Magnetic silica airgel and its preparation method by normal pressure drying

An atmospheric drying and aerogel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of difficult industrial production, cumbersome operation, long preparation period, etc., and achieve the effect of improving stability and excellent magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A kind of magnetic SiO of the present invention 2 The preparation method of airgel comprises the steps:

[0047] (1) Partially hydrolyze orthosilicate to form various polysiloxanes;

[0048] (2) Mix the polysiloxane with magnetic nanoparticles, alcohol or ketone, and alkali catalyst evenly to form alcohol gel or ketone gel;

[0049] (3) After crushing the alcohol gel or ketone gel into powder or granular form, mix and stir with liquid alkane or fluoroalkane to replace the alcohol or ketone in the alcohol gel or ketone gel, thereby Obtain an alkane gel;

[0050] (4) mixing and stirring the alkane gel with a mixed solution of a hydrophobic agent and a liquid alkane to obtain a hydrophobic alkane gel;

[0051] (5) Dry the hydrophobic alkane gel under normal pressure to obtain magnetic SiO 2 airgel.

[0052] Wherein, in a more specific embodiment, the magnetic SiO 2 Airgel preparation methods may include:

[0053] (1) Mix and stir orthosilicate, hydrolysis catalyst, ...

Embodiment 1

[0076] (1) Preparation of CS silicone oil: 1 mole of methyl orthosilicate, 1.3 moles of dilute acid solution (10 -3 mol / L), ethanol (150ml) mixed, refluxed for later use after 8 hours.

[0077] (2) Magnetic SiO 2 Synthesis of composite gel: take 10 parts of CS silicone oil, 12 parts of ethanol and 1wt% Fe 3 o 4 The magnetic nanoparticles were placed in a stirring tank, and 1 ml of ammonia water was added dropwise under stirring at a stirring speed of 150 rpm, and an alcohol gel was formed after stirring for 5 minutes.

[0078] (3) Solvent replacement and hydrophobization treatment of gel particles: After crushing the alcohol gel, add 100ml of n-hexane, stir for 4 hours, filter, then put the gel particles in 100ml of n-hexane, and slowly add 8ml of hexamethyl di Silamine, stirred for 2 hours, and filtered to obtain surface hydrophobized modified alkane gel particles.

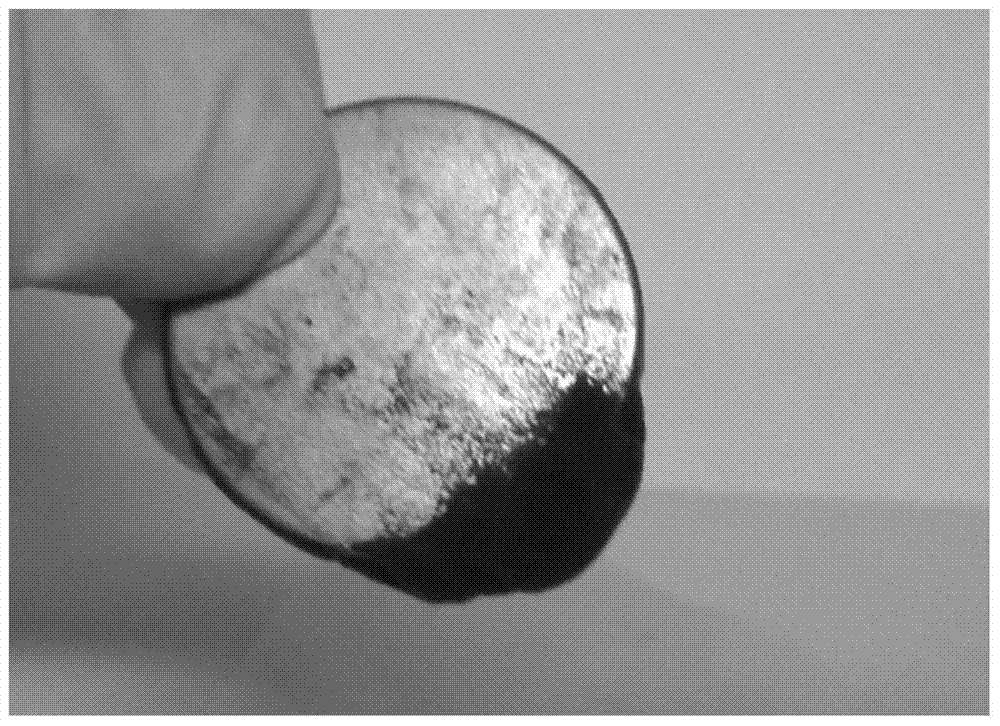

[0079] (4) Drying of wet gel particles: the surface hydrophobized modified gel particles are dried in a bl...

Embodiment 2

[0081](1) Preparation of CS silicone oil: 1 mole of methyl orthosilicate, 1.5 mole of dilute acid solution (concentration 10 -2 mol / L), ethanol (80ml) mixed, refluxed after 16 hours for subsequent use.

[0082] (2) Magnetic SiO 2 Synthesis of composite gel: Take 10 parts of CS silicone oil, 20 parts of ethanol, and 1 wt% of FeN magnetic nanoparticles, add 1.50 ml of ammonia water dropwise under stirring at 800 rpm, and form alcohol gel after stirring for 5 minutes.

[0083] (3) Solvent replacement and hydrophobization treatment of gel particles: crush the alcohol gel, add 150ml of n-hexane, stir for 4 hours, filter, then put the gel particles in 150ml of n-hexane, and slowly add 10ml of hexamethyl di Silamine, stirred for 2 hours, and filtered to obtain surface hydrophobized modified alkane gel particles.

[0084] (4) Drying of wet gel particles: the surface hydrophobized modified gel particles are dried in a blast dryer, the temperature is controlled at 80°C, and magnetic S...

PUM

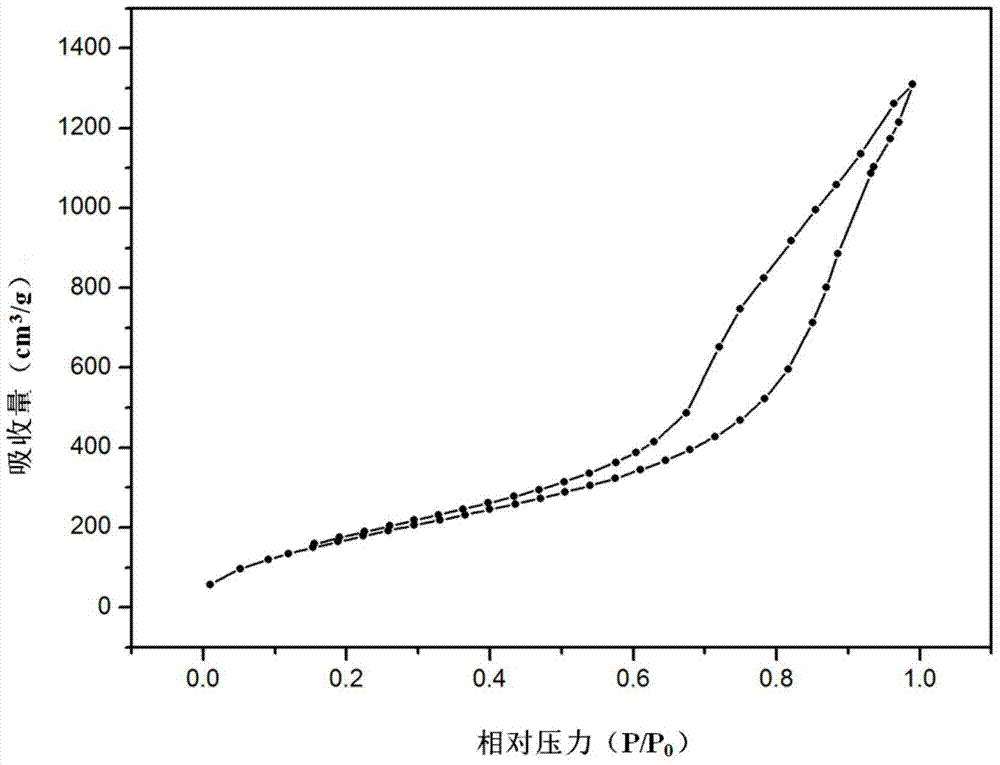

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com