 4 enters the pre-separation tower 1 after heat exchange by the heat exchanger 5. The pre-separation tower is operated at 50KPa, and the temperature at the top of the tower is controlled at 130°C. The top of the tower is connected to a vacuum device 8, and the gas phase at the top of the tower passes through a condenser 6 Then enter the reflux tank 7, wherein the condensate is partly refluxed, partly as light solvent oil A out of bounds. The pressure of the mesitylene tower is controlled at 120KPa, and the temperature at the top of the tower is controlled at about 170°C, so that the gas phase at the top of the tower is used as the heat source of the...

Embodiment 3

[0025] The pre-separation tower, the mesitylene tower and the partial toluene tower all use metal mesh corrugated packing. The thermal coupling process is to realize thermal coupling between the pre-separation tower and the mesitylene tower and the partial toluene tower, as shown in Figure 2. The C9 aromatic hydrocarbon raw material 4 enters the pre-separation tower 1 after heat exchange by the heat exchanger 5, and the pre-separation tower is operated at 80KPa, and the temperature at the top of the tower is controlled at 160°C. The top of the tower is connected to a vacuum device 8, and the gas phase at the top of the tower passes through a condenser 6 Then enter the reflux tank 7, wherein the condensate is partly refluxed, partly as light solvent oil A out of bounds. The pressure of the mesitylene tower is controlled at 160KPa, and the temperature at the top of the tower is controlled at 185°C, so that the gas phase at the top of the tower is used as the heat source of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com