Method for preparing mesoporous SBA-15 unstuck micro spheres

A microsphere and mesoporous technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of high adhesion and poor dispersibility of mesoporous SBA-15 microspheres, and achieve the effect of preventing adhesion and large pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

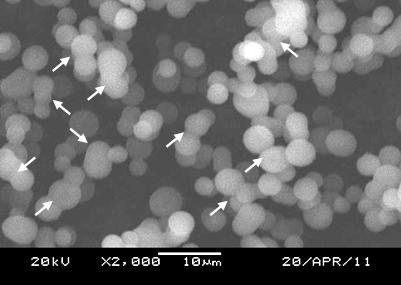

Embodiment 1

[0025] (1) Take 2.0 g of P123 and 1.5 g of KCl, add it to a 100 mL beaker filled with 72 g of 1.7 mol / L hydrochloric acid, heat to 40°C, and magnetically stir for 4 h until clarification;

[0026] (2) Then lower the temperature to 26°C, add 1.2 g of TMB, continue stirring for 10 h, add 4.2 g of TEOS dropwise, add 0.0 g of PVA, stop stirring after dissolving; raise the temperature to 40°C, and let stand for 20 hours;

[0027] (3) Transfer the above mixture to a 100 mL hydrothermal kettle (lined with polytetrafluoroethylene), add 0.025 g of NH 4 After F, seal the kettle, and conduct static hydrothermal crystallization at 100° C. for 24 hours. After cooling, the obtained product was filtered, washed with distilled water to remove soluble components, dried at 60°C for 4 h, and then calcined at 550°C for 6 hours to completely remove the template agent and the like to obtain mesoporous SBA-15 microspheres.

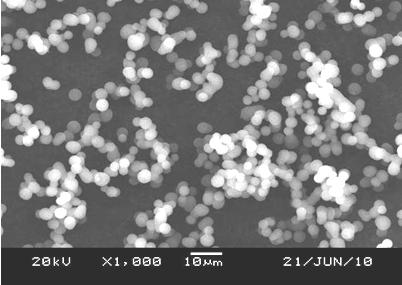

Embodiment 2

[0029] (1) Take 2.0 g of P123 and 1.5 g of KCl, add it to a 100 mL beaker filled with 72 g of 1.7 mol / L hydrochloric acid, heat to 40°C, and magnetically stir for 4 h until clarification;

[0030] (2) Then lower the temperature to 26°C, add 1.2 g of TMB, continue stirring for 10 h, add 4.2 g of TEOS dropwise, add 0.5 g of PVA, stop stirring after dissolving; raise the temperature to 40°C, and let stand for 20 hours;

[0031] (3) Transfer the above mixture to a 100 mL hydrothermal kettle (lined with polytetrafluoroethylene), add 0.025 g of NH 4 After F, seal the kettle, and conduct static hydrothermal crystallization at 100° C. for 24 hours. After cooling, the obtained product was filtered, washed with distilled water to remove soluble components, dried at 60°C for 4 h, and then calcined at 550°C for 6 hours to completely remove the template agent, etc., to obtain non-adhesive mesoporous SBA-15 microspheres.

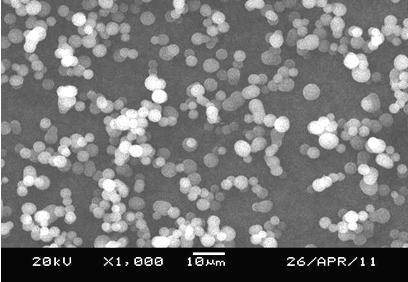

Embodiment 3

[0033](1) Take 2.0 g of P123 and 1.5 g of KCl, add it to a 100 mL beaker filled with 72 g of 1.7 mol / L hydrochloric acid, heat to 40°C, and magnetically stir for 4 h until clarification;

[0034] (2) Then lower the temperature to 26°C, add 1.2 g of TMB, continue stirring for 10 h, add 4.2 g of TEOS dropwise, add 1.0 g of PVA, stop stirring after dissolving; raise the temperature to 40°C, and let stand for 20 hours;

[0035] (3) Transfer the above mixture to a 100 mL hydrothermal kettle (lined with polytetrafluoroethylene), add 0.025 g of NH 4 After F, seal the kettle, and conduct static hydrothermal crystallization at 100° C. for 24 hours. After cooling, the obtained product was filtered, washed with distilled water to remove soluble components, dried at 60°C for 4 h, and then calcined at 550°C for 6 hours to completely remove the template agent, etc., to obtain non-adhesive mesoporous SBA-15 microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com